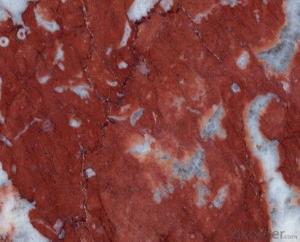

Print Prepainted Galvanized Steel Coil Big Marble Pattern

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Prepainted Galvanized Steel Coil:

With GI as base metal,after pretreatmet (degrease and chemical treatment) and liquid dope with several Layers of color,then after firing and cooling,finally the plate steel is called pre-painted galvanized steel ( PPGI) .Pre-painted galvanized steel is good capable of decoration ,molding,corrosion resistance

2.Main Features of Prepainted Galvanized steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Prepainted Galvanized steel Coil Images

4.Prepainted Galvanized steel Coil Specification

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.13mm~3.0mm,

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

5.FAQ of Prepainted Galvanized steel Coi

We have organized several common questions for our clients,may help you sincerely:

1.How do you control your quality

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2.How long we will receive the goods ?

After receiving your deposit or workable lc ,our normal shipment date is 15-20days,and it takes around 28 days to reach your port of destination. But is up to different destination

3. What is your MOQ?

Normally our MOQ is 25mt per size ,but it is up to different size.

- Q:Molton is formed at 2800 F. Thats a fact. Now jet fuel at its hottest is 1800. Where does the other 1000 degress come in? And it was found at the WTC 7 site. Was this hit by a plane? A simple fire COULD NOT produce molton. This is a fact. Molton is formed during controlled demoliton of a building since all the bombs in the buiding go off and its very very hot. The fact there was MOLTON at the site is shocking to some since it is IMPOSSIBLE for molton to form from jet feul alone. Impossible. It needed another source. Now the claim that I'll get is that it weakened the stell but then we would find weak steel not molton. Why do you seem to throw this off of your shoulder? Do you not want to belive it? I'm no jet fuel guy but I know you cannot make molton by using just jet fuel. This is really proof that 9/11 was an inside job.

- Aircraft frames are made out of aluminum and magnesium which burn very hot once they reach flame point. The other 1000 degrees can come from fire being in a a semi confined space, and heat building over time, plus you can reduce the heat if you add pressure which the building was under to start with. I did like a 2 year stint testing construction materials, I know a little bit about how they behave.

- Q:How are steel coils used in the production of industrial storage tanks?

- Industrial storage tanks commonly utilize steel coils due to their superior strength and durability. These coils are typically crafted from high-quality steel that is rolled into a coil shape, enabling convenient transportation and handling. During the production process, steel coils are initially uncoiled and flattened to create steel sheets. These sheets are then cut and formed into the desired shape and size for the storage tank. The steel sheets are joined together through welding or bolting to construct the tank's body, which is designed to endure high pressure and heavy loads. The utilization of steel coils in the production of industrial storage tanks offers numerous benefits. Firstly, the strength and durability of steel ensure that the tanks can withstand harsh conditions and resist corrosion. This is particularly vital for storage tanks containing corrosive substances or exposed to severe environments. Moreover, the flexibility of steel coils permits customization of the tank's design and size. This is especially advantageous in industries with varying storage requirements, like the oil and gas sector. Steel coils can be effortlessly cut and molded into diverse shapes and sizes, facilitating the creation of storage tanks tailored to specific storage needs. Furthermore, steel coils are easily transportable and storable, making them a cost-effective choice for industrial storage tank production. The coils can be efficiently transported to the manufacturing facility, reducing transportation costs and logistical complexities. In conclusion, steel coils play a crucial role in the production of industrial storage tanks by providing strength, durability, and customization options. Their usage guarantees the safe storage and protection of various substances, rendering them indispensable in a wide range of industries.

- Q:Explain why a steel nail sinks but a steel ship floats.

- Its all about dispersing.weigh and mass. Over a larger area .And the surface tention of the water.A piece of glass will float as long as the water is calm. and doesn't break over the edge of the glass. I don't remember the formula. been away from school to long.

- Q:For my homework we have to fill out a table, but I cannot find some basic uses of these types of steel anywhere:Low carbon steel (iron mixed with lt;0.25% carbon)High carbon steel (iron mixed with lt;1.5% carbon)Stainless steel (iron mixed with nickle an chromium)Titanium steel (iron mixed with titanium)Manganese steel (iron mixed with manganese) Thanks :)

- Low okorder / You say you cannot find there uses anywhere. These all came up using the simplest of web searches. You really need to have a word with your IT teacher as clearly you are not doing basic searches properly.

- Q:How are steel coils protected from humidity?

- Steel coils are typically protected from humidity through a process called galvanization, where a layer of zinc is applied to the surface of the steel. This zinc coating acts as a barrier, preventing moisture from coming into contact with the steel and causing corrosion. Additionally, the coils may be stored in a controlled environment with low humidity levels to further protect them.

- Q:Also, what is the top best slow cooker that is 100% stainless steel? Thank you!

- My SS pans are Prestige.

- Q:How are steel coils used in the production of metal storage systems?

- Steel coils are used in the production of metal storage systems as the primary raw material. These coils are processed and shaped into the desired forms, such as sheets, panels, or beams, which are then assembled to create sturdy and durable storage systems capable of safely storing various items.

- Q:aLSO, DOES STEEL C45 REFER TO THE CARBON IN IT?ALSO, WHAT IS AIRCRAFT GRADE PLYWOOD AND WHERE DOES ONE GET IT

- chromium nickle steel aka stainless steel exact amount of chrome and nickle will determine type/grade numbers Check the google for steel type/grade Never head of aircraft grade, however,, there is marine grade - normally baltic birch with waterproof glue and no defects i.e. knots, etc. Very strong (also quite expensive) but worth it for the correct applications

- Q:How are steel coils processed for specific applications?

- Steel coils are processed for specific applications through a series of carefully planned steps. The process begins with the selection of the appropriate grade and thickness of steel, which is determined based on the requirements of the end application. Once the steel coils are received, they undergo a series of processing steps to transform them into the desired product. The first step in processing steel coils is known as uncoiling, where the coil is unwound and straightened. This ensures that the coil is flat and ready for further processing. The uncoiled steel is then cleaned to remove any dirt, oil, or rust that may be present on the surface. This is typically done through a process called pickling, which involves immersing the steel in a bath of acid to remove any impurities. After cleaning, the steel undergoes various shaping processes depending on the desired application. This can include processes such as slitting, where the coil is cut into narrower strips, or shearing, where it is cut into specific lengths. These shaping processes are often performed using specialized machinery that can handle the high strength and thickness of steel. Once the steel has been shaped, it may undergo additional processes to enhance its properties. For example, it may be heat treated to increase its strength or hardness, or it may undergo a coating process to improve its corrosion resistance. Coating processes can include techniques such as galvanizing, where the steel is coated with a layer of zinc, or painting, where it is coated with a layer of paint. Finally, the processed steel coils are inspected for quality and undergo any necessary finishing processes. This can include processes such as trimming the edges to remove any irregularities, or applying protective coatings to prevent damage during transportation or storage. Overall, the processing of steel coils for specific applications is a complex and carefully controlled process. It involves a combination of shaping, cleaning, coating, and finishing processes to ensure that the steel meets the required specifications and is ready for use in various industries such as automotive, construction, and manufacturing.

- Q:I know that steel wool is coated with... something... that protects it from rusting. I need to know what that is, and how to get it off.

- spun steel fibers have a microscopic coating of oil to prevent them from rusting. Rusting steel wool wouldn't sell very well. I would think that removing this oil could be accomplished with any good degreaser, like brake cleaner or the like. However, I've never tried this before. In science class they perform experiments by removing the oil with vinegar. After wringing out the steel wool pad, it is wrapped around a thermometer and placed in a sealed jar. After a few minutes the temperature rises because of the chemical reaction that takes place when four atoms of iron react with three atoms of oxygen and create two atoms of iron oxide - RUST! You can unwittingly recreate this experiment by using steel wool in the process of removing one or more layers of finish from a piece of furniture Hope this helps

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Print Prepainted Galvanized Steel Coil Big Marble Pattern

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords