Prime ETP Tinplate for Metal Packaging of Dry Food

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 200000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Prime Electrical Prime ETP Tinplate for Metal Packaging (Manufacturer) Description

Due to Tinplate packaging`s good seal, nature, dark, robustness and unique decorative metal charm, it has a wide range of coverage in the packaging container industry,and common international packaging varieties. With a variety of CC tinplate material, DR materials, chrome plated and constantly enrich and promotion and development of packaging products and technology, tinplate packaging has promoted with innovation.

Because of its strong antioxidant and diverse styles, beautifully printed, tinplate containers are very popular and loved by customers, and they are widely used in food packaging, pharmaceutical packaging, commodity packaging, instrumentation, packaging, industrial packaging and so on.

Tinplate packaging has high strength, good formability, and many advantages, such as its compatibility in the international market. Therefore, tinplate packaging container is the largest amount of sheet metal packaging in the world.

2.Main Features of the Prime Electrical Prime ETP Tinplate for Metal Packaging (Manufacturer)

Appearance – Electrolytic Tin Plate is characterized by its beautiful metallic luster. Products with various kinds of surface roughness are produced by selecting the surface finish of the substrate steel sheet.

Paintability and printability – Electrolytic Tin Plates have excellent paintability and printability. Printing is beautifully finished using various lacquers and inks.

Formability and strength – Electrolytic Tin Plates have got very good formability and strength. By selecting a proper temper grade, appropriate formability is obtained for different applications as well as the required strength after forming.

Corrosion resistance – Tinplate has got good corrosion resistance. By selecting a proper coating weight, appropriate corrosion resistance is obtained against container contents. Coated items should meet 24 hour 5 % salt spray requirement.

Solderability and weldability – Electrolytic Tin Plates can be joined both by soldering or welding. These properties of tinplate are used for making various types of cans.

Hygienic – Tin coating provides good and non toxic barrier properties to protect food products from impurities, bacteria, moisture, light and odours.

Safe – Tinplate being low weight and high strength makes food cans easy to ship and transport.

Eco friendly – Tinplate offers 100 % recyclability.

Tin is not good for low temperature applications since it changes structure and loses adhesion when exposed to temperatures below – 40 deg C.

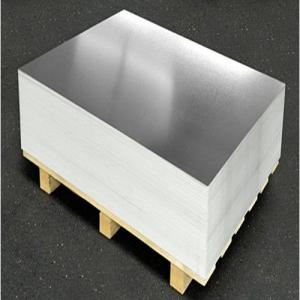

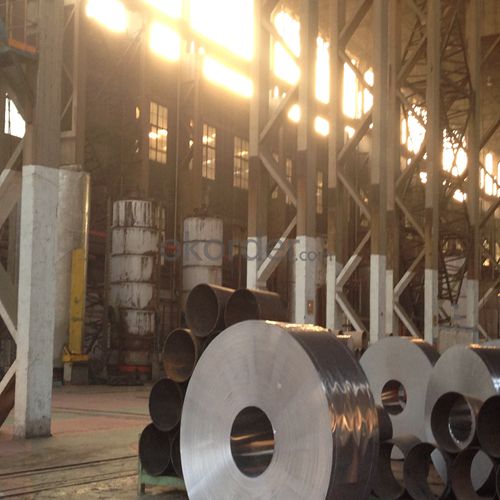

3.Prime Electrical Prime ETP Tinplate for Metal Packaging (Manufacturer) Images

4.Prime Electrical Prime ETP Tinplate for Metal Packaging (Manufacturer) Specification

Standard | ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

|

Material | MR,SPCC |

Thickness | 0.15mm - 0.50mm |

Width | 600mm -1150mm |

Temper | T1-T5 |

Annealing | BA & CA |

Coil Inner Diameter | 508mm |

Weight | 6-10 tons/coil 1~1.7 tons/sheets bundle |

Passivation | 311 |

Oil | DOS |

Surface | Finish,bright,stone,matte,silver |

5.FAQ of Prime Electrical Prime ETP Tinplate for Metal Packaging (Manufacturer)

- How are the Electrolytic Tin Plates specified?

The Electrolytic Tin Plates are specified as per the steel base, extent of tempering, the coating weight, annealing method and the surface finish.

- How many types there are for base steels?

The base steels are of three types: Type MR, L, D

-What your tinplate material is used for ?

Tinplate is widely used for the packaging of products. Such as food cans,

beverage cans, pet cans, closures, general line cans and so on.

Printed Tinplate is offered!!

-How to place .an order or contact you ?

Please send us Email. we will give you a quick response in seconds .

- How is your quality ?

All our quality is prime even the secondary quality . We have many years experience

In this field with serious quality control standard . Advanced equipment, We welcome your visit to our factory .

- Q:What are the different types of tinplate finishes?

- There are several different types of tinplate finishes, including bright finish, stone finish, matte finish, and lacquered finish.

- Q:How is tinplate coated with protective lacquer?

- Tinplate is coated with a protective lacquer through a process called electrostatic spraying. The tinplate is first cleaned and degreased to ensure proper adhesion of the lacquer. Then, the lacquer is applied to the tinplate using an electrostatic spray gun, which charges the lacquer particles and attracts them to the metal surface. This creates a uniform and durable coating that provides protection against corrosion and enhances the tinplate's overall appearance.

- Q:What are the advantages of tin packaging?

- Shapes: tinplate cans can be made into various shapes according to different needs, such as cans, cans, cans, circular elliptical horseshoe and trapezoid etc, can satisfy the different needs of product packaging, and the packaging container more change, promote sales.

- Q:What are the typical transportation requirements for tinplate?

- The typical transportation requirements for tinplate include ensuring proper packaging and protection to prevent damage during handling and shipment. Tinplate is commonly transported in rolled or flat sheets, coils, or fabricated containers, depending on the specific product and its intended use. It is crucial to handle tinplate with care to avoid scratches, dents, or corrosion that could impact its quality. Additionally, proper labeling and documentation are necessary to comply with regulatory and customs requirements during transportation.

- Q:What are the different surface finishes available for tinplate?

- There are several surface finishes available for tinplate, including bright, stone, matte, and lacquered finishes.

- Q:What are the different ways to recycle tinplate packaging?

- There are several different ways to recycle tinplate packaging. One common method is to separate the tinplate from other materials, such as paper or plastic, and then melt it down to be used in the production of new tinplate products. Another way is to repurpose the tinplate packaging by transforming it into new and creative items, such as decorative storage containers or art pieces. Additionally, tinplate packaging can also be collected and sent to recycling facilities where it will be properly processed and recycled into various new products.

- Q:Does tinplate require any specific handling or storage conditions?

- Yes, tinplate does require specific handling and storage conditions. It should be protected from moisture and kept in a dry environment to prevent rusting. Additionally, it is recommended to store tinplate in a cool and well-ventilated area to maintain its quality and prevent any potential damage.

- Q:How is tinplate coated for corrosion resistance?

- Tinplate is coated for corrosion resistance through a process called electrolytic tinplating. During this process, a thin layer of tin is electroplated onto the surface of the tinplate, creating a protective barrier against corrosion.

- Q:What are the common forms of corrosion that affect tinplate?

- The common forms of corrosion that affect tinplate include uniform corrosion, pitting corrosion, and crevice corrosion.

- Q:Can tinplate be used for microwaveable packaging?

- No, tinplate cannot be used for microwaveable packaging as it is a metal material and will cause sparks or fire when exposed to microwave radiation.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Prime ETP Tinplate for Metal Packaging of Dry Food

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 200000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords