Prime ETP for Metal Package of Industrial or Chemical Useage

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Structure of Prime ETP for Metal Package of Industrial or Chemical Useage Description

Electrolytic Tinplate undoubtedly enjoys the pride of place as a packaging medium especially for food. It owes its unique position to its "nine layer sandwich structure", each of which contributes to its eminence as a packing material. The steel base of electrolytic tinplate provides the necessary strength and formability for can fabrication. The tin-iron alloy layer provides the bond between the steel and free tin layer. The free tin layer is not only responsible for the attractive bright finish and ease of solderability but is also non-toxic- a factor of vital importance in food packaging!

2.Main Features of the Prime ETP for Metal Package of Industrial or Chemical Useage

Tinning is the process of thinly coating sheets of wrought iron or steel with tin, and the resulting product is known as tinplate. It is most often used to prevent rust.

While once more widely used, the primary use of tinplate now is the manufacture of tin cans. Formerly, tinplate was used for cheap pots, pans and other holloware

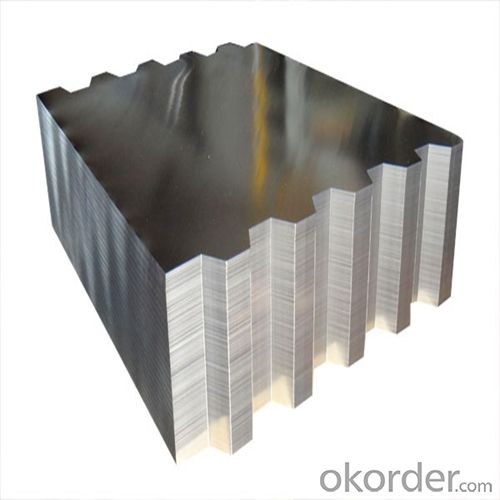

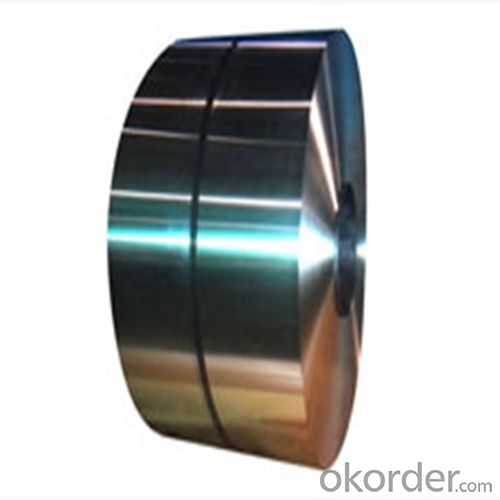

3.Prime ETP for Metal Package of Industrial or Chemical Useage Images

4.Prime ETP for Metal Package of Industrial or Chemical Useage Specification

Specification of :

Standard: ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

Material: MR,SPCC

Thickness:0.15mm - 0.50mm

Width: 600mm -1150mm

Temper: T1-T5

Annealing: BA & CA

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil 1~1.7 tons/sheets bundle

Passivation:311

Oil: DOS

Surface: Finish,bright,stone,matte,silver

5.FAQ of Prime ETP for Metal Package of Industrial or Chemical Useage

- What is tinning and how does it work?

Tinning is the process of thinly coating sheets of wrought iron or steel with tin, and the resulting product is known as tinplate. It is most often used to prevent rust.

- Do you only have prime quality tinplate?

We can supply both prime and second quality tinplate.

- Q:What are the different closure mechanisms for tinplate cans?

- The different closure mechanisms for tinplate cans include: slip cover lids, press-on lids, pull-tab lids, twist-off lids, and peel-off lids.

- Q:Can tinplate be used for bakery packaging?

- Yes, tinplate can be used for bakery packaging. It is a durable and food-safe material that provides protection to bakery products from external factors such as moisture and light. Tinplate also offers a visually appealing packaging option and can be easily decorated or customized to enhance the product's presentation.

- Q:How does tinplate contribute to the protection of musical instruments?

- Tinplate contributes to the protection of musical instruments by providing a durable and corrosion-resistant coating, which helps prevent rust and damage caused by moisture and environmental factors. Additionally, tinplate can be used in the manufacturing of instrument cases, offering a lightweight yet strong material that safeguards instruments during transportation and storage.

- Q:What are the common sizes and thicknesses of tinplate?

- The common sizes of tinplate range from 0.14mm to 0.60mm in thickness, with typical widths varying from 600mm to 1200mm.

- Q:Can tinplate be used for packaging products with sensitive electronic components?

- Yes, tinplate can be used for packaging products with sensitive electronic components. Tinplate is known for its excellent electrical conductivity and corrosion resistance, making it an ideal choice for protecting sensitive electronic components from external factors such as moisture and oxidation. Additionally, tinplate offers good mechanical strength and can be easily formed into various shapes, providing secure packaging for these components.

- Q:How does tinplate packaging contribute to product differentiation?

- Tinplate packaging contributes to product differentiation by providing a unique and attractive look that distinguishes a product from its competitors. The use of tinplate allows for creative and eye-catching designs, which can effectively communicate the brand's identity and create a memorable impression on consumers. Additionally, tinplate packaging offers durability and protection, ensuring that the product remains in good condition throughout its shelf life. This enhances the overall perceived value of the product and sets it apart from alternatives, thus contributing to product differentiation.

- Q:Can tinplate packaging be used for gardening products?

- Yes, tinplate packaging can be used for gardening products. Tinplate is a durable and corrosion-resistant material that can protect gardening products such as seeds, fertilizers, or small tools from moisture, light, and other external factors. Additionally, tinplate packaging can be designed with attractive graphics and labels to enhance product visibility and appeal to gardening enthusiasts.

- Q:How is tinplate priced?

- Tinplate is typically priced based on various factors including market demand, production costs, and quality of the tin coating. Additionally, market fluctuations and trade policies can also affect the pricing of tinplate.

- Q:What are the advantages of using tinplate for paint cans?

- There are several advantages of using tinplate for paint cans. Firstly, tinplate is highly resistant to corrosion, ensuring that the paint cans remain durable and do not rust over time. Secondly, tinplate has excellent sealing properties, preventing any leakage or evaporation of the paint. Additionally, tinplate is lightweight and easy to handle, making it convenient for transportation and storage. Lastly, tinplate is a sustainable choice as it is recyclable, contributing to environmental conservation efforts.

- Q:What are the main applications of tinplate in the tobacco industry?

- The main applications of tinplate in the tobacco industry include the production of cigarette packaging, such as cigarette boxes and tins, which provide a protective and durable barrier for the tobacco products. Tinplate is also used for the inner lining of cigarette packets to maintain the freshness and quality of the tobacco. Additionally, tinplate is utilized for the production of cigarette rolling papers, filters, and other tobacco-related accessories.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Prime ETP for Metal Package of Industrial or Chemical Useage

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords