printing pvc celuka sheet/pvc foam core with die cutting

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

- Option:

- 1-30mm

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Introduction

PVC foam board is made from polyvinyl chloride, with flat plate surface; it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof, anticorrosive, metabolic and recyclable, moisture resistant, lightweight.

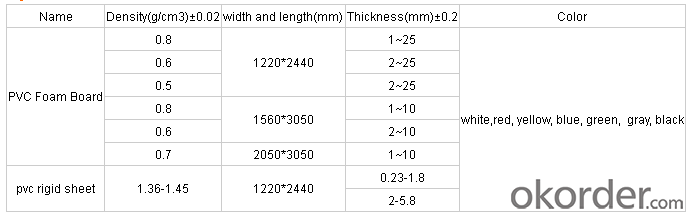

Product Specification

Regular size: 1220*2440mm, 1560*3050mm, 2050*3050mm

Thickness:1-33mm

Density:0.43- 0.9mm

Product Features

1.Waterproof, fireproof retardant, moistureproof, anticorrosive, Weather resistant, moth-proofing, anti cracking, anti UV.

2.Less warping, stand wear and tear, acid and alkali resistance, easy coloring, no glue and paint

3.Can be nailed, drilled, shaved, chiseled, riveted, With wood properties and better than wood, color diversity

4. Safety and environmental protection, formaldehyde-free

5. Easy to install, easy to clean, easy to maintain

Product Application

(1)Advertising: exhibition display, digital printing, silk screen printing, computer lettering, sign board, light box, etc.

(2)Construction: office and bathroom cabinets, inner and outer decorate panel, commercial decorating shelf, room separating

(3)Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layer and other industry.

Application fields | The specific application |

Household furniture | tables , chairs , benches , stools – furniture, Sofa, Box spring, Bookshelf, clothing case, tea table, screen, frame, handle, plate, bar, newspaper rack. |

Construction | Mobile home, window frame, door plank, threshold, template, concrete stairs clap, wallboard, ceiling, floor, and various profiles, etc |

Industrials | Chemical corrosion barrack and public places, decorating plate, floor, channel, bench, and the casting model, the machine cover, pump shell, electrical materials, etc |

........ | |

FAQ

3. Advantages of your products?

Answer :Company products, good quality, high reputation guarantee.

4. Are you a factory manufacturer or a trade company?

What are your product ranges? Where is your market?

Answer :we are manufacturer specializing in stationery and plastic packing products in highly quality and competitive price with over years,such as file folder,file bag,gift bag,closet organizer ,packages of cosmetic and other daily necessities, they are mainly famous ,such as USA, AUSTRILA, CANADA,EUROPE ,MIDDLE EAST,SOUTHEAST ASIA AND SO ON.

More Details of Product

- Q:Are plastic sheets resistant to solvents or oils?

- Yes, plastic sheets are generally resistant to solvents and oils.

- Q:What are the advantages of using plastic sheets?

- There are several advantages to using plastic sheets. Firstly, they are lightweight and easy to handle, making them convenient for various applications. Additionally, plastic sheets are highly durable and resistant to impact, moisture, and chemicals, making them suitable for both indoor and outdoor use. They also offer excellent thermal insulation properties, helping to maintain desired temperatures. Moreover, plastic sheets are cost-effective compared to other materials, making them a cost-efficient choice for construction and packaging industries. Lastly, plastic sheets can be easily molded and customized to fit specific shapes and sizes, providing versatility in design and functionality.

- Q:Wood chopping board, bamboo cutting boards, plastic boards, which is suitable for home?

- Now there are two kinds of boards, one is domestic, the most common is the Ironwood, now online there are a lot of people to buy, but although this material is hard, but most of them do not have professional treatment. Second kinds of European style boards, bamboo and some imported wood materials. Such as the European beech. Hard maple and American white oak, which belongs to high-grade mahogany, not only of hard wood, and these materials are dried and fumigated, basically there is no bacterial growth.

- Q:The letter viewed through the drop would be smaller than the others would because the drop acts as a concave lens.The letter viewed through the drop would be larger than the others would because the drop acts as a concave lens.The letter viewed through the drop would be smaller than the others would because the drop acts as a convex lens.The letter viewed through the drop would be larger than the others would because the drop acts as a convex lens.

- 4th one The drop forms a convex lens. The paper is inside the focal length of the lens so any image formed is upright, virtual and ...!!!! magnified !!!!... ;-)

- Q:Are plastic sheets resistant to cracking from impact?

- Yes, plastic sheets are generally resistant to cracking from impact.

- Q:Are plastic sheets resistant to abrasion?

- Yes, plastic sheets are generally resistant to abrasion.

- Q:What are the common uses of plastic sheets?

- Plastic sheets are commonly used for various purposes such as packaging materials, construction and building applications, signage, protective coverings, and even in the manufacturing of household items like shower curtains and storage containers.

- Q:Can plastic sheets be used for skirting boards or baseboards?

- Yes, plastic sheets can be used for skirting boards or baseboards. They are often used as an alternative to traditional wooden skirting boards due to their durability, moisture resistance, and ease of maintenance. Plastic sheets can be easily cut to size and installed, providing a clean and modern look to any space.

- Q:PC plastic PS plastic what is the difference between attention is the difference?! Come and answer

- PS is also called polystyrene,Born in 1930, it is a thermoplastic.

- Q:Some forums say it would be in Divisoria but I don't exactly know where it would be in that place. Any help would be greatly appreciated. Thanks.

- Buy Polypropylene

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

printing pvc celuka sheet/pvc foam core with die cutting

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

- Option:

- 1-30mm

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords