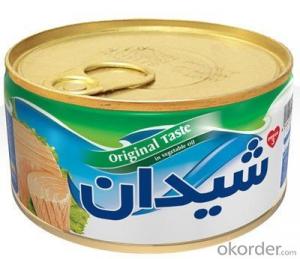

Printed Tinplate, EN 10202, Miscellaneous Can

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Usage

Tinplate is widely used for making all types of containers, containing industrial usage such as paint can, oil can, aerosol cans etc., and food cans like milk powder cans, tomato paste can, dry food cans etc.

2. Quality

As a state owned company and a large tinplate supplier in China, our tinplate quality ranks 1st level in China, similar to Bao Steel, Posco etc.

3. Specification

standard: GB/T2520, JIS G3303, DIN EN10202

Material: MR /SPCC

Thickness available: 0.16-0.50MM

Width available: 600~1050MM

Temper grade: T1 – DR8

Tin coating: ordinary 2.8g/2.8g, 5.6g/5.6g and others

Package: sea worthy export package.

Applications: Tin can for chemicals & paint cans, industrial cans, food cans

4. Our factory photo & equipments

5. Our Markets:

now our tinplate has been sold to more than 50 countries, including Europe country, Gulf Area, South American, South Afric etc.

6. Our Overseas Wareouses:

Furthermore, in the year 2014, we have more than 10 overseas warehouses all over the word, located in KSA, UAE, Oman, Russia, Kuwait, Qatar, Oman, Chile, Brazil etc.

7. FAQ

a. what's the annual output?

about 500,000 tons per year.

b. where's the raw matrial from?

our hot rolled coil is purchased from Capital Steel and other state owned mill, with quite good quality.

c. how long is the delivery time?

normally for SPCC about 45~55 days, while 65~75 days for MR material

d. how to control the quality during production process?

inside our workshop, we have MES syestem. It realizes the optimization of the production procedure in the workshop. It could record each step of the whole production procedures, and if some problem appears, factory could easily found and take action, it’s quite helpful to monitor and control the quality.

- Q:How does tinplate compare to plastic in terms of durability?

- Tinplate generally offers better durability compared to plastic. It is a sturdy material that can withstand external pressures and resist dents or breakage. Additionally, tinplate is less prone to cracking or warping over time, offering a longer lifespan for products made from it. On the other hand, plastic can be more prone to scratches, cracks, and degradation over time, making it less durable than tinplate.

- Q:What are the different ways to recycle tinplate containers?

- There are several different ways to recycle tinplate containers. One common method is to separate the tinplate from any other materials, such as plastic or paper, and then melt it down to create new tinplate products. Another option is to crush or shred the containers into small pieces, known as scrap, which can then be used as raw material for manufacturing new products. Additionally, recycling facilities may also use advanced technologies to separate the tinplate from any coatings or contaminants before recycling it.

- Q:How big is the difference between tinplate and stainless steel 316L?

- 316L is a kind of austenitic stainless steel with excellent corrosion resistance. The tinplate is not comparable. 316L is superior to tinplate in appearance, corrosion resistance, heat resistance and strength. Of course, the price is much higher than that of tinplate.

- Q:What are the common printing methods used on tinplate?

- The common printing methods used on tinplate include lithography, offset printing, and screen printing.

- Q:What are the main challenges in tinplate supply chain management?

- The main challenges in tinplate supply chain management include the volatility of raw material prices, ensuring consistent quality of tinplate products, managing global supply and demand fluctuations, optimizing transportation and logistics, and maintaining effective communication and collaboration among various stakeholders in the supply chain.

- Q:How does tinplate contribute to the presentation of jewelry?

- Tinplate contributes to the presentation of jewelry by providing a durable and attractive packaging solution. It offers a sleek and shiny surface that enhances the visual appeal of the jewelry, making it more eye-catching and appealing to customers. Additionally, tinplate's ability to be molded into various shapes and sizes allows for creative and customized packaging designs that can effectively showcase the jewelry's unique features. Its protective properties also help preserve the quality and condition of the jewelry, ensuring that it reaches the customers in pristine condition.

- Q:0.25mm which melting point is low in tin plate and tin plate?

- Tin plated steel sheet and strip, also known as tinplate, the steel plate (belt) surface tin plated, has good corrosion resistance, non-toxic, can be used as packaging material cans, inside and outside the cable sheath, telecommunications instrument parts, flashlight and other hardware.

- Q:Can tinplate be used for consumer electronics packaging?

- Yes, tinplate can be used for consumer electronics packaging. Tinplate is a durable and corrosion-resistant material that provides excellent protection for electronic devices. It is commonly used for packaging consumer electronics such as smartphones, tablets, and small appliances.

- Q:Can tinplate be used for packaging household products?

- Yes, tinplate can be used for packaging household products. Tinplate is a popular material choice for packaging due to its durability, versatility, and ability to protect products from moisture, light, and other external factors. It is commonly used for packaging food, beverages, and various household items such as cosmetics, cleaning products, and personal care products.

- Q:How does tinplate affect the environment?

- Tinplate can have both positive and negative impacts on the environment. On one hand, tinplate is a highly sustainable packaging material as it is 100% recyclable and can be reused multiple times without losing its properties. This helps in reducing waste and conserving resources. Additionally, tinplate containers offer excellent protection to the contents, preventing food spoilage and reducing the overall carbon footprint associated with food wastage. However, the production of tinplate involves mining and extracting tin, which can have adverse effects on the environment. Mining activities can lead to habitat destruction, soil erosion, and contamination of water sources if not properly managed. Furthermore, the manufacturing process of tinplate involves energy-intensive procedures, emitting greenhouse gases and contributing to climate change. To mitigate these negative impacts, it is crucial to promote responsible mining practices, prioritize energy-efficient manufacturing techniques, and encourage recycling and reuse of tinplate to minimize its environmental footprint.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Printed Tinplate, EN 10202, Miscellaneous Can

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords