Prime Hot Dipped Cable Bridge C Channel Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 PCS

- Supply Capability:

- 38000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Prime Hot Dipped Cable Bridge C Channel Steel Details

| Standard: | AISI,ASTM,BS,DIN,GB,JIS,ASTM /GB/ BS | Dimensions: | 1.0MM--8.0MM | Grade: | Q195-235,SPCC,SPCH,Q195-Q235 |

| Place of Origin: | Hebei China (Mainland) | Brand Name: | CNBM | Model Number: | GTLM-CS-026 |

| Shape: | C Channel | Application: | Steel Structure, Building,1).Steel Structure. 2).Engeneering | Perforated Or Not: | Is Perforated |

| Length: | any length as per ur request. Common not more than 12m | Thickness: | 4.1.0--8.0mm | Surface: | 1). Puch hole or not 2). Painting or not 3). Galvanized,bright |

| Name: | C channel steel/ C section steel | Raw material: | hot rolled strip, cold rolled strip, galvanized steel strip |

Packaging & Delivery

| Packaging Detail: | bundles by steel strip,in container or as ur request |

| Delivery Detail: | 20days after received deposit or affirm contract |

Prime Hot Dipped Cable Bridge C Channel Steel Specifications

Size | Weight (kg/m ) | Size | Weight (kg/m ) |

80×40×20×2.5 | 3.925 | 180×60×20×3 | 8.007 |

80×40×20×3 | 4.71 | 180×70×20×2.5 | 7.065 |

100×50×20×2.5 | 4.71 | 180×70×20×3 | 8.478 |

100×50×20×3 | 5.652 | 200×50×20×2.5 | 6.673 |

120×50×20×2.5 | 5.103 | 200×50×20×3 | 8.007 |

120×50×20×3 | 6.123 | 200×60×20×2.5 | 7.065 |

120×60×20×2.5 | 5.495 | 200×60×20×3 | 8.478 |

120×60×20×3 | 6.594 | 200×70×20×2.5 | 7.458 |

120×70×20×2.5 | 5.888 | 200×70×20×3 | 8.949 |

120×70×20×3 | 7.065 | 220×60×20×2.5 | 7.4567 |

140×50×20×2.5 | 5.495 | 220×60×20×3 | 8.949 |

140×50×20×3 | 6.594 | 220×70×20×2.5 | 7.85 |

160×50×20×2.5 | 5.888 | 220×70×20×3 | 9.42 |

160×50×20×3 | 7.065 | 250×75×20×2.5 | 8.634 |

160×60×20×2.5 | 6.28 | 250×75×20×3 | 10.362 |

160×60×20×3 | 7.536 | 280×80×20×2.5 | 9.42 |

160×70×20×2.5 | 6.673 | 280×80×20×3 | 11.304 |

160×70×20×3 | 8.007 | 300×80×20×2.5 | 9.813 |

180×50×20×2.5 | 6.28 | 300×80×20×3 | 11.775 |

180×50×20×3 | 7.536 | ||

180×60×20×2.5 | 6.673 |

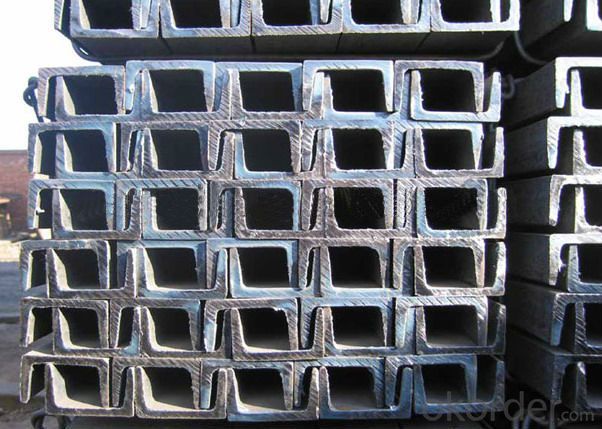

Prime Hot Dipped Cable Bridge C Channel Steel Pictures

- Q:What are the different load distribution techniques for steel channels?

- There are several load distribution techniques that can be used for steel channels. 1. Uniform Load Distribution: This technique involves distributing the load evenly across the entire length of the steel channel. It is commonly used when the load is evenly distributed or when there is no specific point of concentrated load. 2. Concentrated Load Distribution: In this technique, the load is concentrated at specific points along the steel channel. This is often used when there are specific areas where the load is expected to be higher, such as at support points or connection joints. 3. Variable Load Distribution: This technique involves varying the load distribution along the length of the steel channel. It is used when the load is not evenly distributed and varies from one point to another. This can be achieved by adjusting the spacing between the supports or using additional support mechanisms such as beams or braces. 4. Combination Load Distribution: Sometimes, a combination of load distribution techniques is used to optimize the structural integrity of the steel channel. This may involve using uniform load distribution for most of the length, with concentrated load distribution at specific points where the load is expected to be higher. The choice of load distribution technique depends on various factors such as the nature of the load, the structural requirements, and the intended use of the steel channel. It is important to consider these factors and consult with a structural engineer to determine the most suitable load distribution technique for a specific application.

- Q:What is the wall thickness of national standard 8* channel steel?

- 8# channel steel GB wall thickness should be 5.0mm (mm),

- Q:How do steel channels contribute to sustainable design in buildings?

- Steel channels contribute to sustainable design in buildings in several ways. Firstly, steel is a highly durable and long-lasting material, which means that buildings constructed with steel channels have a longer lifespan, reducing the need for frequent renovations or replacements. This results in less waste generation and a lower environmental impact. Secondly, steel is a recyclable material, which means that steel channels can be recycled and reused after the end of their life cycle. This helps to reduce the demand for new steel production and the associated energy consumption and greenhouse gas emissions. Additionally, steel channels allow for efficient and flexible design options, enabling the construction of lighter and more efficient structures. This leads to reduced material consumption, improved energy efficiency, and lower carbon footprint during the construction and operation phases of the building. Furthermore, steel channels are often used in prefabricated construction methods, which can significantly reduce construction waste, minimize on-site disruption, and improve overall construction efficiency. Overall, the use of steel channels in building design contributes to sustainability by promoting durability, recyclability, energy efficiency, and reduced waste generation, making it a preferred choice for sustainable building practices.

- Q:What are the different types of steel channel accessories?

- Various industries and construction projects commonly utilize different types of steel channel accessories. Some of the most frequently used options include: 1. Brackets: These accessories offer additional support and stability to the structure by securing steel channels in place, preventing any movement or sagging. 2. Connectors: Used to join multiple steel channels together, connectors come in various designs, such as corner or straight connectors, ensuring a strong and secure connection. 3. End caps: These cover the exposed ends of steel channels, providing a polished appearance while also protecting against damage or corrosion. 4. Mounting hardware: This category encompasses bolts, screws, and brackets that attach steel channels to walls, floors, or other surfaces, guaranteeing a secure installation. 5. Clips and clamps: These accessories secure cables, pipes, or other equipment to steel channels, offering a reliable and organized solution for managing and securing various components. 6. Hangers: Used to suspend or hang equipment, pipes, or cables from steel channels, hangers are commonly employed in HVAC systems, electrical installations, and plumbing applications to provide support and prevent sagging. 7. Slotted channels: Specifically designed with slots or holes along the length, these channels allow for easy and adjustable mounting of accessories like brackets, clamps, or hangers without requiring additional drilling or modifications. Overall, steel channel accessories play a vital role in enhancing the functionality, stability, and appearance of steel channel structures across a wide range of applications.

- Q:Are steel channels suitable for the mining industry?

- Yes, steel channels are commonly used in the mining industry due to their numerous qualities and suitability for various applications. Steel channels are known for their strength, durability, and resistance to wear and tear, making them ideal for the harsh and demanding conditions found in mining operations. Steel channels are often used in the construction of infrastructure within mines, such as support structures, walkways, platforms, and conveyors. Their ability to withstand heavy loads and provide stability makes them a reliable choice for these applications. Additionally, steel channels can be easily welded, allowing for efficient installation and customization to meet specific mining requirements. Furthermore, steel channels offer excellent corrosion resistance, which is crucial in mining environments where exposure to moisture, chemicals, and other corrosive substances is common. This resistance ensures the longevity of the equipment and structures used in mining operations, reducing maintenance costs and downtime. Another advantage of steel channels is their versatility. They come in a variety of sizes and shapes, allowing for flexible designs and configurations that can be adapted to different mining applications. Steel channels can also be galvanized or coated to provide additional protection against corrosion or environmental factors. In summary, steel channels are highly suitable for the mining industry due to their strength, durability, resistance to corrosion, and versatility. Their use in various mining applications enhances safety, efficiency, and longevity, making them an integral part of the industry's infrastructure.

- Q:16A channel steel size requirements are national standards Oh!

- The national standard for channel steels is "hot rolled steel" GB/T706-2008

- Q:What are the different methods of protecting steel channels from fire?

- There are several methods available to protect steel channels from fire. One common method is to apply a fire-resistant coating or paint to the surface of the steel channels. These coatings are designed to provide a protective barrier that can withstand high temperatures and prevent the steel from reaching its critical temperature, which is when it begins to lose its structural integrity. These coatings can be applied through various techniques such as spraying, brushing, or rolling. Another method is to encase the steel channels in fire-resistant materials such as concrete or gypsum board. This creates a physical barrier that insulates the steel from the heat of the fire, preventing it from reaching its critical temperature. This method is commonly used in construction projects where fire resistance is a critical requirement. Intumescent coatings are another effective method of protecting steel channels from fire. These coatings are specially designed to expand when exposed to high temperatures, forming an insulating char layer that protects the steel from the fire. Intumescent coatings can be applied as paints or sprays and are commonly used in buildings, particularly in areas where steel channels are exposed to fire risks. In addition to these methods, fireproofing materials such as fireproof wraps or blankets can be used to protect steel channels. These materials are typically made from fire-resistant fibers or fabrics and are wrapped around the steel channels to provide insulation and prevent the transfer of heat. Finally, proper fire safety measures such as installing fire suppression systems, smoke detectors, and fire alarms in the vicinity of steel channels can also help protect them from fire. These measures can help detect and control fires at their early stages, minimizing the risk of damage to the steel channels. Overall, there are various methods available to protect steel channels from fire, ranging from coatings and encasements to fireproofing materials and fire safety systems. The choice of method depends on factors such as the specific requirements of the project, the level of fire protection needed, and the budget constraints.

- Q:10kV and below the distribution cabinet in the room, the basic channel should be higher than the indoor ground level? Which specification is clearly defined?

- Power distribution cabinet (box), power distribution cabinet (box) and lighting distribution cabinet (box), measuring cabinet (box), is the last stage equipment of power distribution system. Power distribution cabinet is the general term of motor control center.

- Q:Are steel channels suitable for data center construction?

- Data center construction can benefit greatly from the use of steel channels. These channels, also known as C-channels, possess the necessary qualities of strength, stability, and flexibility required for such projects. Their durability and ability to withstand heavy loads make them a popular choice for framing walls, ceilings, and floors. The advantages of using steel channels in data center construction are numerous. Firstly, their exceptional load-bearing capabilities enable them to support the weight of server racks, equipment, and infrastructure. In data centers with high equipment density and significant server and networking device weights, this is of utmost importance. Furthermore, steel channels contribute to the structural stability of a data center, ensuring its security and strength. They are resistant to bending and buckling, providing a solid framework capable of withstanding both internal and external forces. This is particularly beneficial in areas prone to seismic activities or extreme weather conditions. In addition, steel channels allow for easy installation of various utilities necessary in data centers, such as electrical wiring, cable trays, and cooling systems. They can be designed with pre-punched holes or slots, simplifying the routing of cables and pipes throughout the facility. Moreover, steel channels offer versatility in design and construction. They can be easily modified and adjusted to meet specific layout requirements, facilitating efficient use of space and flexibility for future expansions or modifications. This adaptability is crucial in data centers where technology and infrastructure needs are constantly evolving. In conclusion, steel channels are undeniably suitable for data center construction. Their strength, stability, flexibility, and versatility make them an ideal choice for creating a robust and efficient infrastructure to support the critical operations of a data center.

- Q:Are steel channels suitable for outdoor applications?

- Yes, steel channels are suitable for outdoor applications. Steel is known for its durability, strength, and resistance to environmental factors such as corrosion and weathering. These qualities make steel channels ideal for outdoor use where they can withstand various conditions and provide structural support in construction projects, outdoor installations, and other outdoor applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Prime Hot Dipped Cable Bridge C Channel Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 PCS

- Supply Capability:

- 38000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords