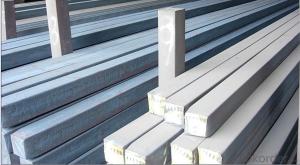

Prime Q275 120mm Square Alloy Steel Billet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prime Q275 120mm Square Alloy Steel Billet

Description of Prime Q275 120mm Square Alloy Steel Billet

1. Prepainted steel coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized or galvalume steel sheets.

2. The base metals for prepainted steel coil consist of cold rolled, HDGI Steel, electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of prepainted steel coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the prepainted steel coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The prepainted steel coils can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Main Feature of Prime Q275 120mm Square Alloy Steel Billet

Uncoated CR steel sheet

With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Prime Q275 120mm Square Alloy Steel Billet

A. Corrugated design makes it excellent waterproof performance

B. Materials as prepainted steel sheets, galvanized steel sheets, galvalume (Al-Zn coated sheets) are available to make corrugated sheet.

C.Those material are durable, anti-corrosion in bad weather for 20-30 years based on it's Zinc(Galvanized) coating or AZ (Galvalume) coating.

D. Different shape of the sheet make it suitable for any style of buildings.

E.Easy to install, no need special tools to fix the sheet.

F.Light weight due to high strength to weight ratio of steel. Light weight means easier handling lower shipping costs, easier installation

G. Different color is availbe base on the RAL Standard make your building more beautiful.

H. We will provide the best solutions if you don't have a exact idea of the specification you want for the steel sheet based on your weather conditions, engineering structure, construction budget and so on.

Specifications of Prime Q275 120mm Square Alloy Steel Billet

Product | Billet |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prime Q275 120mm Square Alloy Steel Billet

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q:How are steel billets used in the production of structural steel?

- Structural steel production relies heavily on steel billets, which are indispensable for the manufacturing process. These semi-finished steel products serve as the initial material, from which the transformation begins. To initiate the production of structural steel, scrap steel is melted in a high-temperature furnace. Once the steel reaches its liquid state, it is poured into molds that give it a solid, rectangular shape with a uniform cross-section. After the billets solidify, they are transported to a rolling mill. In this facility, the billets are reheated to a specific temperature and passed through a series of rollers. With each pass, the billets progressively undergo size and shape reduction. This crucial step, known as hot rolling, refines the mechanical properties of the steel. The hot-rolled billets then proceed to various techniques, including forging, extrusion, or casting, to achieve specific shapes and sizes required for structural applications. These techniques enable the transformation of the billets into beams, columns, plates, or other components necessary for construction projects. Once the desired shape is attained, the structural steel undergoes several treatments to enhance its strength, durability, and resistance to corrosion. Heat treatment, surface coating, and additional alloying elements may be employed for this purpose. Ultimately, the finished structural steel products find application in a wide range of projects, including the construction of buildings, bridges, and infrastructure. The consistent size and shape of the steel billets ensure that the resulting components possess the necessary strength, stability, and structural integrity to withstand the loads and stresses they will encounter. In conclusion, the importance of steel billets in structural steel production cannot be overstated. They serve as the fundamental material that undergoes various processes to achieve the desired shapes and sizes required for construction. The quality and uniformity of the billets are paramount in ensuring the strength and durability of the final structural steel products.

- Q:What are the environmental impacts of manufacturing steel billets?

- The manufacturing of steel billets has significant environmental impacts due to the extraction and processing of raw materials, energy consumption, and waste generation. 1. Raw material extraction: The primary raw materials used in steel billet production are iron ore, coal, and limestone. Extracting these resources often involves mining, which can lead to deforestation, habitat destruction, soil erosion, and water pollution. Additionally, the extraction of iron ore requires large amounts of water, which can strain local water supplies. 2. Energy consumption: Steel billet production requires high temperatures, typically achieved through the combustion of fossil fuels such as coal and natural gas. This process is energy-intensive and contributes to greenhouse gas emissions, including carbon dioxide (CO2) and nitrogen oxides (NOx), which are major contributors to climate change and air pollution. 3. Air pollution: The combustion of fossil fuels in steel production also releases particulate matter (PM), sulfur dioxide (SO2), and other pollutants into the air. These emissions can have detrimental effects on human health, causing respiratory problems and contributing to the formation of smog. 4. Water pollution: Steel manufacturing generates wastewater containing various chemicals and heavy metals. If not properly managed, these pollutants can contaminate water bodies, harming aquatic ecosystems and posing risks to human health. Additionally, the cooling of steel production equipment often requires large amounts of water, leading to water scarcity in some areas. 5. Waste generation: Steel production generates significant amounts of waste, including slag, dust, and sludge. These by-products can contain toxic substances and require careful handling and disposal to prevent soil and water contamination. To mitigate these environmental impacts, various measures can be implemented. These include adopting cleaner production technologies, improving energy efficiency, promoting recycling and reuse of materials, implementing effective waste management practices, and investing in renewable energy sources. Additionally, companies can work towards reducing their overall carbon footprint by implementing carbon capture and storage technologies or transitioning to low-carbon energy sources such as electric arc furnaces powered by renewable energy. Furthermore, government regulations and international agreements can play a crucial role in enforcing environmental standards and promoting sustainable practices in the steel manufacturing industry.

- Q:How do steel billets contribute to the manufacturing of agricultural equipment?

- Due to their versatility and durability, steel billets are essential for the manufacturing of agricultural equipment. These semi-finished steel products serve as the foundation for various agricultural machinery. To begin with, steel billets are crucial for creating the main structural components of agricultural equipment, including tractors, harvesters, plows, and tillers. These components, such as the chassis, frame, and axles, require a strong and sturdy material to withstand the heavy loads and harsh conditions encountered in agricultural operations. Steel billets provide the necessary strength and resilience to ensure the equipment's ability to endure the rigors of farming. Moreover, steel billets are used to manufacture smaller parts and mechanisms that are vital to the functioning of agricultural machinery. Gears, sprockets, shafts, and bearings, for instance, are commonly made from steel billets. These parts play a crucial role in transmitting power and facilitating the smooth operation of various agricultural equipment. Additionally, steel billets contribute to the longevity and reliability of agricultural equipment. The high strength and durability of steel ensure that the machinery can withstand the demanding agricultural environment, including exposure to moisture, dirt, and extreme temperatures. This durability reduces maintenance requirements and extends the equipment's lifespan, resulting in cost savings for farmers. Furthermore, steel billets offer the advantage of being easily shaped and molded into complex designs. This enables manufacturers to create customized agricultural equipment tailored to specific farming needs. The flexibility in design allows for the production of specialized machinery for various agricultural operations, such as planting, harvesting, irrigation, and livestock management. In conclusion, steel billets are indispensable in the manufacturing of agricultural equipment as they provide the necessary strength, durability, and versatility required for the demanding conditions of modern farming. Their contribution ensures that farmers have access to reliable and efficient machinery, ultimately increasing productivity and supporting sustainable agricultural practices.

- Q:What is the role of steel billets in the construction of power plants?

- The construction of power plants relies heavily on steel billets, which are semi-finished steel products utilized as raw materials in various processes involved in power plant production. A significant application of steel billets in this field is the creation of structural steel, which forms the framework of power plant structures like the main building, turbine halls, reactor buildings, and cooling towers. To produce the necessary structural components such as beams, columns, and trusses, steel billets are melted, refined, and cast into different shapes and sizes. These components provide essential support and stability to power plant infrastructure. Furthermore, steel billets are crucial in the manufacturing of equipment and machinery necessary for power generation. Turbine rotors, generator frames, and condensers are among the components produced using steel billets. These components play a vital role in the operation of power plants and contribute to efficient energy conversion. Moreover, steel billets are utilized in the construction of storage tanks, pipelines, and ducts within power plants. These structures are crucial for storing and transporting various fluids like water, steam, and fuel. Steel billets are transformed into sheets, plates, and tubes to fabricate these components, which are designed to withstand high pressures and temperatures. Steel billets are also highly durable and possess exceptional mechanical properties such as strength and toughness. These properties enable them to withstand the harsh operating conditions and loads experienced in power plants. They can endure high temperatures, corrosion, and stresses, ensuring the structural integrity and longevity of power plant infrastructure. In conclusion, steel billets are indispensable in power plant construction as they are employed in the production of structural components, equipment, and machinery. Their durability, strength, and versatility make them the preferred material in this industry. The use of steel billets guarantees the reliability and safety of power plants, ultimately contributing to the generation of electricity for various industries and communities.

- Q:What is the role of steel billets in the manufacturing of automotive transmission systems?

- Steel billets play a crucial role in the manufacturing of automotive transmission systems as they are the starting material for forging various components such as gears, shafts, and other critical parts. The billets are heated and then shaped through the forging process to achieve the desired dimensions and strength required for these transmission components. The use of steel billets ensures the durability, reliability, and overall performance of automotive transmission systems in vehicles.

- Q:What are the potential applications of steel billets in the textile industry?

- Steel billets can be used in the textile industry for various applications such as in the manufacturing of textile machinery, equipment, and components. They can be used to produce durable and sturdy parts like spindles, rollers, frames, and looms, which are essential for efficient textile production. Additionally, steel billets can be used in the construction of textile factories and warehouses, providing strength and stability to the infrastructure.

- Q:What are the different surface treatments for steel billets?

- The different surface treatments for steel billets include hot rolling, cold rolling, shot blasting, and pickling.

- Q:What are the different finishing processes used for steel billets?

- There are several different finishing processes used for steel billets to achieve the desired surface quality and dimensions. These processes include: 1. Hot rolling: This process involves passing the steel billets through a series of heated rollers to reduce their thickness and shape them into the desired profile. It can be used to produce a variety of finished products, such as bars, rods, and structural shapes. 2. Cold drawing: In this process, the steel billets are pulled through a series of dies at room temperature to reduce their cross-sectional area and improve their surface finish. Cold drawing is commonly used to produce high-quality steel bars and wires with precise dimensions and a smooth surface. 3. Peeling: Peeling is a machining process in which a thin layer of material is removed from the surface of the steel billets using a cutting tool. This process helps to improve the surface finish, remove any defects, and achieve tight dimensional tolerances. 4. Grinding: Grinding involves using an abrasive wheel or belt to remove material from the surface of the steel billets. It is commonly used to remove surface defects, such as scale and rust, and to achieve a smooth and uniform surface finish. 5. Polishing: Polishing is a finishing process that involves using abrasive materials, such as polishing compounds and buffing wheels, to create a smooth and reflective surface on the steel billets. It is often used to enhance the aesthetic appeal of the finished product and improve its resistance to corrosion. 6. Coating: Coating is a process in which a protective layer is applied to the surface of the steel billets to improve their resistance to corrosion and other environmental factors. Common coating methods include galvanizing, where a layer of zinc is applied to the surface, and painting, where a layer of paint or other protective material is applied. Overall, these finishing processes are essential in ensuring that steel billets meet the required specifications and standards for their intended applications. They help to improve the surface finish, dimensional accuracy, and overall quality of the finished steel products.

- Q:What are the potential applications of steel billets in the mining aftermarket?

- Steel billets have a wide range of potential applications in the mining aftermarket. They can be used for manufacturing heavy-duty machinery parts, equipment components, and tools used in mining operations. Additionally, steel billets can be used to fabricate structural supports, conveyor systems, and other infrastructure required for efficient mining processes. Their durability and strength make them ideal for withstanding the harsh conditions and heavy loads typically encountered in mining operations.

- Q:What is carbon accumulation?

- Generally refers to the polycarbonate, PC, is a kind of thermoplastic plastics, good transparency, good mechanical properties, surface hardness, common uses such as CD, plastic glasses, a fence, protective window, public places, vacuum cleaners, coffee machine, juicer barrel, refrigerator shelf, pure such as the bucket.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Prime Q275 120mm Square Alloy Steel Billet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords