Prime Electrical ETP Tinplate for Metal Packaging in Coils

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Prime Electrical ETP Tinplate for Metal Packaging Description

Electrolytic Tin Plate Coils and Sheets for Foods Metal Packaging, is one thin steel sheet with a coating of tin applied by electrolytic deposition. Tinplate made by this process is essentially a sandwich in which the central core is strip steel. This core is cleaned in a pickling solution and then fed through tanks containing electrolyte, where tin is deposited on both sides. As the strip passes between high-frequency electric induction coils, it is heated so that the tin coating melts and flows to form a lustrous coat.

2.Main Features of the Prime Electrical ETP Tinplate for Metal Packaging

Appearance – Electrolytic Tin Plate is characterized by its beautiful metallic luster. Products with various kinds of surface roughness are produced by selecting the surface finish of the substrate steel sheet.

Paintability and printability – Electrolytic Tin Plates have excellent paintability and printability. Printing is beautifully finished using various lacquers and inks.

Formability and strength – Electrolytic Tin Plates have got very good formability and strength. By selecting a proper temper grade, appropriate formability is obtained for different applications as well as the required strength after forming.

Corrosion resistance – Tinplate has got good corrosion resistance. By selecting a proper coating weight, appropriate corrosion resistance is obtained against container contents. Coated items should meet 24 hour 5 % salt spray requirement.

Solderability and weldability – Electrolytic Tin Plates can be joined both by soldering or welding. These properties of tinplate are used for making various types of cans.

Hygienic – Tin coating provides good and non toxic barrier properties to protect food products from impurities, bacteria, moisture, light and odours.

Safe – Tinplate being low weight and high strength makes food cans easy to ship and transport.

Eco friendly – Tinplate offers 100 % recyclability.

Tin is not good for low temperature applications since it changes structure and loses adhesion when exposed to temperatures below – 40 deg C.

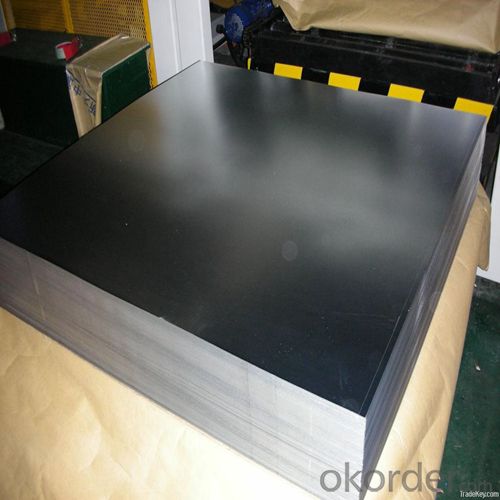

3.Prime Electrical ETP Tinplate for Metal Packaging Images

4.Prime Electrical ETP Tinplate for Metal Packaging Specification

Standard | ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

|

Material | MR,SPCC |

Thickness | 0.15mm - 0.50mm |

Width | 600mm -1150mm |

Temper | T1-T5 |

Annealing | BA & CA |

Coil Inner Diameter | 508mm |

Weight | 6-10 tons/coil 1~1.7 tons/sheets bundle |

Passivation | 311 |

Oil | DOS |

Surface | Finish,bright,stone,matte,silver |

5.FAQ of Prime Electrical ETP Tinplate for Metal Packaging

- How are the Electrolytic Tin Plates specified?

The Electrolytic Tin Plates are specified as per the steel base, extent of tempering, the coating weight, annealing method and the surface finish.

- How many types there are for base steels?

The base steels are of three types: Type MR, L, D

- Q:How to test the tightness of tin metal cans?

- The empty tank which has been cleaned can be dried by 35, and the pressure or pressure leak test shall be carried out according to the equipment condition of each unit. B.1 pressure leak test, the empty tank will be carefully injected into the water until eight or nine into full, the rubber ring will be placed in the appropriate plexiglass plate at the opening side of the roll, so that it can be sealed. Start the vacuum pump, turn off the bleeder valve, hold down the cover by hand, control the pumping, and make the vacuum gauge rise from 0Pa to 6.8X10 PA (510mmHg) for more than 1min, and keep the vacuum above 1min.

- Q:How is tinplate coated?

- Tinplate is coated through a process called electrolytic tinning, where a thin layer of tin is deposited onto the surface of a steel sheet. This is achieved by immersing the sheet in an electrolyte solution and passing an electric current through it, causing tin ions to migrate and deposit onto the steel surface. This coating provides tinplate with corrosion resistance and enhances its appearance.

- Q:Soup with tin cans loaded also need high temperature sterilization?

- At present, there are DN400x500, DN600x1000, DN800*1000, DN900*1000 and DN900x1500 in the market, and the small sterilization pot with boilers is heated by steam. If not, heating by electricity can also be done. The phone won't be left. If you need any service from the manufacturer, you can call me from Hi. The key is not to sell, eliminating confusion is the key.

- Q:How is tinplate coated for stationery and office supplies?

- Tinplate is typically coated for stationery and office supplies through a process called electrolytic tinplating, where a thin layer of tin is electroplated onto the surface of the steel. This coating provides protection against corrosion and enhances the aesthetic appeal of the product.

- Q:Can tinplate be used for chemical storage containers?

- Yes, tinplate can be used for chemical storage containers. Tinplate is a type of steel coated with a thin layer of tin, which provides excellent resistance against corrosion. This makes it suitable for storing various chemicals, as it helps to prevent any reaction between the stored substance and the container. Additionally, tinplate is durable and has good strength, making it a reliable option for chemical storage.

- Q:How does tinplate packaging withstand extreme temperatures?

- Tinplate packaging is able to withstand extreme temperatures due to its high melting point and excellent heat resistance properties. The tin coating on the steel base provides a protective layer that helps to prevent the metal from warping or melting when exposed to extreme heat. Additionally, the structural integrity of tinplate packaging is maintained even in extreme cold temperatures, making it a reliable choice for preserving the quality and safety of various products.

- Q:How does tinplate packaging contribute to product protection against breakage?

- Tinplate packaging provides a strong and durable barrier that helps protect products from breakage. The rigid nature of tinplate offers excellent resistance against external impacts, preventing the product from getting damaged during handling, transportation, or storage. Additionally, tinplate's ability to withstand compression and stacking ensures that the product remains intact even when subjected to pressure. Its protective qualities make tinplate packaging highly reliable in safeguarding products and reducing the risk of breakage.

- Q:How does tinplate packaging contribute to product visibility?

- Tinplate packaging contributes to product visibility by offering a sleek and shiny surface that enhances the visual appeal of the product. The reflective nature of tinplate allows for better light reflection, making the packaging stand out on store shelves and attracting consumers' attention. Additionally, tinplate can be easily printed and decorated with vibrant designs, logos, and product information, further enhancing product visibility and brand recognition.

- Q:Can tinplate be used for packaging baby food and formula?

- Yes, tinplate can be used for packaging baby food and formula. Tinplate is a commonly used material for food packaging due to its durability, corrosion resistance, and ability to protect against light and oxygen. It is also considered safe for food contact and can be easily sterilized, making it suitable for packaging sensitive products like baby food and formula.

- Q:How is tinplate manufactured?

- Tinplate is manufactured through a process called electroplating, where a thin layer of tin is applied onto a base metal, usually steel. The steel is first cleaned and then immersed into an electrolyte solution containing tin ions. An electric current is then passed through the solution, causing tin ions to be attracted and deposited onto the steel surface, forming a layer of tin. This tin coating provides the steel with corrosion resistance and enhances its appearance, making it suitable for various applications such as food and beverage packaging.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Prime Electrical ETP Tinplate for Metal Packaging in Coils

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords