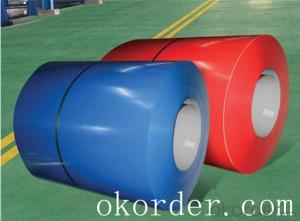

Prime quality prepainted galvanized steel 625mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Construction building material galvanized color prepainted cold

rolled steel coil

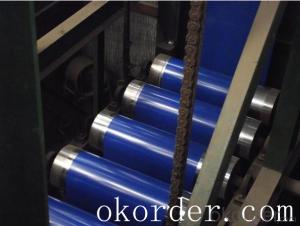

Prepainted steel sheet is coated with organic layer, which provides higher anti-corrosion property and

a longer lifespan than that of galvanized steel sheets.

The base metals for prepainted steel sheet consist of cold-rolled, HDG electro-galvanized and hot-dip

Alu-zinc coated. The finish coats of prepainted steel sheets can be classified into groups as follows:

polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc

Standard and Grade :

Pre-paint galvanized steel coil | ||||

ASTM A755M-03 | EN10169:2006 | JISG 3312-2012 | ||

Commercial quality | CS | DX51D+Z | CGCC | |

Structure steel | SS GRADE 230 | S220GD+Z | CGC340 | |

SS GRADE 255 | S250GD+Z | CGC400 | ||

SS GRADE 275 | S280GD+Z | CGC440 | ||

SS GRADE 340 | S320GD+Z | CGC490 | ||

SS GRADE550 | S350GD+Z | CGC570 | ||

S550GD+Z | ||||

Application:

Outdoor | Roof, roof structure, surface sheet of balcony, frame of window, door of garage, rolled shutter door, booth, Persian blinds, cabana, etc |

Indoor | Door, isolater, frame of door, light steel structure of house, home electronic appliances, ect. |

- Q:What are the specifications for stainless steel billets used in the food industry?

- To ensure safety and hygiene, the food industry requires stainless steel billets to meet specific specifications. These specifications focus on the stainless steel's composition, corrosion resistance, and ability to withstand high temperatures and aggressive cleaning agents. First and foremost, stainless steel used for food industry billets must contain a high percentage of chromium, typically ranging from 16% to 18%. This high chromium content ensures excellent corrosion resistance, preventing any reaction with food or cleaning agents. In addition, these billets should have a low carbon content, usually below 0.08%. By keeping the carbon content low, the stainless steel becomes less susceptible to sensitization, which can cause corrosion and contamination of food products. Furthermore, the stainless steel billets must adhere to specific international standards, such as ASTM A276 or EN 10088. These standards outline the minimum requirements for chemical composition, mechanical properties, and surface finish. Moreover, the surface finish of the billets is crucial in the food industry. It must be smooth and free from defects like pits or cracks to prevent the accumulation of bacteria and facilitate easy cleaning. The dimensions of the billets also contribute to their suitability for the food industry. They are commonly available in square or rectangular shapes, with various sizes depending on the specific application. Lastly, these billets should be certified and compliant with industry regulations, such as those set by the Food and Drug Administration (FDA) or the European Food Safety Authority (EFSA). In conclusion, stainless steel billets used in the food industry must meet specific requirements regarding chromium and carbon content, international standards, surface finish, dimensions, and industry regulations for safety and hygiene.

- Q:What are the main factors that affect the availability of steel billets?

- The main factors that affect the availability of steel billets include the demand and consumption patterns in the steel industry, the production capacity and efficiency of steel mills, fluctuations in raw material prices, government policies and regulations, and global economic conditions.

- Q:What is the role of steel billets in the construction of power plants?

- The construction of power plants relies heavily on steel billets, which are semi-finished steel products utilized as raw materials in various processes involved in power plant production. A significant application of steel billets in this field is the creation of structural steel, which forms the framework of power plant structures like the main building, turbine halls, reactor buildings, and cooling towers. To produce the necessary structural components such as beams, columns, and trusses, steel billets are melted, refined, and cast into different shapes and sizes. These components provide essential support and stability to power plant infrastructure. Furthermore, steel billets are crucial in the manufacturing of equipment and machinery necessary for power generation. Turbine rotors, generator frames, and condensers are among the components produced using steel billets. These components play a vital role in the operation of power plants and contribute to efficient energy conversion. Moreover, steel billets are utilized in the construction of storage tanks, pipelines, and ducts within power plants. These structures are crucial for storing and transporting various fluids like water, steam, and fuel. Steel billets are transformed into sheets, plates, and tubes to fabricate these components, which are designed to withstand high pressures and temperatures. Steel billets are also highly durable and possess exceptional mechanical properties such as strength and toughness. These properties enable them to withstand the harsh operating conditions and loads experienced in power plants. They can endure high temperatures, corrosion, and stresses, ensuring the structural integrity and longevity of power plant infrastructure. In conclusion, steel billets are indispensable in power plant construction as they are employed in the production of structural components, equipment, and machinery. Their durability, strength, and versatility make them the preferred material in this industry. The use of steel billets guarantees the reliability and safety of power plants, ultimately contributing to the generation of electricity for various industries and communities.

- Q:What are the common surface defects found in steel billets?

- Some common surface defects found in steel billets are scale, cracks, laps, seams, and surface decarburization.

- Q:What are the main challenges in the storage of steel billets?

- The main challenges in the storage of steel billets include maintaining proper environmental conditions, managing space efficiently, ensuring safety measures, preventing corrosion, and minimizing material damage. Firstly, the storage area should be maintained at a controlled temperature and humidity to prevent the steel billets from being exposed to extreme weather conditions, which could lead to rusting, oxidation, or other forms of corrosion. Adequate ventilation is also necessary to prevent the buildup of moisture that could affect the quality of the billets. Secondly, managing space efficiently is crucial in steel billet storage. Billets are often stored in large quantities, so proper organization and stacking methods must be employed to maximize the storage capacity and facilitate easy access to individual billets when needed. Implementing effective inventory management systems can help prevent unnecessary handling and potential damage. Safety measures are another significant challenge in steel billet storage. Due to their heavy weight and potential for sharp edges, it is essential to ensure proper handling and storage procedures to avoid accidents or injuries. Adequate training for personnel and the use of appropriate lifting equipment are necessary to maintain a safe working environment. Corrosion prevention is a critical concern in steel billet storage. Applying protective coatings, such as oil or rust inhibitors, can help shield the billets from moisture and prevent oxidation. Regular inspections and maintenance routines are also necessary to identify and address any signs of corrosion promptly. Lastly, minimizing material damage is crucial in steel billet storage. Proper handling techniques, such as avoiding dropping or dragging the billets, should be followed to prevent deformation or surface damage. Using suitable packaging or padding materials during transportation and storage can also help protect the billets from scratches or other physical impacts. In conclusion, the main challenges in the storage of steel billets revolve around maintaining proper environmental conditions, efficient space management, ensuring safety measures, preventing corrosion, and minimizing material damage. By addressing these challenges effectively, the longevity and quality of the steel billets can be preserved, resulting in enhanced operational efficiency and customer satisfaction.

- Q:How are steel billets used in the manufacturing of tools?

- Steel billets are used in the manufacturing of tools as they serve as the raw material for tool production. A steel billet is a semi-finished product that is typically a long, solid piece of steel with a square or rectangular cross-section. These billets are produced through a process called steelmaking, where iron ore is melted and converted into steel. To manufacture tools, the steel billets are first heated to a specific temperature, known as forging temperature. At this temperature, the steel becomes malleable and can be easily shaped and formed. The billets are then subjected to various forging techniques, such as hammering, pressing, or rolling, to shape them into the desired tool form. Once the billets are forged into the desired shape, they are further processed through machining operations like milling, drilling, grinding, or turning to achieve the required dimensions and surface finish. This stage involves removing excess material and refining the tool's shape and features. After the machining process, the tools are heat-treated to enhance their mechanical properties. Heat treatment involves subjecting the tools to specific heating and cooling cycles to alter their hardness, toughness, and wear resistance. This step is crucial as it ensures the tools can withstand the demanding conditions they will be exposed to during their use. Finally, the tools are finished and coated to provide protection against corrosion and improve their appearance. This can involve processes such as sandblasting, polishing, and applying protective coatings like chrome plating or powder coating. In summary, steel billets play a crucial role in the manufacturing of tools. They provide the raw material from which tools are forged, machined, heat-treated, and finished. The properties of the steel billets, such as their composition and metallurgical characteristics, contribute to the final quality, strength, and durability of the tools produced.

- Q:What are the different types of cutting techniques used for steel billets?

- Different cutting techniques are employed for steel billets, depending on the specific requirements of the project. Several commonly used techniques include: 1. Sawing: This traditional and widely utilized method involves cutting through the steel billet using a saw blade. It can be done manually or with automated sawing machines, making it suitable for both small and large billets. 2. Flame Cutting: Also known as oxy-fuel cutting, this technique employs a flame torch to heat the steel to its kindling temperature. Then, a jet of oxygen is introduced to burn through the metal. It is frequently used for cutting thicker billets and can be performed manually or with CNC-controlled equipment. 3. Plasma Cutting: By utilizing a high-velocity jet of ionized gas, plasma cutting melts and blows away the steel. This technique is particularly effective for cutting billets with complex shapes or contours. It is often automated and produces clean and precise cuts. 4. Waterjet Cutting: This technique involves the use of a high-pressure jet of water combined with abrasive particles to cut through the steel billet. It is ideal for materials sensitive to heat, as it minimizes heat-affected zones. Waterjet cutting is capable of handling various thicknesses and shapes of billets. 5. Laser Cutting: Laser cutting employs a high-powered laser beam to melt and vaporize the steel, resulting in a clean and precise cut. It is highly accurate and suitable for cutting intricate shapes and designs. Laser cutting is commonly automated and widely used in industrial settings. Factors such as desired precision, speed, material thickness, and budget must be considered when selecting the most appropriate cutting technique for steel billets. Each technique has its own advantages and limitations, and choosing the right one can significantly impact the quality and efficiency of the cutting process.

- Q:How is the quality of steel billets determined?

- The quality of steel billets is determined through a combination of physical and chemical tests. These tests are performed to ensure that the steel meets the required standards and specifications for its intended use. One of the primary methods to determine the quality of steel billets is through chemical analysis. This involves testing the composition of the steel to ensure it meets the desired levels of different elements such as carbon, manganese, silicon, and others. The chemical composition plays a crucial role in determining the strength, hardness, and other mechanical properties of the steel. In addition to the chemical analysis, various physical tests are conducted to assess the quality of steel billets. These tests include measuring the dimensions, weight, and straightness of the billets to ensure they meet the specified tolerances. Surface inspection is also performed to detect any defects, such as cracks, seams, or surface irregularities that could affect the performance of the steel. Mechanical tests are another crucial aspect of determining the quality of steel billets. These tests evaluate the mechanical properties of the steel, including its strength, ductility, toughness, and hardness. Tensile tests are commonly conducted to measure the maximum load a steel billet can withstand before breaking or deforming. Impact tests are also performed to assess the steel's ability to resist sudden shocks or impacts. Furthermore, non-destructive testing techniques are used to detect any internal defects or inconsistencies in the steel billets. These methods include ultrasonic testing, magnetic particle inspection, and radiographic testing. These tests help ensure that the steel is free from any hidden defects that could compromise its quality or structural integrity. Overall, the quality of steel billets is determined through a comprehensive evaluation that includes chemical analysis, physical tests, mechanical tests, and non-destructive testing. These methods ensure that the steel meets the required standards and specifications, providing assurance of its reliability and suitability for various applications.

- Q:How are steel billets used in the manufacturing of industrial compressors?

- Industrial compressors require steel billets as a crucial part of their manufacturing process. These billets, essentially semi-finished steel products in the shape of a rectangular solid, are the starting material for making different compressor components. To begin with, steel billets are heated to high temperatures and then passed through rolling mills to shape them into specific forms like bars, rods, or sheets. These processed steel billets are then used to fabricate important compressor components such as the crankshaft, connecting rods, cylinder blocks, and piston rings. The crankshaft, which converts the piston's reciprocating motion into rotational motion, is typically forged from a steel billet. The billet undergoes controlled heating, shaping, and machining processes to achieve the desired shape and strength necessary to withstand the high pressures and forces within the compressor. Likewise, connecting rods, responsible for connecting the piston to the crankshaft, are also made from steel billets. These billets are machined precisely and undergo various heat treatment processes to ensure optimal strength and durability. Cylinder blocks, the primary structural frame of the compressor, are often casted from steel billets. The billets are melted and poured into molds to achieve the desired shape. Once solidified, further machining is performed on the cylinder block to create the cylinder bores, mounting surfaces, and other necessary features. Moreover, steel billets are utilized for producing piston rings, which play a crucial role in maintaining proper compression and preventing leakage. The billets are machined and then subjected to heat treatment processes to enhance wear resistance and ensure a precise fit within the cylinder. In summary, steel billets are indispensable in the manufacturing of industrial compressors as they provide the raw material for creating vital components. The ability to shape and process steel billets enables the production of robust, durable, and high-performance compressors capable of meeting the demanding requirements of various industries.

- Q:Fish pole carbon cloth tcf. Vcf. Svf. Hcf. On behalf of what?

- CF: is the abbreviation of Carbon Fiber in English, which means carbon fiber in ChineseCarbon fiber index for T (ton), ordinary carbon cloth is generally 20T-30T.Domestic ordinary carbon fishing rod material is generally 24T carbon fiber cloth. The higher the T value, the higher the strength and elasticity of the material.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Prime quality prepainted galvanized steel 625mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords