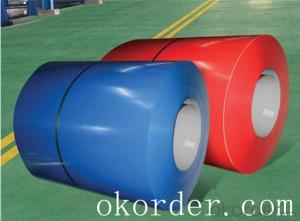

Prime quality prepainted galvanized steel 615mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

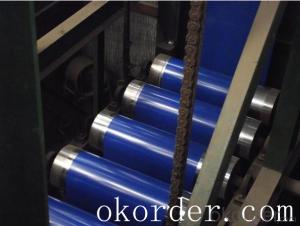

Construction building material galvanized color prepainted cold

rolled steel coil

Prepainted steel sheet is coated with organic layer, which provides higher anti-corrosion property and

a longer lifespan than that of galvanized steel sheets.

The base metals for prepainted steel sheet consist of cold-rolled, HDG electro-galvanized and hot-dip

Alu-zinc coated. The finish coats of prepainted steel sheets can be classified into groups as follows:

polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc

Standard and Grade :

Pre-paint galvanized steel coil | ||||

ASTM A755M-03 | EN10169:2006 | JISG 3312-2012 | ||

Commercial quality | CS | DX51D+Z | CGCC | |

Structure steel | SS GRADE 230 | S220GD+Z | CGC340 | |

SS GRADE 255 | S250GD+Z | CGC400 | ||

SS GRADE 275 | S280GD+Z | CGC440 | ||

SS GRADE 340 | S320GD+Z | CGC490 | ||

SS GRADE550 | S350GD+Z | CGC570 | ||

S550GD+Z | ||||

Application:

Outdoor | Roof, roof structure, surface sheet of balcony, frame of window, door of garage, rolled shutter door, booth, Persian blinds, cabana, etc |

Indoor | Door, isolater, frame of door, light steel structure of house, home electronic appliances, ect. |

- Q:Can steel billets be used for structural purposes?

- Yes, steel billets can be used for structural purposes. Steel billets are semi-finished steel products that are typically hot-rolled or forged into various shapes, including beams, columns, and other structural components. These billets are commonly used in construction and engineering projects to provide strength, durability, and load-bearing capabilities to structures. Steel billets are often further processed and shaped to meet specific design requirements before being incorporated into the construction process. They are widely utilized in the construction of buildings, bridges, highways, and other infrastructure projects due to their high strength-to-weight ratio and excellent mechanical properties. Additionally, steel billets can be easily welded, making them suitable for various structural applications.

- Q:What are the different types of cutting machines used for steel billets?

- Steel billets can be cut using different types of cutting machines, each designed to ensure efficient and precise cuts for desired dimensions and quality. 1. Bandsaw machines, widely utilized for cutting steel billets, employ a continuous loop of toothed metal blade guided around wheels. The billet is fed into the machine, and the blade cuts through it with high precision. 2. Circular saw machines, equipped with circular metal blades with teeth, are commonly used to cut large billets into smaller pieces. These machines can be operated manually or automatically, depending on the specific application. 3. Waterjet cutting machines employ a high-pressure stream of water mixed with abrasive materials to accurately cut through steel billets of varying thicknesses and shapes. This method is known for its versatility. 4. Plasma cutting machines utilize a plasma torch to cut steel billets. An electric arc generated by the torch passes through a small nozzle, releasing ionized gas. The heat from the arc melts the metal, while the gas blows away the molten material, resulting in a precise cut. 5. Laser cutting machines employ a high-powered laser beam to melt or vaporize steel billets, creating precise cuts with high speed and accuracy. 6. Shearing machines are commonly used to cut steel billets into specific lengths or shapes. These machines apply a shearing force using a blade or a pair of blades, making them suitable for high-volume production settings. The choice of cutting machine depends on factors such as desired cut quality, speed, and specific requirements of the steel billet cutting process, as each machine has its own advantages and limitations.

- Q:What are the different types of defects that can occur during casting of steel billets?

- There are several types of defects that can occur during the casting of steel billets. These include shrinkage cavities, porosity, cracks, inclusions, surface irregularities, and segregation. Shrinkage cavities occur due to the solidification process and can result in voids or cavities in the billet. Porosity refers to the presence of gas or air pockets within the billet, which can weaken its structure. Cracks can occur due to thermal stresses or improper cooling, leading to structural weaknesses. Inclusions are foreign materials such as oxides or non-metallic particles that can be trapped within the billet, impacting its quality. Surface irregularities refer to imperfections on the surface of the billet, which can affect its appearance and structural integrity. Segregation is the uneven distribution of alloying elements within the steel billet, leading to variations in the material's properties. These defects can impact the overall quality and performance of the finished steel product.

- Q:How are steel billets used in the production of hydraulic cylinders?

- Steel billets are an essential raw material used in the production of hydraulic cylinders. These billets are cylindrical in shape and made from high-quality steel. They serve as the starting point for the manufacturing process of hydraulic cylinders. The first step in utilizing steel billets is to heat them in a furnace. This heating process, known as hot rolling, allows the billets to become malleable and easier to work with. Once heated, the billets are then passed through a series of rollers, which shape and elongate them into the desired size and form. After the initial shaping, the billets are further processed through various machining operations. This includes drilling, boring, milling, and grinding, among others. These machining processes help create the necessary features and dimensions required for hydraulic cylinders, such as piston and rod bores, mounting holes, and ports for fluid flow. Once the machining operations are completed, the billets are subjected to heat treatment to enhance their mechanical properties. This involves either quenching and tempering or annealing, depending on the specific requirements of the hydraulic cylinder. Heat treatment helps improve the strength, hardness, and durability of the steel, ensuring that the hydraulic cylinder can withstand the high pressures and forces it will encounter during operation. Once the steel billets have been shaped, machined, and heat-treated, they are ready for the final assembly stage. At this point, other components such as pistons, rods, seals, and valves are added to complete the hydraulic cylinder. These components are carefully integrated with the billets to ensure proper functionality and reliable performance. In summary, steel billets play a crucial role in the production of hydraulic cylinders. They are heated, shaped, machined, heat-treated, and assembled to create the core structure of the cylinder. This ensures that the hydraulic cylinder possesses the necessary strength, durability, and precision required for its efficient operation in various industrial and mobile applications.

- Q:How do steel billets contribute to the overall seismic resistance of a structure?

- The overall seismic resistance of a structure is greatly improved by the presence of steel billets. When incorporated into concrete structures, steel billets act as reinforcement, boosting the structure's strength and longevity. This reinforcement enables the structure to better endure the forces and vibrations unleashed by earthquakes. The impressive tensile strength of steel billets enables them to efficiently absorb and distribute seismic energy, significantly decreasing the likelihood of structural failure during an earthquake. Moreover, steel billets have the capacity to be transformed into specialized structural elements, such as braces or shear walls, which are strategically positioned within the structure to counteract the lateral forces resulting from earthquakes. By utilizing steel billets, these structural elements are able to effectively absorb and disperse the seismic energy, successfully safeguarding the overall structure from substantial harm. Furthermore, steel billets are instrumental in the construction of seismic dampers, which are devices created to soak up and dissipate the energy generated by seismic events. When steel billet-based dampers are installed, the structure is able to significantly diminish the transfer of seismic energy to the building, thereby minimizing the potential for damage. Additionally, steel billets possess outstanding ductility, which is the capacity to deform without breaking. During an earthquake, structures experience considerable movement and vibrations. The ductile nature of steel allows it to flex and bend under these forces, proficiently absorbing seismic energy and preventing sudden, catastrophic failure of the structure. In conclusion, steel billets enhance the overall seismic resistance of a structure by providing additional strength and durability, facilitating the creation of specialized structural elements, enabling the construction of seismic dampers, and offering exceptional ductility. Their application elevates the structure's ability to withstand seismic forces, reducing the risk of damage and ensuring the safety of its occupants.

- Q:How are steel billets used in the production of agricultural implements?

- The production of agricultural implements heavily relies on steel billets. These billets serve as crucial raw materials that undergo diverse processes to attain the final products necessary for agricultural activities. Initially, steel billets go through heating before being passed through a rolling mill. This hot rolling process shapes and sizes the billets into steel bars or rods. Subsequently, these steel bars or rods undergo further processing to manufacture specific agricultural implements such as plows, harrows, cultivators, and seed drills. Throughout the manufacturing process, precise cutting, bending, and shaping techniques are applied to the steel billets to create the desired implements. Steel's strength and durability make it the preferred choice for agricultural equipment, as it can endure the demanding conditions faced in the field, including soil resistance and impact from rocks and other obstacles. Notably, steel billets are also utilized in the production of essential components like blades, tines, and tips, which are integral to the efficient functioning of agricultural machinery. These components are often hardened and tempered to enhance their wear resistance and toughness, ensuring they can withstand heavy use without sustaining damage. Moreover, steel billets are employed in the manufacturing of attachments and accessories that can be utilized alongside the primary agricultural implements. These attachments, such as plow points, disc blades, and planter plates, are designed to augment the functionality and versatility of the equipment, enabling farmers to adapt to diverse soil conditions and crop requirements. In conclusion, the significance of steel billets in the production of agricultural implements cannot be overstated. Through a variety of manufacturing processes, these billets are transformed into durable, reliable, and efficient tools that aid farmers in effectively and efficiently carrying out their tasks, ultimately contributing to heightened productivity within the agricultural sector.

- Q:What are the main factors affecting the corrosion resistance of steel billets?

- The main factors affecting the corrosion resistance of steel billets are the composition of the steel, the presence of impurities, the surface condition, and the surrounding environment. Firstly, the composition of the steel plays a crucial role in its corrosion resistance. Stainless steels, for example, contain a high amount of chromium and other alloying elements that form a protective oxide layer on the surface, thereby providing excellent corrosion resistance. On the other hand, carbon steels have a lower resistance to corrosion due to their higher carbon content and lack of alloying elements. Secondly, the presence of impurities in the steel can significantly impact its corrosion resistance. Inclusions, such as sulfur, phosphorous, and non-metallic inclusions, can act as initiation sites for corrosion, leading to localized corrosion and reduced overall resistance. Therefore, controlling the presence and distribution of impurities during the production of steel billets is essential for enhancing corrosion resistance. Moreover, the surface condition of the steel billets plays a vital role in their corrosion resistance. A smooth and clean surface promotes the formation of a protective oxide layer that acts as a barrier against corrosive substances. Conversely, rough or contaminated surfaces can lead to accelerated corrosion due to increased surface area and potential for localized corrosion. Lastly, the surrounding environment greatly influences the corrosion resistance of steel billets. Factors such as humidity, temperature, pH, and the presence of corrosive substances like acids, salts, or pollutants can accelerate corrosion. For instance, steel billets exposed to high humidity or corrosive chemicals are more susceptible to corrosion than those in dry or less corrosive environments. In summary, the corrosion resistance of steel billets is influenced by the composition of the steel, the presence of impurities, the surface condition, and the surrounding environment. It is crucial to consider these factors during the production and handling of steel billets to ensure their long-term durability and resistance to corrosion.

- Q:Does anyone know how much it costs to refine a ton of steel? What are the expenses involved?

- Electricity, water, wages, raw materials, raw materials loss, charges, oxygen, according to their own circumstances, as well as freight and other expenses, now the steel profits are not as good as before, a ton of net profit is about 100 yuan

- Q:Are steel billets used in the production of furniture?

- No, steel billets are not typically used in the production of furniture. Furniture is commonly made from materials such as wood, plastic, or metal alloys, but steel billets are usually used in the manufacturing of other steel products such as bars, rods, or sheets.

- Q:What are the different international trade regulations for steel billets?

- The trade of steel billets is governed by various international trade regulations, each serving different purposes. These regulations are in place to promote fair trade practices, guarantee product quality, and deter unfair competition. Here are some of the key regulations pertaining to steel billets: 1. Tariffs and import duties: To safeguard their domestic steel industries, many countries impose tariffs or import duties on steel billets. These levies differ significantly across nations and may undergo periodic revisions. Importers and exporters must be mindful of these tariffs and factor them into their pricing and cost calculations. 2. Measures against dumping: Anti-dumping regulations exist to prevent the sale of steel billets in foreign markets at prices below their production cost, which can harm domestic industries. If a country determines that steel billets are being dumped into their market, they may implement anti-dumping duties or other measures to address the issue. 3. Trade agreements and barriers: The trade of steel billets can be influenced by international trade agreements, such as free trade agreements or regional trade blocs. These agreements can reduce or eliminate tariffs and other trade barriers between participating countries, facilitating smoother trade flows. Conversely, countries not party to such agreements may face higher trade barriers, making it more challenging to export or import steel billets. 4. Quality and safety standards: Steel billets must meet specific quality and safety standards set by importing countries. These standards encompass dimensions, chemical composition, mechanical properties, and other attributes. Importers and exporters must ensure that their steel billets comply with these standards to avoid rejection or additional inspection upon arrival. 5. Export controls: Certain countries impose export controls or restrictions on selected commodities, including steel billets, to secure domestic supply or protect national security interests. These controls can limit the quantity or destination of steel billet exports, necessitating exporters to acquire licenses or permits before shipping. 6. Documentation and customs requirements: The international trade of steel billets necessitates accurate documentation and adherence to customs procedures. Exporters must furnish complete and precise documentation, comprising commercial invoices, packing lists, certificates of origin, and other pertinent documents. Importers must abide by customs requirements and settle any applicable duties or fees. Remaining up-to-date with these international trade regulations is crucial for businesses involved in the trade of steel billets. Regular monitoring of changes in tariffs, anti-dumping measures, trade agreements, and quality standards is necessary to ensure compliance and make well-informed business decisions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Prime quality prepainted galvanized steel 615mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords