Printed Plastic Biohazard Specimen Bag for Packaging

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of Printed Plastic Biohazard Specimen Bag for Packaging:

Printed Plastic Biohazard Specimen Bag for Packaging are processing with imported materials,we have introduced advanced equipment and high manufacturing technology into production lines and we have rich experience in producing plastic bag .can meet your needs by fulfilling your specification in a positive manner .High efficiency and speed are our working style .high quality and competitive price are our pursuit.

Printed Plastic Biohazard Specimen Bag for Packaging mainly used for packing in laboratory or medical field etc for biohazard using.

2. Main Features Printed Plastic Biohazard Specimen Bag for Packaging:

Good quality

Experienced manufacturer produced

Good for environment and good printing

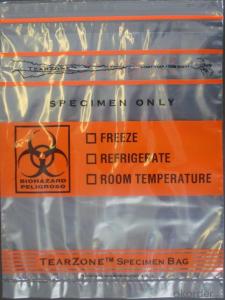

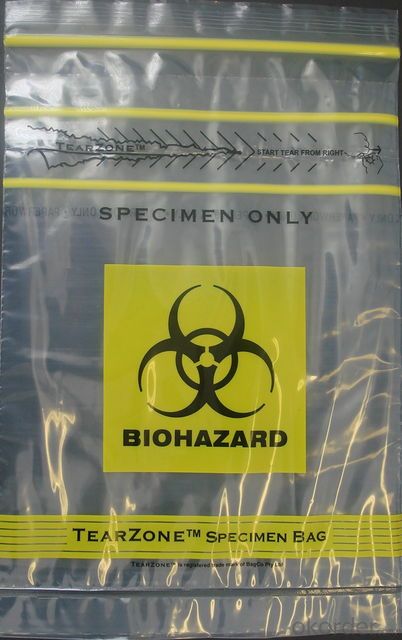

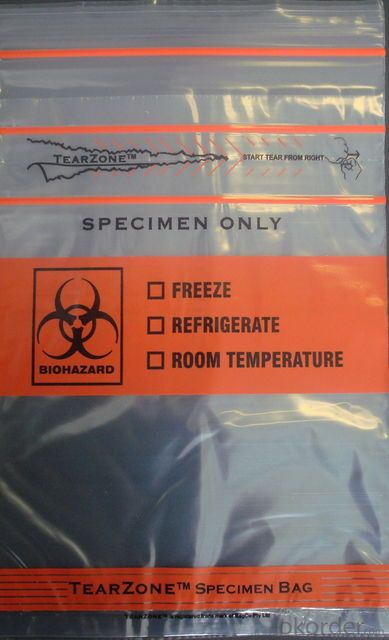

3. Printed Plastic Biohazard Specimen Bag for Packaging Photos:

4. Printed Plastic Biohazard Specimen Bag for Packaging Specification:

1. Material: PE or LDPE or HDPE or Lamiated

2.Size:5*1250px or Customized

3.Thickness:10-200micron

4.Production Flow:

Pre-press: Digital proof & rotogravure-cylinders production (engraving),

Rotogravure printing

Bag making

Quality checkingShipping

5.FAQ of Printed Plastic Biohazard Specimen Bag for Packaging:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Plastic packing bags can supply you all kind of packing bags you wanted.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q:What's the difference between plastic packaging bags and clothing bags?

- From film making, printing to bag making, there's a big difference. The clothes bag you say is just a bag of bags. There are several kinds of clothes bags I have used, and each machine needs different machines

- Q:Should the food packaging bags be labeled with QS markers?

- Forty-seventh of the 79 orders of the State Administration of food: forty-seventh the implementation of food quality and safety market access system, must print on their packages or marks before (paste) QS logo. No QS mark shall not be sold out of the factory.

- Q:What are the packaging forms of fresh milk?

- The main packaging forms of fresh milk are plastic bags, boxes and bottles. It is closely related to the way of sterilization of fresh milk

- Q:What kind of material is the express package on the market now? It's dark in the outer grey.

- It's a special packing bag for express delivery. That kind of paper bag, like post office, is specially designed to pack the things you want to express.Wrap things up and seal them in a bag.Some sellers or buyers need such bags when they are delivered. Some express to the seller to buy money.

- Q:Why are some teas not vacuum packed?

- Feng Xing packaging machinery factory experts explained that the main role of vacuum packaging machine is oxygen, moisture, high temperature fermentation, etc., in order to prevent the deterioration of tea. The principle is relatively simple, which is conducive to vacuum packaging machine to remove the air in the packaging bag, and then sealed, so that tea in a vacuum under the state, and absolutely isolated from the outside world.

- Q:What about the table of nutrition values on food packages?

- Total fatThis is in total fat as a unit, high fat food generally high calories. The lower the fat content, the healthier the food. As a rule, choose as much as 100 grams of food with less than 10 grams of fat. saturated fatSaturated fats are found in meats, poultry, fish, baked goods and tropical oils. They increase the risk of heart disease. Foods with the lowest levels of saturated fat should be selected. It should also be noted that in some food labels, trans fats - - for the heart, trans fats are more dangerous than saturated fats. Total CarbohydrateThis is the total number of carbohydrates per serving, in grams. It contains sugars and slow digestion carbohydrates. You may also see information about the glycemic index (GI). Compared with high GI foods, GI's blood sugar levels increase more slowly after lower food intake. sugarThese include natural sugars and added sugars, which are listed individually as part of the total carbohydrate component. In general, it is better to choose foods with lower sugar content. sodiumProcessed foods may have a large amount of sodium. If possible, choose foods with lower sodium content, that is, less than 400 milligrams per 100 grams of sodium. Other food information

- Q:What are the requirements of the gas in the package?

- The higher requirements are modified packaging: oxygen, nitrogen and carbon dioxide are used to fill the package in proportion to the product - respiration - use, to extend the shelf life of the product, and outside

- Q:Is the packet in the food package a reducing agent or an oxidizing agent?

- Take active ferric antioxidants as an example;Due to the activity of iron is extremely fine powder, high surface area, the rate of reaction with oxygen is faster. Reduced iron powder. In general, the reaction equation is 4Fe+3O2+6H2O=4Fe (OH) 3, and iron corrosion reactions may also occur.Followed by iron powder particles will adsorption of these smaller food packaging bags in water, the water, in part from within the food, in part from nature. After absorbing most of the excess water, the relative humidity in the food package can be kept constant, which plays a very important role in controlling microbial pollution.

- Q:Why is the higher the elevation, the more food bags inflate? From a physical point of view

- Because the food packaging bag is sealed, the air pressure inside is certain, with the elevation of the outside air pressure gradually decreased, which leads to gas bag outward extrusion pressure increased, so the higher the altitude, the food packaging bag inflated more.

- Q:What about the use of plastic bags?

- There are advantages and disadvantages. If it is a new material, the printing ink is also non-toxic. You can use it safely. If you use recycled materials, there is a foul smell. That's bad. What's more, we will bring plastic bags to the cooked food, it is best to buy from the supermarket, come back after the food will be taken out, to avoid food and plastic bags long-term exposure, chemical reaction products. That's bad for your health.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Printed Plastic Biohazard Specimen Bag for Packaging

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords