Prime Hot Rolled Chequered Steel Sheets China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Item specifice

Standard:

ASTM,GB,JIS

Technique:

Hot Rolled

Shape:

Round

Surface Treatment:

Galvanized,Oiled,Dry

Steel Grade:

Q195,Q215,Q235,SS400-SS490

Certification:

ISO,SGS,BV,CE

Thickness:

1.8mm-16mm

Width:

1000mm-1600mm

Length:

requirement

Net Weight:

23mt

Packaging:

Standard Export Packing

Product Description:

| Grade | Q235B,Q345B,SS400ASTM A36, St37-2 |

| Standard | GB, BS, EN, ASTM, JIS |

| Payment | L/C |

| Delivery | 25 working days after confirmed the order |

| Application | Floor board, factory stair boards, deck board, car boards ,staircases, lorry beds, elevator floors |

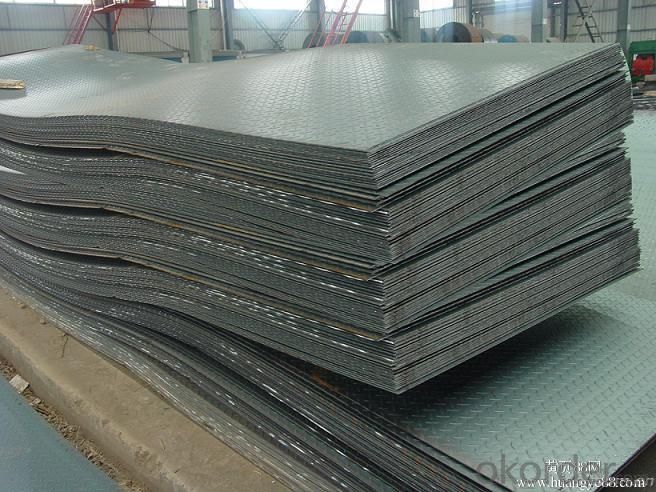

2.Product Images

3.Our Service

4.FAQ

1. Q: Where is your company located? How can I visit there?

A: Our company is located in Beijing, China. Welcome to visit us.

2. Q: What's the MOQ?

A: Our MOQ is 23mt.

3. Q: What's the delivery time?

A: It will take about 30 days after TT or L/C.

4. Q: What is the payment terms?

A: T/T, L/C at sight

5. Q: How does your factory carry out quality control?

A: We attach great importance to quality control.Every part of our products has its own QC.

- Q:What are the advantages of using pre-painted steel coils?

- There are several advantages of using pre-painted steel coils. Firstly, they offer a wide range of color options, allowing for greater design flexibility and customization. Secondly, pre-painted steel coils have a protective coating that enhances their durability and resistance to corrosion, extending their lifespan. Additionally, pre-painted steel coils are available in various finishes, such as matte, glossy, or textured, providing aesthetic appeal. Furthermore, these coils are ready for immediate use, saving time and labor costs associated with painting on-site. Overall, pre-painted steel coils offer convenience, durability, versatility, and enhanced aesthetics, making them a preferred choice in various industries.

- Q:How are steel coils used in the production of industrial equipment?

- Steel coils are a vital component in the production of industrial equipment. These coils are large, flat rolled sheets of steel that are typically used as raw material in various manufacturing processes. Firstly, steel coils are used for fabrication purposes, where they are cut, shaped, and welded together to create the framework or structure of industrial equipment. This includes machinery, heavy-duty vehicles, storage tanks, and other industrial components. The coils provide the necessary strength and durability to withstand the demanding conditions faced by industrial equipment. Additionally, steel coils are often formed into specific shapes to produce parts and components for industrial machinery. These parts can include gears, shafts, bearings, brackets, and many others. The versatility of steel allows it to be easily manipulated and fabricated into different shapes and sizes, making it an ideal material for such applications. Moreover, steel coils are also used in the construction of industrial equipment, particularly in the manufacturing of boilers, heat exchangers, and pressure vessels. These coils are typically formed into tubes or pipes, which are then welded or brazed together to create the necessary structure for these equipment. The high strength and heat resistance properties of steel make it the preferred material for such applications, ensuring the safe and efficient operation of industrial processes. In summary, steel coils play a crucial role in the production of industrial equipment. They are used as raw material for fabrication, forming parts and components, and constructing crucial equipment such as boilers and pressure vessels. The durability, strength, and versatility of steel make it an indispensable material in the manufacturing industry.

- Q:How are steel coils unloaded from a truck?

- Steel coils are typically unloaded from a truck using a combination of heavy-duty forklifts, cranes, and specialized equipment. The coils are carefully lifted and positioned onto the ground or a designated storage area, ensuring proper safety measures and precautions are followed to prevent any damage or accidents during the unloading process.

- Q:Can steel coils be coated with chrome?

- Yes, steel coils can be coated with chrome.

- Q:What is the maximum length of a steel coil?

- The maximum length of a steel coil can vary depending on various factors such as the manufacturing process, transportation limitations, and storage capabilities. However, it is common for steel coils to have a maximum length of around 30 meters (100 feet) or even longer in some cases.

- Q:I found the cold steel kukri machete online and I am very impressed and am thinking of ordering it. A friend of mine said that the cold steel kukri machete is nothing compared to the KaBar Kukri Machete. I was wondering if other people who own these machetes could tell me the good and the bad of each machete. Such as what they have been able to cut. If they break easily and such. Thanks in advance.

- I don't know about the Kabar Kukri, but I can vouch for the Cold Steel product. Cold Steel tests all of their products in extreme conditions, check out their website and look up their free video cold proof. They do things like cut a side of beef, bones in, in half with one strike, or cut a 3 inch thick rope 1,000 times with the same knife and then still shave the hair off their arms, and also they take their knives and stab them through car doors and hang weights on them. So a Cold Steel Kukri is guaranteed to do its job well (which incidentally is used to sever heads). They usually have pretty good prices too. The only thing you need to worry about is the legality of ordering that weapon wherever you live. Cold Steel is totally legit (annoyingly so) and will not mail/sale weapons to areas that have banned the purchase and ownership of them. So good luck with your purchase!

- Q:What are the common manufacturing defects in steel coils?

- Common manufacturing defects in steel coils include surface defects such as scratches, pits, and dents, as well as internal defects like inclusions, cracks, and voids. Other common defects can include uneven thickness, waviness, and coil set.

- Q:I am building a steel type competative team. my team so far isempolem, skarmory , Metagross, magnezone, lucario, ferrothorn.

- Good choice in pokemon. As for moves and EVs and all that... its kinda up to how exactly you wanna play your steel team, but heres what I can think up off the top of my head: Empoleon: Mixed Attacker. Swords Dance and Aqua Jet for strong priority attacking, with two special attacks (preferrably one water and one other non steel non water attack) Skarmory: Physical wall. Skarmory is know to be an amazing physical wall. So pump HP and defense EVs into it. Impish nature is best, and try to get Roost, Whirlwind, and Brave Bird on it. Stealth Rock or Spikes for entry hazard damage. Metagross: Physical attacker. Bullet Punch is nice since Metagross is kinda slow, and Hammer Arm is decent since it hardly cares about a speed drop. Earthquake and Zen Headbutt aren't bad either. Magnezone: Bulky Special Attacker. The teams a really physical one, so having a special attacker is nice so other physical walls don't mess you up too bad. Its main attacking moves should be Thunderbolt and Flash Cannon. Sturdy and Magnet Pull are both good abilities, which one you go with is up to you. Lucario: Physical Sweeper. Max out Lucario's Attack and Speed EVs, its defenses are too low for it to take repeated hits. Close Combat and Extremespeed are Lucario staples. The other 2 moveslots depend on you. An elemental punch is good for coverage. Earthquake... is Earthquake, its good to have. There's other options too. Ferrothorn: Ferrothorn has a number of options, usually involving its great bulk. Look this one up on Smogon. Other good steel types would include: Bronzong, Scizor, Forretress. Excadrill is good, but its far better in a sandstorm team than on an all steel team (Sand Rush+Swords Dance+Focus Sash+Attack=death). Hope this helps.

- Q:Can steel coils be coated with thermally insulating materials?

- Yes, steel coils can be coated with thermally insulating materials.

- Q:I need to say how a bottle opener is made, would it be made from steel and can this be coloured? How?

- Steel can be plated(Chrome),Blackened(Black Oxide),Powder coated(color of your choose).All of this is done to prevent rust.All of these aforementioned processes can be worn off through being used.I suggest polished Stainless steel.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Prime Hot Rolled Chequered Steel Sheets China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords