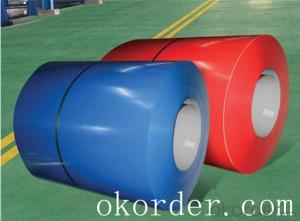

Prime quality prepainted galvanized steel 630mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Construction building material galvanized color prepainted cold

rolled steel coil

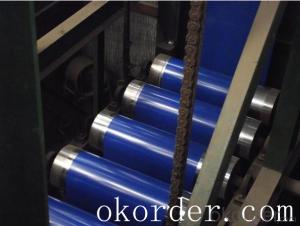

Prepainted steel sheet is coated with organic layer, which provides higher anti-corrosion property and

a longer lifespan than that of galvanized steel sheets.

The base metals for prepainted steel sheet consist of cold-rolled, HDG electro-galvanized and hot-dip

Alu-zinc coated. The finish coats of prepainted steel sheets can be classified into groups as follows:

polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc

Standard and Grade :

Pre-paint galvanized steel coil | ||||

ASTM A755M-03 | EN10169:2006 | JISG 3312-2012 | ||

Commercial quality | CS | DX51D+Z | CGCC | |

Structure steel | SS GRADE 230 | S220GD+Z | CGC340 | |

SS GRADE 255 | S250GD+Z | CGC400 | ||

SS GRADE 275 | S280GD+Z | CGC440 | ||

SS GRADE 340 | S320GD+Z | CGC490 | ||

SS GRADE550 | S350GD+Z | CGC570 | ||

S550GD+Z | ||||

Application:

Outdoor | Roof, roof structure, surface sheet of balcony, frame of window, door of garage, rolled shutter door, booth, Persian blinds, cabana, etc |

Indoor | Door, isolater, frame of door, light steel structure of house, home electronic appliances, ect. |

- Q:What is the role of steel billets in the construction of high-rise buildings?

- Steel billets play a vital role in the construction of tall buildings, serving as the raw material for structural components like beams, columns, and girders. Their exceptional strength and durability make them ideal for supporting heavy loads and resisting external forces such as wind and earthquakes. Furthermore, steel billets offer design and construction flexibility, allowing architects and engineers to create intricate and visually appealing structures. Their versatility also enables the construction of large spans, reducing the need for excessive supporting columns and maximizing usable space. In addition, steel billets are highly resistant to corrosion and fire, ensuring the longevity and safety of skyscrapers. The galvanized or coated surface protects against rust, while the fire-resistant properties of steel maintain its strength at high temperatures. Moreover, steel billets contribute to the sustainability and environmental efficiency of high-rise construction. The use of recycled steel billets reduces the demand for virgin resources and minimizes waste, aligning with sustainable development principles. In conclusion, steel billets are crucial for constructing tall buildings due to their strength, durability, flexibility, resistance to corrosion and fire, and contribution to sustainable development. They enable the creation of robust, safe, and aesthetically pleasing structures that can withstand various forces and optimize space utilization.

- Q:What are the potential applications of steel billets in the food and beverage aftermarket?

- Steel billets have limited applications in the food and beverage aftermarket due to their inherent properties and composition. However, they can be used in certain non-direct contact applications such as equipment fabrication, machinery parts, or structural components in food processing facilities. These billets can provide strength, durability, and stability, contributing to the overall infrastructure and functionality of the food and beverage industry.

- Q:What are the main challenges in sourcing steel billets?

- The main challenges in sourcing steel billets include fluctuating prices, ensuring quality standards, finding reliable suppliers, dealing with logistics and transportation, and managing the risks associated with international trade and political instability in some steel-producing regions.

- Q:What are the different types of steel billet welding processes?

- Various industries commonly use several different types of steel billet welding processes. These processes include the following: 1. SMAW (Shielded Metal Arc Welding), also known as stick welding, utilizes a flux-coated electrode that is manually fed into the welding pool. It is a versatile and widely employed method for welding steel billets. 2. GMAW (Gas Metal Arc Welding), commonly referred to as MIG welding, involves a continuously fed wire electrode and a shielding gas to protect the weld pool. Due to its efficiency and ease of use, it is a popular choice for welding steel billets. 3. FCAW (Flux-Cored Arc Welding) is similar to GMAW, but instead of a solid wire, it uses a tubular electrode filled with flux. This process is often favored for outdoor or windy conditions due to the flux's superior protection against atmospheric contamination. 4. SAW (Submerged Arc Welding) entails feeding a consumable electrode and a granular flux into the weld zone, while the arc remains submerged beneath a layer of flux. It is commonly applied for welding large steel billets because of its high deposition rates and deep penetration capabilities. 5. GTAW (Gas Tungsten Arc Welding), also known as TIG welding, utilizes a non-consumable tungsten electrode and a shielding gas to safeguard the weld pool. This precise and high-quality welding process is suitable for thin steel billets or applications that require exceptional weld aesthetics. 6. ESW (Electroslag Welding) is a highly efficient process employed for welding thick steel billets. It involves melting a consumable electrode and the base metal in a molten slag pool, which provides protection and acts as a filler material. 7. LBW (Laser Beam Welding) utilizes a high-energy laser beam to melt and join steel billets together. It is a precise and fast welding process commonly used in industries such as automotive and aerospace. Each of these welding processes has its own advantages and limitations. The choice of process depends on factors such as the type and thickness of the steel billet, desired weld quality, production requirements, and cost considerations.

- Q:Are steel billets subject to any regulations or certifications?

- Steel billets must adhere to numerous regulations and certifications to guarantee their production, quality, and safety standards are met. The ISO 9001 certification, an internationally recognized standard for quality management systems, is one of the most common certifications for steel billets. This certification ensures that the manufacturing process of steel billets follows consistent quality control measures, from sourcing raw materials to final production. Steel billets may also need to obtain industry-specific certifications, depending on their intended use. For example, if the steel billets are intended for construction projects, they must comply with certifications such as ASTM standards or European EN standards. These certifications define the necessary mechanical properties, chemical composition, and other specifications that steel billets must meet to ensure they are suitable for construction purposes. In addition, governmental bodies or industry associations may impose regulations on steel billets. These regulations can include safety standards, environmental regulations, and compliance with trade policies. For instance, steel billet producers may need to comply with regulations regarding emissions, waste management, or occupational health and safety. In conclusion, various regulations and certifications are in place to ensure the quality, safety, and compliance with industry standards of steel billets. These certifications and regulations are crucial for maintaining the integrity of steel billets and ensuring they are suitable for various applications.

- Q:What is the average cost of steel billets?

- Several factors can influence the average cost of steel billets, including the type of steel, market conditions, and global supply and demand. Steel billets are semi-finished metal products commonly used as raw materials for various steel products. As of September 2021, the average price of steel billets ranges from $400 to $600 per metric ton. However, it is important to be aware that this price can fluctuate significantly due to factors such as changes in raw material costs (such as iron ore and scrap metal), energy prices, transportation costs, and market dynamics. Furthermore, specific countries or regions may experience variations in the average cost of steel billets due to regional factors like import tariffs, trade restrictions, and currency exchange rates. It is always recommended to seek advice from industry experts, steel suppliers, or consult market reports for the most accurate and up-to-date information on the current average cost of steel billets.

- Q:Can steel billets be used for making decorative items?

- Yes, steel billets can be used for making decorative items. Steel billets can be shaped, molded, and crafted into various designs and forms to create decorative items such as sculptures, furniture, artwork, and architectural features. The strength and durability of steel make it suitable for these purposes while adding a modern and industrial aesthetic to the decorative pieces.

- Q:What is the process of hot rolling steel billets?

- The process of hot rolling steel billets involves several steps to transform the billets into a desired shape and size. Firstly, steel billets, which are semi-finished products made from molten steel that has been cast into rectangular or square shapes, are heated to high temperatures in a reheating furnace. This heating process helps to make the steel more malleable and easier to shape. Once the billets reach the required temperature, they are fed into a series of rolling mills. These mills consist of a series of rotating rolls that exert pressure on the billets, gradually reducing their thickness and shaping them into long, flat, or shaped steel products. The number of rolling mills used in the process depends on the desired final product. As the billets pass through the rolling mills, they undergo multiple passes to achieve the desired shape and size. The rolls in each pass apply pressure on the billets, causing them to elongate and reduce in thickness. In some cases, the billets may also be twisted or bent to achieve specific shapes or profiles. During the rolling process, the steel billets are constantly monitored for temperature, dimensions, and surface defects. Any imperfections or irregularities detected are rectified through various corrective measures, such as adjusting the rolling parameters or using specialized equipment. After the desired shape and dimensions are achieved, the hot-rolled steel products are cooled by either air or water to prevent them from warping or losing their structural integrity. This cooling process, known as quenching, also helps in achieving the required mechanical properties of the steel. Finally, the hot-rolled steel products are cut into desired lengths and may undergo additional treatments, such as straightening or surface finishing, to meet specific customer requirements. The finished hot-rolled steel products are then ready for further processing, such as welding, fabrication, or assembly, depending on their intended use in various industries such as construction, automotive, or manufacturing.

- Q:What are the different types of steel billet quality control tests?

- To ensure the integrity and suitability of steel billets for further processing, various types of quality control tests are conducted. These tests play a vital role in maintaining the desired quality standards in the steel industry and detecting any defects or inconsistencies in the billets. Some commonly used tests for steel billet quality control are as follows: 1. Visual Inspection: This test involves visually examining the billets to identify surface defects like cracks, seams, or dents. It is a fundamental form of quality control and can be carried out quickly. 2. Dimensional Inspection: In this test, the dimensions of the billets are measured and compared to specified tolerances. This ensures that the billets fall within the required size range and meet the dimensional requirements for further processing. 3. Chemical Composition Analysis: This test involves analyzing the chemical composition of the steel billets to ensure they meet the specified requirements. It includes determining the percentages of different elements such as carbon, manganese, sulfur, and phosphorus. 4. Mechanical Testing: This test evaluates the mechanical properties of the steel billets, such as tensile strength, yield strength, and elongation. These properties are crucial in determining the billets' suitability for specific applications. 5. Ultrasonic Testing: This non-destructive testing method utilizes ultrasonic waves to detect internal defects like cracks or voids in the billets. It is particularly effective in identifying hidden defects that may not be visible during visual inspection. 6. Magnetic Particle Inspection: This test involves applying a magnetic field to the billets and then introducing magnetic particles to the surface. Any surface or near-surface defects will cause the particles to gather, indicating the presence of a defect. 7. Eddy Current Testing: This method uses electromagnetic induction to detect surface defects or variations in the billets' electrical conductivity. It is useful in identifying cracks, voids, or inconsistencies in the billets' microstructure. 8. Microstructure Analysis: This test involves examining the microstructure of the steel billets under a microscope to assess homogeneity, grain size, and the presence of any undesirable phases. It aids in determining the overall quality and suitability of the billets for further processing. These tests, alongside other specific tests, are an integral part of steel billet quality control. By conducting these tests, manufacturers can ensure that the billets meet the required standards and possess the necessary properties for their intended applications.

- Q:What are the main factors that determine the demand for steel billets in different industries?

- The main factors that determine the demand for steel billets in different industries are the overall economic conditions, including GDP growth and industrial production, as well as the specific needs and requirements of each industry. Other factors include the level of infrastructure development, population growth, urbanization, and construction activities. Additionally, factors such as technological advancements, environmental regulations, and government policies can also influence the demand for steel billets in different industries.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Prime quality prepainted galvanized steel 630mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords