Printing Steel for Decoration JIS 3312 CGCC ASTM A653

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

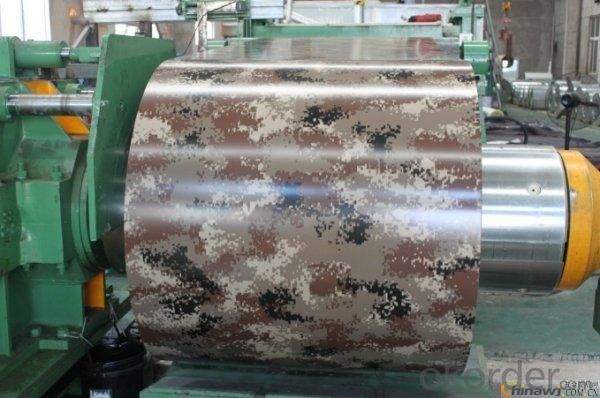

Printing steel plate is the product based on the metal sheet, of which surface is finally installed of the plastic film(PVC,PE) in addition to being firstly covered with the coating and printed ink in. The coated layer of printing steel olate consists of chemical and filming layer, primer coated layer, pattern printed lay and surface coated layer.The top and back coating shall generally be the application of the weatherproof paint, as well can be application of the paint with special capabilities.

Main Features

Long term usage

Corrosion resistant

Images

Specification

Base Material: HDGI ALUZINC CR

Grade: SGCC,DX51D,ASTMA653

Thickness: 0.3-0.8 TMT

Width 600-1450mm

Zinc Coating: 60-185g/m2

Paint: PE,PVDF,SMP,HDP

Coil ID:

508/610 recommend 508

Coil Weight: 4-8mt

T BENDING: 0-3T

PENCIL HARDNESS: ≥2H

IMPACT: ≥9J

MEK: ≥100

SALT SPRAY: ≥720hr

FAQ

Standard export packing, 4 eye bands and 4 circumferential bands in steel, galvanized metal fluted rings on inner and outer edges, galvanized metal and waterproof paper wall protection disk, galvanized metal and waterproof paper around circumference and bore protection

- Q:How are steel coils inspected for weldability using welding tests?

- A range of welding tests can be utilized to inspect steel coils for their weldability. The bend test is a common approach where a segment of the coil is cut and bent to assess the weld's quality. This evaluation helps identify any brittleness or flaws that could compromise its integrity. Furthermore, the guided bend test is conducted to evaluate the weld's ability to endure bending without cracking or breaking. Another technique employed is the macro etch test, which involves cutting a cross-section of the coil and applying a chemical solution to etch it. This test effectively exposes imperfections or irregularities in the weld, such as porosity, slag inclusions, or fusion deficiencies. Moreover, the hardness test measures the weld's hardness, which is crucial as excessive hardness can lead to cracking or brittleness, while insufficient hardness may cause weld failure under specific conditions. Additionally, non-destructive testing methods like ultrasonic testing, magnetic particle inspection, or radiographic examination can be employed to detect internal defects, such as cracks or voids, in the steel coil welds without causing any damage to the material. Conducting comprehensive inspections through these welding tests is essential to ensure the quality and weldability of steel coils before their use in various applications. By identifying and addressing potential issues, these inspections guarantee that the steel coils meet the necessary standards for weldability and structural integrity.

- Q:Hello people.Me and the life mate have been working on a fantasy book together and we are currently in the process of outlining the cultures. The culture of our antagonists' is a sort of woodland tribal/celtic[ish] deal and they are very nature oriented. Being a detail freak and wanting to have some real world credibility in the story, I am trying to decide how they produce steel. I want steel to be an important part of the culture, but a thing that is in limited supply. I also do not want there to be a large amount of resources committeded to mining or processing iron ore for steel. So does anyone have any real world ideas explaining how the people can produce steel without using underground mining operations, large processing facilities, and without raping the land?All help and ideas are appreciated

- Well, steel is just modified iron, so you're going to have to start with acquiring the iron first. For that, you're most likely going to be using some sort of underground mining somewhere - either they do that themselves, or they purchase the iron elsewhere. Assuming you're not dealing with meteoric iron (which is possible, but pretty uncommon), or iron sands (not likely in a woodland area), then unless you're dealing with a rocky outcropping with iron veins out in the open, I'm pretty sure there needs to be somebody doing some digging. That said, it doesn't need to be a full raping of the land scenario. A couple of minor mines, some small-scale smelting operations, and somebody knowing the secret of making steel, and it could give you small amounts of steel without making an ecological disaster.

- Q:How are steel coils processed and shaped into specific products?

- Steel coils are processed and shaped into specific products through a series of manufacturing steps. Initially, the coils are uncoiled and straightened to remove any bends or twists. Then, the steel is cut into desired lengths using shearing or slitting techniques. Next, the cut steel is shaped and formed through processes like rolling, bending, or stamping to achieve the desired shape. Additional operations such as welding, machining, or surface treatments may also be performed. Lastly, the finished products are inspected for quality and packaged for distribution.

- Q:How do steel coils contribute to energy performance in buildings?

- Steel coils can contribute to energy performance in buildings by providing insulation and thermal efficiency. The coils are often used in HVAC systems to enhance the heating and cooling processes, thus reducing energy consumption and improving overall energy efficiency. Additionally, steel coils can be used in roofing and cladding systems, providing insulation and helping to maintain a comfortable indoor temperature. By effectively managing heat transfer and reducing energy loss, steel coils play a crucial role in enhancing energy performance in buildings.

- Q:How are steel coils inspected for mechanical properties?

- Steel coils are inspected for mechanical properties through a series of tests and measurements. These include hardness testing, tensile testing, and elongation testing to determine the steel's strength, ductility, and overall quality. Additionally, non-destructive testing methods like ultrasonic testing and magnetic particle inspection are used to detect any potential defects or flaws in the coils. Overall, a combination of these inspection techniques ensures that steel coils meet the required mechanical properties for their intended applications.

- Q:In what ways can steel fail in use of buildings ad what can be done to prevent it?

- we fireproof steel in buildings now if thats what your talking about

- Q:What are the advantages of using steel coils?

- There are several advantages of using steel coils. Firstly, steel coils offer superior strength and durability, making them suitable for various applications in industries such as construction, automotive, and manufacturing. Secondly, steel coils have excellent resistance to corrosion, ensuring longevity and reducing maintenance costs. Additionally, steel coils can be easily shaped or formed into different sizes and shapes, providing flexibility in design and manufacturing processes. Lastly, steel coils are recyclable, making them an environmentally friendly choice and contributing to sustainable practices.

- Q:If needed for Defence could a stainless steel sword kill someone my buddy wanted this sword for Defece after it is sharpend here is a picture

- Ya it could kill someone if it was sharpened enough but from experience stainless steel swords don't get as sharp as Carbon or higher grade steel. Not to mention it would probably bend if you hit someone with it all the way. Hell the one I let some people who were chopping a bush ( just a normal bush ) they were playing around and it got bent. I'm going to say I can't suggest a stainless steel sword for anything other then handing on your wall. Not even going into the whole If you use a sword for self defense is it considered self defense? debate. It's a sketchy situation not to mention you would need training with a sword to actually use it without it just getting brushed off.

- Q:What could the impurities in steel wool be?And why are they there?Thanks for your help :)

- Impurities in steel wool would be of the elemental type. I'm sure steel wool is a mixture of different low grade not good for much of anything else materials. There may be excessive impurities such as lead, cobalt, boron, aluminum etc... in the steel wool. There may also be solvent residue on the wool i.e cleaner, lubricant etc.. I'm sure every batch is different - I know the iron level is high thats what makes them rust quickly.

- Q:What are the dimensions of steel coils used in the industrial machinery industry?

- The dimensions of steel coils used in the industrial machinery industry can vary depending on the specific application and requirements. However, generally speaking, steel coils used in this industry typically have a width ranging from 600 to 2,000 millimeters (24 to 79 inches) and a weight ranging from 2 to 25 metric tons (4,400 to 55,100 pounds). The inner diameter of the coil, known as the core, can range from 508 to 762 millimeters (20 to 30 inches). Additionally, the thickness of the steel coil can range from 0.4 to 25 millimeters (0.016 to 0.98 inches). These dimensions may be subject to variations based on the specific needs and specifications of the machinery being manufactured or used in the industrial machinery industry.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Printing Steel for Decoration JIS 3312 CGCC ASTM A653

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords