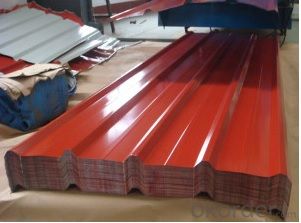

PRIME COLD ROLLED WAVE GALVANIZED METAL SHEET

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Brief Introduction

PRIME COLD ROLLED WAVE GALVANIZED METAL SHEET

--- Corrosion resistance: Pre-coated steel offers excellent corrosion resistance achived through continuous hot DIP galvanization and corrosion resistant primer/polyester coating. Protection is achieved when zinc and steel are together in the presence of moisture; The zinc protects the steel by galvanic action

Product Features

. Traditional aesthetics outlook

. Suitable for new house or renovation.

. Less joints, watertight

. Long life service

. Tedun also provide relative ridge cap, fasteners and other accessories

Product Specification

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.13mm~3.0mm,

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

FAQ

How long will we receive the goods ?

45days after receiving workable L/C

how do you control the quality ?

we have our own quality control department ,we will arrange QC person to see the production line ,when goods finish ,before shipment ,our QC person will check the quality as per our test report request ,if the goods is ok ,then we issue the test report ,and we allow the goods shipping ,otherwise will not allow ship the goods.

- Q:How do steel strips contribute to vibration damping in various applications?

- Steel strips contribute to vibration damping in various applications because of their high density and stiffness. When attached or integrated into structures, they absorb and dissipate the energy generated by vibrations, reducing their amplitude and frequency. This helps to minimize unwanted noise, prevent structural damage, and enhance overall stability and performance in applications such as machinery, automotive, and construction. The steel strips act as a damping material, converting mechanical energy into heat, thereby attenuating vibrations and improving the overall comfort, safety, and efficiency of the system.

- Q:What is the typical thickness of steel strips?

- The typical thickness of steel strips can vary depending on the specific application and industry, but it commonly ranges from 0.1 mm to 6 mm.

- Q:How are steel strips used in the production of kitchen utensils?

- Steel strips are commonly used in the production of kitchen utensils as they are cut, shaped, and formed into various utensil components such as blades, handles, or frames. These strips provide the necessary strength, durability, and corrosion resistance required for kitchen utensils, ensuring they can withstand regular use and maintain their quality over time.

- Q:How do steel strips handle high-impact applications?

- Steel strips are highly durable and have excellent strength, making them well-suited for high-impact applications. They can effectively absorb and redistribute the energy generated from impacts, minimizing any potential damage or deformation. Additionally, steel strips are typically resistant to bending and breaking, allowing them to withstand intense forces without compromising their structural integrity.

- Q:Can steel strips be used in the aerospace industry?

- Yes, steel strips can be used in the aerospace industry. They are commonly used for various applications such as structural components, fasteners, and support brackets. Steel strips offer high strength, durability, and heat resistance, making them suitable for aerospace manufacturing and maintenance.

- Q:What is the maximum thickness of steel strips?

- The maximum thickness of steel strips typically depends on various factors such as the type of steel, manufacturing process, and intended application. However, for most industrial purposes, steel strips are commonly available in thicknesses ranging from 0.1 mm to 6 mm.

- Q:Can steel strips be used in the production of household appliances?

- Yes, steel strips can be used in the production of household appliances. Steel strips are often used to manufacture the outer casings, frames, and structural components of household appliances such as refrigerators, ovens, and washing machines due to their strength, durability, and resistance to corrosion.

- Q:How are steel strips shaped and formed?

- Rolling is the process by which steel strips are shaped and formed. To achieve this, large steel billets or slabs are passed through a series of rolling mills. These mills apply pressure and force to the metal, transforming it into thin, flat strips. The rolling mills are equipped with rollers that gradually reduce the thickness of the steel strip at each stage. The process begins with heating the steel billet to a high temperature, making it more malleable. The hot billet is then fed into the first rolling mill, where it passes through a set of rollers that progressively decrease the strip's thickness. Afterward, the strip is cooled and transferred to the next rolling mill, where the process is repeated. Each rolling mill has a specific roll configuration designed to give the steel strip the desired shape and dimensions. This can include flat rolls, which evenly compress the strip to reduce thickness, or shaped rolls, which create specific cross-sectional profiles like round, square, or rectangular shapes. Once the desired shape is achieved, the steel strip may undergo additional processing to enhance its mechanical properties. Annealing or tempering can be employed, involving heating and cooling the strip to alter its microstructure and improve strength, ductility, and hardness. Aside from rolling, steel strips can also be formed using cold forming or stamping techniques. Cold forming shapes the steel strip at room temperature using dies or molds, commonly used for creating complex shapes and precise dimensions. On the other hand, stamping involves cutting or shaping the steel strip using a press with a die specifically designed for the desired shape. In summary, the shaping and forming of steel strips combine heating, rolling, and other forming techniques to achieve the desired shape, dimensions, and mechanical properties. These processes play a crucial role in the manufacturing of various steel products, including automotive parts, construction materials, and household appliances.

- Q:How do steel strips perform in flexible assemblies?

- Steel strips perform well in flexible assemblies as they are strong, durable, and resistant to bending and deformation. They provide stability and reinforcement to the assembly, ensuring that it maintains its shape and structure even when subjected to various forces and movements. Additionally, steel strips offer excellent corrosion resistance, making them suitable for a wide range of applications in flexible assemblies.

- Q:What are the different surface engraving methods for steel strips?

- There are several surface engraving methods for steel strips, including laser engraving, etching, chemical engraving, and mechanical engraving. Each method has its own advantages and is suitable for different applications. Laser engraving offers high precision and can create intricate designs, while etching uses chemicals to remove material and create patterns. Chemical engraving involves the use of acid or other chemicals to etch the surface, and mechanical engraving uses cutting tools to physically remove material. The choice of method depends on factors such as desired design complexity, production volume, and cost considerations.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PRIME COLD ROLLED WAVE GALVANIZED METAL SHEET

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords