Prime Hot Rolled Steel Sheets in Coils Steel Coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Description

Our main procucts are steel billet, steel plates, steel coils and wire rod. Moreover,our hot rolled coil and ship building plate are certificated respectively by CARES, CE from Eurpoean Union and CCS authentication from nine nations. Our products are widely used in various areas,such as millitary, aerospace, transportation, equipment manufacturing, shippin, petroleum pipe line, buildings etc.

| Production Name | Hot Rolled Steel Coils |

| Loading Port | Any Port in China |

| Thickness | 1.8mm-16mm |

| Width | 1000mm-1600mm |

| Coil Weight | 28 mt max |

| Material Grade | SS400\Q235\SAE1006\SAE1008 |

| Technique | Hot Rolled |

| Standard | GB \JIS\ASTM |

| Test | With Hydraulic Testing, Eddy Current , Infrared Test |

| Surface | 1) Bared |

| 2) Oiled | |

| Package | Standard Export Packing,Or at Customer’s Requirement |

| Sample | Common products, we can provide freely, for special production,we can depends on negotiation. |

| Payment | 100% L/C at sight, 30% T/T in advance |

| Delivery time | Within 10-25 days, according to quantity, asap save customer’s time |

| Certificate | ISO |

Product Images:

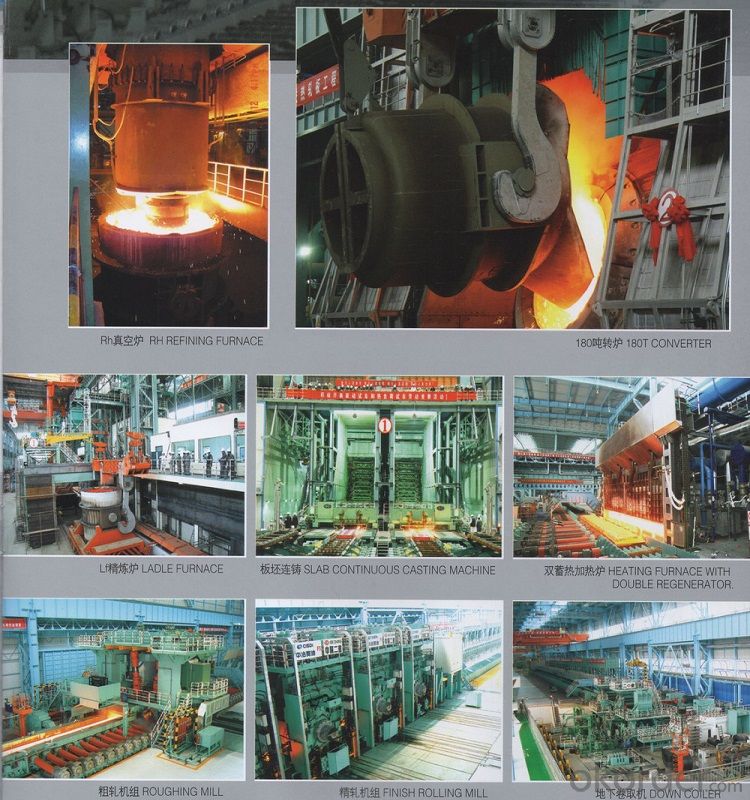

Product Process:

Our Service

Delivery time | 20-35days after receiving the payment of 30% deposit. |

Payment | -Irrevocable L/C at sight. |

-30% T/T in advance and 70% balance against copy of B/L. | |

Packing | -Standard Export Packing |

-According to customer's request. | |

Load port | Tianjin port, Shanghai port, Ningbo port or customer's request |

Feedback | If you have any questions, please feel free to contact us at any time possible. |

We will reply as soon as possible. | |

After Sale | Any questions of the production, please let me know directly by email or phone. |

We can deal with these issues on time, promise give you happy answers. | |

We focused on the after sale. Welcome send any comments to us. |

FAQ

1. Q: Where is your company located? How can I visit there?

A: Our company is located in Beijing, China. Welcome to visit us.

2. Q: Can I get sample and how long will it take?

A:Yes. We can supply sample. And you need to pay for courier.

3. Q: What's the MOQ?

A: Our MOQ is 25mt.

4. Q: What's the delivery time?

A: It will take about 30 days after TT or L/C.

5. Q: What is the payment terms?

A: T/T, L/C at sight

6. Q: How does your factory carry out quality control?

A: We attach great importance to quality control.Every part of our products has its own QC.

7. Q: What certificate do you have?

A: We have SGS, ISO9001 etc. Also we can apply any certificate if you need if the qty is OK.

- Q:my homework is a breif description on steel pipe. for plumbing/gas.please help me i dont have a clue where to start, something about the thread and where its used.Thanks,

- Here are a few quick things for you to check into on your own. First, there are a wide variety of materials that pipes can be made from such as carbon steel, stainless steel, aluminum, etc. Second, pipes can be of welded construction or seamless. Sometimes seamless pipes are called DOM (drawn over mandrel). Third, with the types of each pipe are a variety of grades. For example, steel pipe can be listed as A53, A106, A500, A513, etc. Each one of these grades has a different application because of their chemical composition and method of manufacture which effects its strength. Fourth, there is a difference between a 4 pipe and a 4 tube. Last, pipes for fluids are typically threaded with NPT threads. These threads are tapered so that as the pipes are screwed together they become tighter and therefore leak proof. I probably over complicated things but I hope this helped you. Good luck.

- Q:How are steel coils different from steel sheets?

- Steel coils and steel sheets are both made from the same material, which is steel. However, they differ in terms of their shape and size. Steel coils are long, continuous rolls of steel, usually wound up in a coil form, while steel sheets are flat, rectangular pieces of steel. The main difference lies in their applications - steel coils are commonly used in industries where large quantities of steel are required for manufacturing processes, such as automotive or construction, whereas steel sheets are often used for smaller-scale projects or as a raw material for further processing.

- Q:for a roof spanning 14.4m x 8.4m on a residential house, is it better to use timber trusses or steel trusses? the priorities are; ease of construction, price, insulation (want to keep heat out, i am in a tropical country), durability, flexibility, minimal load on foundations.please help. thank you :-)

- U will to find details on metal trussesin constructing materials AND development through BINDRA AND ARORA and u may additionally to find them in MCKAY(B.M.C).About steel doors and windows search the net u can search in google or yahoo u will to find it . Ok bye bye all of the exceptional.

- Q:How are steel coils used in the production of lighting fixtures?

- Steel coils are an essential component in the production of lighting fixtures. These coils are typically made of high-quality steel, which provides durability and strength to the final product. In the manufacturing process, the steel coils are first uncoiled and then passed through a series of machines. These machines cut and shape the steel into various parts and components required for lighting fixtures. The steel is often bent, stamped, or rolled to create the desired shapes and sizes. These parts may include the base, frame, arms, or other structural elements of the lighting fixture. Once the steel components are formed, they are then further processed and finished. This may involve welding, polishing, or coating the steel to enhance its appearance and protect it from corrosion. After the steel parts are finalized, they are assembled with other components like electrical wiring, bulbs, shades, and switches to create the complete lighting fixture. The use of steel coils in lighting fixture production ensures that the finished products are sturdy, long-lasting, and able to withstand various environmental conditions. Steel's strength allows for the creation of intricate designs and shapes, enabling manufacturers to produce lighting fixtures that are not only functional but also aesthetically pleasing. Overall, steel coils play a crucial role in the production of lighting fixtures by providing the necessary strength, durability, and versatility required for these products.

- Q:What are the key players in the steel coil manufacturing industry?

- The key players in the steel coil manufacturing industry are typically large multinational companies that have significant market share and influence. Some of the prominent players in the industry include: 1. ArcelorMittal: As the world's largest steel producer, ArcelorMittal is a major player in the steel coil manufacturing industry. They operate in more than 60 countries and have a diversified product portfolio. 2. Nippon Steel Corporation: Nippon Steel is a leading Japanese steelmaker and one of the largest steel coil manufacturers globally. They have a strong presence in automotive and construction sectors. 3. POSCO: Based in South Korea, POSCO is a major player in the steel industry, including steel coil manufacturing. They are known for their high-quality products and advanced technology. 4. Baosteel Group Corporation: Baosteel is the largest steelmaker in China and one of the largest globally. They have a wide range of steel products, including steel coils, and are known for their strong research and development capabilities. 5. Thyssenkrupp AG: Thyssenkrupp is a German multinational conglomerate with a significant presence in the steel coil manufacturing industry. They have a diverse product range and focus on innovation and sustainability. 6. United States Steel Corporation: As a leading American steel producer, United States Steel Corporation plays a crucial role in the steel coil manufacturing industry. They have a strong presence in the automotive, construction, and energy sectors. 7. JFE Holdings, Inc.: JFE Holdings is a Japanese steel conglomerate and one of the key players in the steel coil manufacturing industry. They have a wide range of steel products and are known for their quality and customer-oriented approach. These are just a few of the key players in the steel coil manufacturing industry, and there are many other companies that contribute to this sector. The industry is highly competitive, and these companies continuously strive to innovate, improve efficiency, and meet the ever-evolving demands of the market.

- Q:What are the challenges in coil blanking for high-strength steel?

- Some challenges in coil blanking for high-strength steel include the increased hardness and strength of the material, which can lead to greater wear and tear on cutting tools. Additionally, high-strength steel may have less ductility, making it more prone to cracking or breaking during the blanking process. The higher tensile strength and spring-back characteristics of the steel also require precise control and adjustment of blanking parameters to ensure accurate and consistent part dimensions.

- Q:Why?Which one should i get? I am just starting to learn Guitar. Which one would be better for me? What is the difference? I already got the acoustic nylon but i might return it... if the steel is better.

- Depends on what kind of music you want to play. Nylon string guitars are used for classical music, and sometimes for jazz, occasionally for folk music. Steel string acoustic guitars are used for almost everything else -- rock, pop, country, bluegrass, folk, blues, jazz, you-name-it. Some people will tell you that beginners should start on nylon strings because they're supposed to be softer on your fingertips but unless you plan to continue playing classical or jazz or folk on your nylon string guitar for some time to come, you're wasting your money. If you want to play rock, pop, country or almost anything else, get a steel string guitar, put light-gauge steel strings on it. Your fingertips are going to be sore for the first few weeks no matter what kind of strings you have on your guitar -- you might as well start off on a guitar that will have the sound you want for the kind of music you actually want to play. Nylon string guitars also have wider necks and fingerboards than steel string guitars, so if you have smaller hands, a steel string guitar will probably be more comfortable for you to play. Hope this helps.

- Q:How are steel coils inspected for mechanical properties?

- Steel coils are inspected for mechanical properties through a combination of destructive and non-destructive testing methods. Destructive methods involve conducting tensile, hardness, and impact tests on samples taken from the coils. Non-destructive methods, such as ultrasonic or magnetic particle testing, are also employed to detect surface and internal defects without damaging the coils. These inspections ensure that the steel coils meet the required mechanical specifications for their intended applications.

- Q:What are the different packaging options for steel coils?

- The different packaging options for steel coils include wooden pallets, steel cradles, eye-to-sky or eye-to-wall packaging, and steel banding or strapping. These options are used to ensure the safe transportation and storage of steel coils, preventing damage and maintaining their shape and quality.

- Q:What are the different methods of steel coil surface cleaning?

- Some of the different methods of steel coil surface cleaning include pickling, shot blasting, and chemical cleaning. Pickling involves immersing the steel coil in an acid solution to remove oxides and scales. Shot blasting uses high-speed particles to remove rust, scale, and paint from the surface. Chemical cleaning involves using specialty chemicals to dissolve contaminants and restore the steel coil's surface.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Prime Hot Rolled Steel Sheets in Coils Steel Coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords