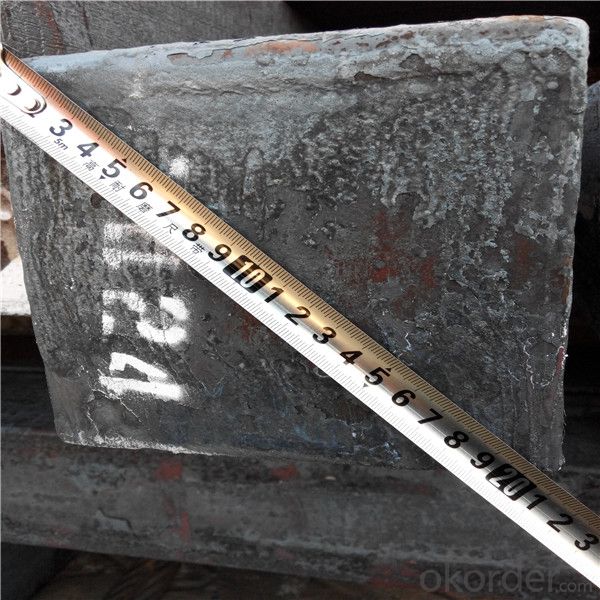

Prime square steel billet best price from China

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 14721 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

Steel billets have distinct characteristics as compared with already furnished steel bars and products.

Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets

are also known for their malleability and ductility, especially when exposed to varying temperatures during

shaping and molding.

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Other Specifications

Squar Tolerance: ±4

Length Tolerance: +100mm

Romboidity/Difference Diagonals: no more than 0.7%

Camber: no more than 1.5%(%)

Twist: no more than 3 degrees per 1 meter length

Our Advantage

* Professional Personnel of Steel Trading

* Strong Steel Industry Background

* Conveniently Geographic Location

Our Commitment

* Sincere, Practical, Efficient and Developing

* High Quality Steel Production

* Competitive Price and Timely Delivery

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: How to get quotation?

A: When we receive your detailed enquiry, we will set the best price based on standard,

steel grade, outer diameter, wall thickness, quantity, country.

And we will send quotation to your mailbox.

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q:Can steel billets be used in the automotive industry?

- Yes, steel billets can be used in the automotive industry. They are commonly used as raw materials for manufacturing various automotive components such as engine blocks, transmission gears, axles, and suspension parts. The high strength and durability of steel make it an ideal choice for ensuring the safety and performance of vehicles.

- Q:How are steel billets priced in the market?

- Steel billets are typically priced in the market based on various factors such as supply and demand dynamics, production costs, and market conditions. The pricing is influenced by factors such as raw material costs, energy prices, transportation costs, and any applicable taxes or duties. Additionally, market participants consider factors like global economic trends, industry forecasts, and geopolitical events that may impact the overall steel market. Ultimately, steel billet pricing is determined through negotiations between buyers and sellers based on these various factors.

- Q:How do steel billets contribute to the overall fire resistance of a structure?

- Steel billets do not directly contribute to the fire resistance of a structure. However, steel is a fire-resistant material and when used in the construction of a building, it can enhance the overall fire resistance by providing structural integrity and stability even at high temperatures.

- Q:What industries rely heavily on steel billets?

- Several industries heavily rely on steel billets as a crucial raw material for their manufacturing processes. One such industry is the construction industry, which uses steel billets to fabricate structural components such as beams, columns, and reinforcement bars. Steel billets provide the required strength and durability necessary for constructing buildings, bridges, and other infrastructure projects. The automotive industry also heavily relies on steel billets. Steel billets are used to manufacture various automotive parts, including engine components, chassis, and suspension systems. The high strength and versatility of steel billets make them ideal for producing parts that can withstand rigorous conditions and ensure vehicle safety. In addition, the oil and gas industry heavily depends on steel billets for the production of pipelines, drill pipes, and other equipment used in exploration, extraction, and transportation processes. Steel billets are preferred due to their corrosion resistance, high pressure resistance, and ability to withstand extreme temperatures. Moreover, the machinery and equipment manufacturing industry extensively uses steel billets as a primary material for producing a wide range of machinery, including industrial machinery, agricultural equipment, and heavy-duty machinery. Steel billets provide the necessary strength, toughness, and machinability required for these applications. Furthermore, the aerospace industry relies on steel billets for manufacturing various aircraft components, such as landing gear, structural frames, and engine parts. Steel billets are chosen for their high strength-to-weight ratio, heat resistance, and ability to withstand the demanding conditions of aerospace applications. Overall, steel billets play a vital role in several industries, including construction, automotive, oil and gas, machinery and equipment manufacturing, and aerospace. The unique properties of steel billets make them indispensable in these industries, ensuring the production of strong, durable, and reliable products.

- Q:What are the different international standards for steel billets?

- There are several international standards for steel billets, which are used as raw material for the production of various steel products. Some of the prominent international standards for steel billets include: 1. ASTM A615/A615M: This standard provides specifications for deformed carbon-steel bars for concrete reinforcement. It includes requirements for billets used in the manufacturing of these bars. 2. EN 10025: This European standard specifies the technical delivery conditions for structural steel products. It covers a wide range of steel grades, including billets, used in construction and engineering applications. 3. JIS G3112: This Japanese Industrial Standard defines the requirements for steel bars, including billets, used for concrete reinforcement. It ensures the quality and performance of steel billets in the construction industry. 4. GB/T 699: This Chinese standard sets out the technical requirements for quality carbon structural steel, including billets. It covers aspects related to chemical composition, mechanical properties, and heat treatment. 5. IS 2830: This Indian Standard outlines the specifications for carbon steel billets for general engineering purposes. It includes requirements for chemical composition, mechanical properties, and dimensional tolerances. These international standards ensure the consistency, quality, and safety of steel billets used in various industries globally. Adherence to these standards helps to maintain uniformity and facilitates the global trade of steel products.

- Q:How are steel billets manipulated during the manufacturing process?

- Steel billets are manipulated in various ways during the manufacturing process to transform them into usable steel products. The manipulation techniques include heating, rolling, forging, and cutting. Firstly, the steel billets are heated in a furnace to a specific temperature, known as a rolling temperature. This heating process is crucial as it improves the billet's malleability and reduces its brittleness, making it easier to manipulate. Once heated, the billets are passed through a series of rolling mills. These mills apply pressure to the billets, which elongates and shapes them into the desired form. Rolling can be done using hot or cold methods, depending on the end product requirements. Hot rolling is typically used for large-scale production, while cold rolling is more commonly employed for precision applications. Another method of manipulating steel billets is forging. Forging involves applying compressive forces to the billets using hammers or presses. This process enhances the billet's strength, improves its grain structure, and refines its mechanical properties. Forged steel billets are often used in applications where high strength and resistance to impact and fatigue are required, such as in the automotive and aerospace industries. Cutting is also an essential manipulation technique during the manufacturing process. Steel billets are cut into desired lengths using saws or shears. This step ensures that the billets are converted into manageable sizes suitable for further processing or to meet specific customer requirements. In conclusion, steel billets undergo several manipulation techniques during the manufacturing process. These include heating, rolling, forging, and cutting. Each method contributes to transforming the raw billets into the desired shape and properties, ensuring they are suitable for various applications in industries such as construction, manufacturing, and transportation.

- Q:How do steel billets contribute to the manufacturing of water and wastewater treatment equipment?

- Steel billets play a crucial role in the manufacturing of water and wastewater treatment equipment. These billets are essentially semi-finished steel products that are used as raw materials for various industrial applications. When it comes to the water and wastewater treatment industry, steel billets are utilized in the production of key components such as tanks, pipes, valves, and pumps. One of the primary reasons steel billets are favored in this industry is due to their excellent strength and durability. Water and wastewater treatment equipment are subjected to harsh operating conditions, including exposure to corrosive chemicals, high pressure, and extreme temperatures. Steel billets, made from high-quality materials such as carbon steel or stainless steel, offer the necessary strength and resistance to withstand these demanding environments. Furthermore, steel billets can be easily fabricated and formed into different shapes and sizes, making them highly versatile for manufacturing water and wastewater treatment equipment. These billets can be forged, rolled, or extruded to create components with precise specifications, ensuring a perfect fit and optimal functionality. The corrosion resistance of stainless steel billets is particularly valuable in water and wastewater treatment equipment. These billets are highly resistant to rust and corrosion, preventing contamination of the water supply and ensuring the longevity of the equipment. Stainless steel billets are also hygienic, making them suitable for applications where maintaining water quality and cleanliness is of utmost importance. Additionally, steel billets offer cost-effectiveness in the manufacturing process. The abundance of steel as a material and its recyclability make it a cost-efficient choice for producing water and wastewater treatment equipment. The long lifespan of steel components also reduces the need for frequent replacements, resulting in lower maintenance and operational costs. In summary, steel billets are essential in the manufacturing of water and wastewater treatment equipment due to their strength, durability, versatility, corrosion resistance, and cost-effectiveness. These billets provide the necessary raw materials to create robust and reliable components that can withstand the challenging conditions of the water treatment industry.

- Q:How are steel billets cut into smaller pieces?

- Steel billets are typically cut into smaller pieces through a process called sawing or shearing. There are various methods used to achieve this, depending on the desired size and precision of the cuts. One common method is using a saw blade, either circular or band saws, which are specifically designed for cutting through metal. These saws can be manually operated or automated, depending on the scale of the operation. The billets are clamped securely to prevent movement, and the saw blade is guided along the marked cutting line, gradually slicing through the steel to create smaller pieces. Another approach is shearing, which involves using a shear machine to apply intense force to cut through the billet. This method is often used for thicker billets or when precise cuts are not necessary. The shear machine consists of a fixed blade and a moving blade that come together to sever the billet along the desired cutting line. Additionally, advanced technologies like laser cutting or plasma cutting can also be employed to cut steel billets into smaller pieces. These methods utilize high-powered lasers or plasma jets to melt or vaporize the material along the cutting line, resulting in a clean and precise cut. Overall, the choice of cutting method depends on factors such as the thickness of the billet, the desired precision of the cuts, and the production capacity. Regardless of the method used, safety precautions are always taken to ensure the well-being of the operators and to maintain the quality of the cut steel pieces.

- Q:What are the different types of steel alloys used for manufacturing steel billets?

- There are various types of steel alloys used for manufacturing steel billets, including carbon steel, alloy steel, and stainless steel. Carbon steel is the most commonly used alloy and is known for its strength and durability. Alloy steel contains additional elements such as nickel, chromium, or manganese, which enhance its properties and make it suitable for specific applications. Stainless steel, on the other hand, is corrosion-resistant and often used in industries requiring high resistance to rust and staining.

- Q:How do steel billets contribute to the manufacturing of electrical appliances?

- Steel billets play a vital role in the manufacturing of electrical appliances by providing a strong and durable material for various components. Electrical appliances, such as refrigerators, washing machines, and air conditioners, require sturdy structures to withstand constant usage and external forces. Steel billets, which are semi-finished metal products, are used as a raw material in the manufacturing process to create these robust structures. Firstly, steel billets are forged or rolled into different shapes and sizes to create the frames, chassis, and housing of electrical appliances. These components provide the necessary support and protection for the internal parts of the appliances. The strength and stability of steel make it an ideal choice for withstanding the weight and vibrations generated during the operation of electrical appliances. Additionally, steel billets are used to fabricate the motor cores and transformer cores in electrical appliances. Motor cores are essential for converting electrical energy into mechanical energy, while transformer cores are responsible for regulating the voltage in electrical circuits. Steel's magnetic properties, such as high electrical conductivity and low hysteresis loss, make it an excellent choice for these applications, ensuring efficient energy conversion and transmission. Moreover, steel billets are utilized to manufacture heating elements and electrical contacts in appliances like stoves, ovens, and switches. These components require materials that can withstand high temperatures, resist corrosion, and provide excellent electrical conductivity. Steel billets are often alloyed with other metals, such as nickel or chromium, to enhance these properties, making them highly suitable for such applications. In conclusion, steel billets contribute significantly to the manufacturing of electrical appliances by providing a durable and versatile material for various components. The strength, stability, and magnetic properties of steel make it an essential raw material for creating the frames, motor cores, transformer cores, heating elements, and electrical contacts used in these appliances. Thanks to steel billets, electrical appliances can perform reliably and efficiently, meeting the needs and expectations of consumers.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Prime square steel billet best price from China

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 14721 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords