Print Prepainted Galvanized Steel Coil Marble Pattern

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Print Prepainted Galvanized Steel Coil Marble Pattern:

With GI as base metal,after pretreatmet (degrease and chemical treatment) and liquid dope with several Layers of color,then after firing and cooling,finally the plate steel is called pre-painted galvanized steel ( PPGI) .Pre-painted galvanized steel is good capable of decoration ,molding,corrosion resistance

2.Main Features of Print Prepainted Galvanized Steel Coil Marble Pattern:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

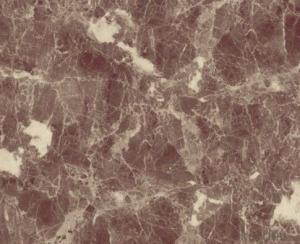

3.Print Prepainted Galvanized Steel Coil Marble Pattern Images

4.Print Prepainted Galvanized Steel Coil Marble Pattern Specification

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.13mm~3.0mm,

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

5.FAQ of Print Prepainted Galvanized Steel Coil Marble Pattern:

We have organized several common questions for our clients,may help you sincerely:

1.How do you control your quality

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2.How long we will receive the goods ?

After receiving your deposit or workable lc ,our normal shipment date is 15-20days,and it takes around 28 days to reach your port of destination. But is up to different destination

3. What is your MOQ?

Normally our MOQ is 25mt per size ,but it is up to different size.

- Q:What are the common thickness tolerances for steel coils?

- The common thickness tolerances for steel coils usually range from +/- 0.001 to +/- 0.005 inches, depending on the specific industry standards and customer requirements.

- Q:How do steel coil manufacturers ensure product quality?

- Steel coil manufacturers ensure product quality through a combination of rigorous quality control processes and adherence to industry standards. Firstly, they start by sourcing raw materials from trusted suppliers who provide high-quality steel. This ensures that the base material used for manufacturing the coils is of superior quality. Manufacturers also implement strict quality control measures during the production process. They employ advanced technologies and machinery to monitor various parameters such as thickness, width, and weight of the coils. This helps in maintaining consistency and accuracy in the dimensions and specifications of the products. To ensure the durability and strength of the steel coils, manufacturers subject them to various tests such as tensile strength testing, yield strength testing, and elongation testing. These tests help in determining the mechanical properties of the coils and ensure that they meet the required standards. In addition to these tests, manufacturers also conduct surface quality inspections to check for any defects or imperfections on the coils. They use techniques like visual inspection, ultrasonic testing, and magnetic particle inspection to identify any surface irregularities that may affect the quality of the product. Furthermore, steel coil manufacturers adhere to international quality standards such as ISO 9001, which ensures that their manufacturing processes are consistent and meet the required quality benchmarks. They also maintain regular communication and collaboration with customers to understand their specific requirements and incorporate any necessary changes to improve product quality. Overall, steel coil manufacturers prioritize product quality through a combination of stringent quality control measures, adherence to industry standards, and continuous improvement practices. This ensures that the steel coils they produce are of the highest quality and meet the expectations of their customers.

- Q:I should have known, but magnets don't stick to stainless steel, so now I'm at a loss, I can't display my photos on the fridge. any ideas?

- Hi There, I am re-doing my kitchen and since my all stainless steel refrigerator will no longer be used to hold all my memos and pictures, I will hang a magnetic board in one area of my kitchen which will hold all the photos and memos that I had before and it would look very neat this way.. bably much neater than when they were on the fridge. Also, you can get a multiphoto frame for the photos and hang this on the wall. Then, the magnetic board can be just for notes and clips with invitations, etc. Hope this helps.

- Q:I just got this aftermarket exhaust on my truck and it's recommended that it be welded, but the metal is aluminized steel. How do I mig weld aluminized steel?

- Yes. Buy a bimetallic strip where one edge is aluminum and the other is steel. A bimetallic strip is a special metal strip where an aluminum strip is fused to a steel strip by high frequency welding. You can form the strip to the shape of the table legs' cross section then weld the steel edge to the leg and the aluminum edge to the table top. Ensure however that the aluminum table top is a weldable alloy and compatible with the bimetallic strip.( You can not weld Al. Alloy 6061T6 so look for Al.Alloy 5086H32 or 5456H321 or the lower Al. Alloy designations, but they have to be strain hardened and not thermally hardened).

- Q:More specifically steel wire (around 1/8 diameter). I'm doing a science fair project where I'm testing if concrete encased in steel has more fire resistance than steel by itself. However, I have no idea what the dimensions of concrete encased steel is so I can't scale down. And if I did have the dimensions I wouldn't know how to encase it around the steel wire (do I just poor concrete over it (heck I've never even used concrete)? Thanks for any help.

- OK, here is my take on it Take equal lengths of steel wire, one is going to bare, one is going to be encased You will need a tension rig, simply this will be one fixed end and one end you can hang a weight down. For the test you will affix one end and string it between to supports with one end hanging off, which is where you will put the weight. The put a ruler where the weight is, so as the weight pulls the wire down (after it is hot) you can time the stretching. lastly you need a place to put a controlled fire under the wire, I'd reccommend something tame like a camping stove OK, got a test rig and two pieces and a way to test. You'll have to play with different fires and weights to see what works best Putting the concrete on the wire is a tricky one since you don't want the concrete to take the load. Get a tub or dish of approriate size and put some wet concrete in it, partway up. Take one of the wires and coat it with wax or something like it that is soft. Place the wire, with the ends sticking out, in the concrete tub and pour more on to cover it. Let this whole thing harden. You might want to have a specific shape to the tub so it comes out a certain size Now, you have an uncoated wire and an coated one. Be careful you don't pull the wire out of the concrete Another way to do this would be to use joing compound, which is a type of mortor (cement). You can buy it a home depot or such. Mix it up as thick as possible and just cake it on the wire and let harden. You can shape the coating using saran wrap or something maybe. I my world we call this stuff monster mud, its used to shape things for Halloween props like robes into figures. Its quite sturdy when done When you are ready to test just hook each part up with the same fire and weight and take readings of stretch vs. time

- Q:How are steel coils processed for cold rolling or hot rolling?

- Steel coils are processed for cold rolling or hot rolling through a series of steps. For cold rolling, the steel coils are first cleaned and pickled to remove any impurities. They are then passed through a series of rolling mills, where the steel is gradually reduced in thickness and elongated. This process improves the steel's strength and surface finish. In contrast, for hot rolling, the steel coils are heated to high temperatures and then passed through a series of rolling mills. The hot rolling process allows for greater deformability and shaping of the steel, resulting in different thicknesses and shapes.

- Q:What are the dimensions of steel coils used in the railway equipment industry?

- The railway equipment industry utilizes steel coils with dimensions that can vary according to the specific application and requirements. However, there are commonly observed dimensions for these steel coils, typically ranging from 3 to 5 feet in width and 10 to 15 feet in length. Likewise, the thickness of the steel coils exhibits variation, spanning from 0.01 to 0.5 inches. It should be noted that these dimensions are not set in stone and may fluctuate based on the specific demands of the railway equipment industry, such as the type of equipment being produced or the distinct purpose of the steel coils.

- Q:How do steel coil manufacturers meet customer specifications?

- Steel coil manufacturers meet customer specifications by following a comprehensive and systematic approach that involves various stages and processes. Here are some key steps they take: 1. Understanding customer requirements: Manufacturers initiate the process by thoroughly understanding the specific requirements of their customers. This includes determining the desired dimensions, tolerances, mechanical properties, surface finish, and any other specific characteristics needed. 2. Material selection: Based on the customer's requirements, manufacturers select the appropriate type and grade of steel to meet their specifications. This involves considering factors such as strength, corrosion resistance, formability, and cost-effectiveness. 3. Production planning: Manufacturers carefully plan their production processes to ensure that customer specifications are met. This involves determining the appropriate manufacturing techniques, equipment, and resources required. 4. Coil processing: Steel coils are processed through various stages such as hot rolling, cold rolling, annealing, pickling, and coating, depending on the customer's specifications. Each step is carefully controlled to achieve the desired properties and dimensions. 5. Quality control: Throughout the manufacturing process, strict quality control measures are implemented to ensure that the coils meet the customer's specifications. This includes regular inspections, testing, and compliance with industry standards. 6. Customization and flexibility: Steel coil manufacturers often offer customization options to meet specific customer needs. They have the capability to adjust the thickness, width, and length of the coils to match the desired specifications. 7. Communication and collaboration: Effective communication and collaboration between the manufacturer and the customer are crucial to meeting specifications. Manufacturers work closely with their customers to address any concerns or modifications required during the manufacturing process. 8. Documentation and certification: Once the steel coils are manufactured, manufacturers provide detailed documentation and certifications to ensure traceability and compliance with customer specifications. This includes providing test reports, material certificates, and any other necessary documentation. By following these steps, steel coil manufacturers can consistently meet customer specifications, ensuring that the final product meets the desired requirements and quality standards.

- Q:During fatigue testing of any material (especially for steels), why is strain-control mode preferred over stress control mode?

- because metals, like steel, are ductile and will stretch before breaking. Straining the metal is stretching it, stressing the metal is applying a shearing force or bending until there is an actual metal failure. A sheet metal strap 1inch across and 24 gauge metal is commonly used to support metal ducting systems in construction. These have an average strain to failure weight load as high as 16,200 lbs. As reported by the smacna index, they will safely hold 6800 pounds. Of more interest is the screws used to hold the strap to the duct. While they are grade 3, fairly strong, they strain to 1400 pounds when properly installed, and are safely able to support 650 pounds, unless they are overtorqued (stripped) and this quickly drops to 400 pounds and 125 pounds...big difference.

- Q:How are steel coils used in the manufacturing of springs?

- Steel coils are used in the manufacturing of springs by being formed into a helical shape, allowing them to store and release energy when subjected to force or pressure.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Print Prepainted Galvanized Steel Coil Marble Pattern

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords