Price of 1kg 304 price Stainless Steel Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Description

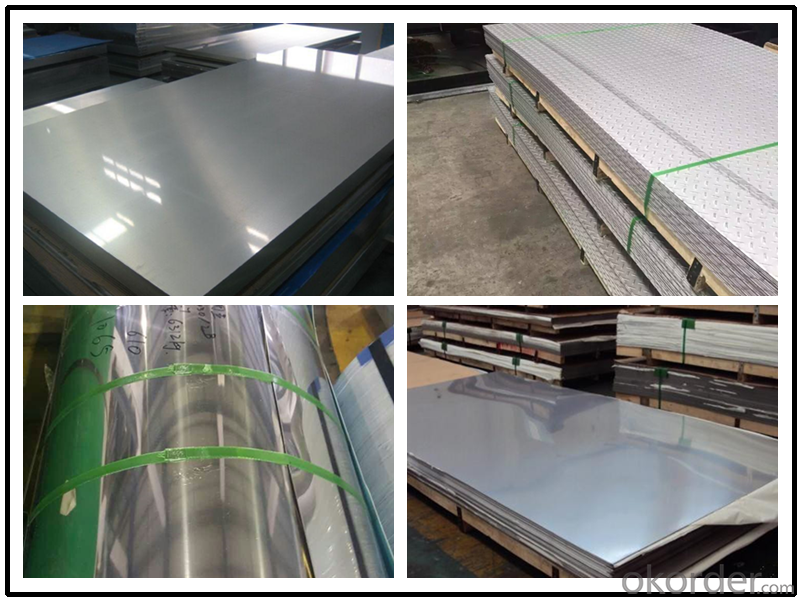

Price of 1kg stainless steel sheet

Thickness: 0.3-60mm

Width: 600-2000mm

Surface: No.1, 2B, Hairline, No.4, BA, 8K mirror finish

( material grades we can supply including: 304 / 304L / 201 / 316L / 321 / 310S / 430 / 410 / 410S / 409L / 409)

Product name | Price of 1kg stainless steel sheet |

Standard | ASTM, AISI, JIS, GB, DIN |

Mill | TISCO , LISCO, ZPSS, BAOSTEEL, SKS |

Certification | ISO Certificate, Mill Test Certificate |

MOQ | 1 Metric Ton |

Terms of delivery | FOB, CFR, CIF |

Time of shipment | Normally delivery within 10 days from stocks. |

Stocks | Ready In stocks |

Chemical Composition | ||||

SS304 | SS 316 | SS430 | SS201 | |

Ni(%) | 8.0-10.5 | 10.0-14.0 | -- | 0.8-1.2 |

Cr(%) | 18.0-20 | 16.0-18.0 | 16.0-18.0 | ≤0.15 |

C(%) | ≤0.08 | ≤0.08 | ≤0.12% | ≥40 |

Elong(%) | ≥40 | ≥40 | ≥22 | |

Hardness | HB≤187,HRB≤90, HV≤200 | HB≤187, HRB≤90 HV≤200 | HB≤183, HRB≤88 HV≤200 | HB≤241,HRB≤100, HV≤240 |

Stainless Steel Sheet Series

Stainless Steel Polished Sheet (8K Mirror, Hairline, Grit 240,320)

Embossed Stainless Steel Sheet

Etched Stainless Steel Sheet,

PVD Colored Stainless Steel Sheet,

Perforated Stainless Steel Plate

Chequered Stainless Steel Sheet

Packaging & Shipping

Application

- Q:Can stainless steel sheets be used for HVAC systems?

- Certainly! HVAC systems can utilize stainless steel sheets. Due to its exceptional resistance to corrosion, durability, and ability to withstand high temperatures, stainless steel is a favored material for HVAC systems. It finds frequent application in various HVAC components, including ductwork, vents, and heat exchangers. Stainless steel sheets offer a sleek and hygienic surface, safeguarding air quality by preventing the accumulation of dust, dirt, and other pollutants. Moreover, stainless steel is effortlessly cleaned and maintained, rendering it an ideal option for HVAC systems demanding regular upkeep and cleaning.

- Q:Can stainless steel sheets be used for roofing?

- Indeed, roofing can utilize stainless steel sheets as they possess qualities such as durability, longevity, and resistance against corrosion, rust, and weathering. As a result, stainless steel serves as an exceptional choice for various roofing applications, including industrial, commercial, and residential projects. These sheets offer remarkable strength and the ability to endure adverse weather conditions, including heavy rain, snow, and wind. Furthermore, stainless steel exhibits fire resistance and remains free from warping or cracking, thereby ensuring a dependable and secure roofing solution. However, it is crucial to acknowledge that stainless steel roofing materials can be pricier than alternative options, necessitating the consideration of cost factors.

- Q:How about stainless steel grades?

- 304 - that is, 18/8 stainless steel. GB is 0Cr18Ni9. 309 - better temperature resistance than 304. 316 - after 304, second of the most widely used steel grades are used mainly in the food, pharmaceutical and pharmaceutical industries, and molybdenum is added to obtain a special corrosion resistant structure. Because of its better resistance to chloride corrosion than 304, it is also used as "ship steel". SS316 is usually used in nuclear fuel recovery devices. Grade 18/10 stainless steel usually meets this application level. [

- Q:What are the different types of stainless steel sheet coatings available?

- There are several different types of stainless steel sheet coatings available, including electroplated coatings, powder coatings, and organic coatings. Electroplated coatings involve the deposition of a thin layer of metal onto the stainless steel surface, providing enhanced corrosion resistance. Powder coatings involve the application of a dry powder that is then heated and cured to form a protective layer. Organic coatings, such as paints or lacquers, are also commonly used to provide corrosion resistance and improve aesthetic appeal.

- Q:Are stainless steel sheets suitable for automotive applications?

- Stainless steel sheets are indeed well-suited for automotive applications. With its durability, strength, and corrosion resistance, stainless steel proves to be an ideal material for various automotive components. It finds extensive use in body panels, exhaust systems, trim, and other parts that necessitate resistance to weathering, heat, and chemical exposure. Moreover, stainless steel sheets offer remarkable aesthetic appeal as they can be polished to a mirror-like finish or brushed to achieve a sleek and contemporary appearance. Additionally, stainless steel is easily malleable, enabling the production of intricate shapes and designs crucial in the automotive manufacturing process. All in all, stainless steel sheets provide the essential properties and versatility to fulfill the demanding requirements of automotive applications.

- Q:Are stainless steel sheets resistant to staining?

- Yes, stainless steel sheets are highly resistant to staining. This is because stainless steel contains a high percentage of chromium, which forms a protective layer on the surface of the metal. This layer, known as the passive layer, prevents the steel from reacting with oxygen and moisture in the environment, making it resistant to rust and corrosion. Additionally, the smooth and non-porous surface of stainless steel makes it difficult for stains to penetrate and adhere to the material. While stainless steel sheets may still show some signs of staining over time, they can be easily cleaned and restored to their original appearance with minimal effort. Overall, stainless steel sheets are a popular choice for applications where stain resistance is important, such as in kitchens, hospitals, and industrial settings.

- Q:Can stainless steel sheets be used for furniture or fixtures?

- Stainless steel sheets are suitable for furniture or fixtures, offering durability and versatility. This material is resistant to corrosion, making it an ideal choice for items exposed to moisture or high humidity. It can be utilized in various ways, such as tabletops, countertops, shelves, cabinets, and decorative accents. The sheets are easily adaptable to different shapes and sizes, enabling customization to meet specific design needs. Moreover, stainless steel's modern and sleek appearance has made it a favored option for contemporary and industrial-style furniture and fixtures.

- Q:What are the different surface finishes available for stainless steel sheets?

- Stainless steel sheets come in a variety of surface finishes, each with its own unique characteristics and aesthetics. Let's explore some of the options available: 1. The No.1 Finish is the most commonly used finish for stainless steel sheets. It has a rough and dull appearance with visible grain lines. This finish is achieved through hot rolling and is suitable for applications where a rough finish is acceptable. 2. For a smooth and slightly dull surface, the No.2B Finish is ideal. It is obtained by cold rolling and annealing the stainless steel. This finish is commonly used for kitchen appliances, architectural accents, and decorative purposes. 3. Similar to the No.2B Finish, the No.2D Finish also involves cold rolling and annealing. However, it has a smoother and shinier appearance, making it suitable for applications that require a more polished look. 4. The No.3 Finish, also known as a brushed finish, is achieved by polishing the stainless steel with abrasive belts or brushes. It creates a unidirectional satin-like appearance, often used for decorative purposes in architecture and interior design. 5. If you desire a more refined and smoother appearance, the No.4 Finish is the way to go. This finish is obtained by polishing the stainless steel with finer abrasive belts or brushes than the No.3 Finish. It is commonly used for decorative purposes, such as elevator panels, kitchen equipment, and automotive trim. 6. For a highly reflective surface, the No.8 Finish, also known as a mirror finish, is perfect. This finish is achieved by continuously polishing the stainless steel with finer abrasive materials until a glossy, mirror-like appearance is obtained. It is ideal for architectural and decorative applications. 7. The Hairline Finish is achieved by mechanically polishing the stainless steel surface with a fine abrasive material. It creates a subtle, linear pattern with a matte appearance, commonly used for architectural accents, appliances, and decorative items. These are just some of the most common surface finishes available for stainless steel sheets. The choice of finish will depend on the desired aesthetics, functionality, and application requirements.

- Q:What is the cost of stainless steel sheets?

- The cost of stainless steel sheets can vary depending on several factors such as the thickness, size, and grade of stainless steel being used. Generally, stainless steel sheets are priced per square foot or per square meter. The price range can also depend on the supplier, location, and market conditions. Additionally, any additional processing or finishing required, such as polishing or cutting, can also affect the cost. It is recommended to contact a local supplier or distributor to get accurate and up-to-date pricing information for stainless steel sheets.

- Q:What is the water resistance of stainless steel sheets?

- The water resistance of stainless steel sheets is typically high due to their nonporous nature and corrosion-resistant properties.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Price of 1kg 304 price Stainless Steel Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords