Price hot dipped galvanized steel coil SS GRADE550

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50342 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

Standard and Grade :

Hot-dip galvanized steel coils | ||||

ASTM A653M-06a | EN10327:2004/ 10326:2004 | JISG 3302-2010 | AS-NZS 4534-2006 | |

Commercial quality | CS | DX51D+Z | SGCC | G1+Z |

Structure steel | SS GRADE 230 | S220GD+Z | SGC340 | G250+Z |

SS GRADE 255 | S250GD+Z | SGC400 | G330+Z | |

SS GRADE 275 | S280GD+Z | SGC440 | G350+Z | |

SS GRADE 340 | S320GD+Z | SGC490 | G450+Z | |

SS GRADE550 | S350GD+Z | SGC570 | G550+Z | |

S550GD+Z | G550+Z | |||

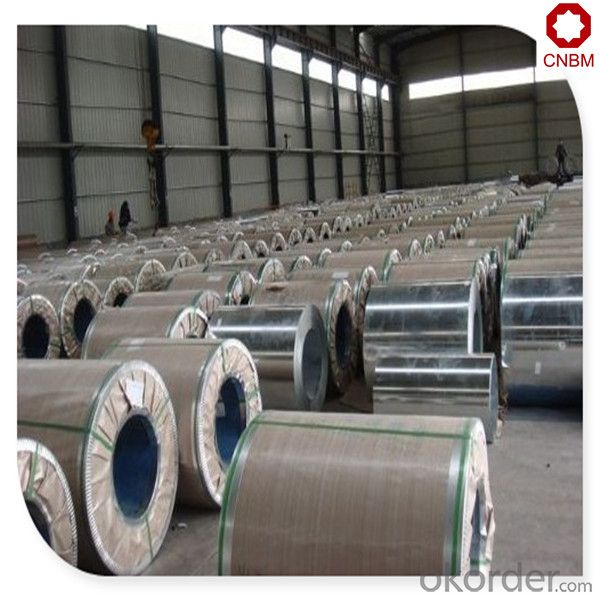

Pictures for stainless steel coil :

FAQ

Q: How do you guarantee the quality of your product?

A: Every process will be checked by responsible QC which insures every product's quality.

Q: How much is your delivery time?

A: Normally within 30 days of receipt of LC original or prepayment, but mostly according to the specific requirements or the quantity

Q: I need sample, could you support?

A: We can supply you with the sample for free, but the delivery charges will be covered by our customers. For avoiding the misunderstanding, it is appreciated if you can provide the International Express Account for Freight Collect. Also you can have a visit to us, welcome to CNBM!

- Q:How are steel coils used in the manufacturing of storage tanks?

- Steel coils are used in the manufacturing of storage tanks as they are rolled into cylindrical shapes and welded together to form the tank's body. The coils provide strength and durability to the structure, ensuring the tank can withstand the pressure and weight of stored materials.

- Q:What are the different methods of engraving steel coils?

- There are several different methods of engraving steel coils, each with its own advantages and applications. Some of the most common methods include: 1. Chemical Etching: This is a process that involves applying a chemical solution to the surface of the steel coil, which selectively removes the metal to create the desired design. Chemical etching is highly precise and can produce intricate patterns and fine details. It is commonly used for decorative purposes, such as creating logos or patterns on steel coils. 2. Laser Engraving: Laser engraving uses a high-powered laser beam to remove the top layer of the steel coil, creating a permanent mark. This method offers high precision and allows for the engraving of complex designs, logos, or text. Laser engraving is frequently used for branding purposes or to add identification marks to steel coils. 3. Mechanical Engraving: Mechanical engraving involves the use of a cutting tool or a diamond-tipped stylus to physically remove the metal from the steel coil's surface. This method is known for its durability and versatility, as it can create deep and long-lasting engravings. Mechanical engraving is often used for industrial applications, such as adding serial numbers, part codes, or other identification marks to steel coils. 4. Electrochemical Etching: Electrochemical etching, also known as electrolytic etching, utilizes an electric current to selectively dissolve the metal surface of the steel coil. This technique is commonly used for marking and branding purposes, as it can produce high-quality, permanent engravings. Electrochemical etching is often employed in industries where precision and durability are essential, such as aerospace or automotive manufacturing. 5. Inkjet Printing: While not strictly engraving, inkjet printing is a method that can be used to add patterns or designs onto steel coils. This process involves using specialized inks and a digital printing system to apply the desired design directly onto the surface of the coil. Inkjet printing is versatile, cost-effective, and allows for high-resolution prints, making it suitable for various applications, including decorative or branding purposes. In conclusion, the different methods of engraving steel coils offer a range of options for creating permanent markings, logos, or patterns. The choice of method depends on factors such as the desired level of precision, durability requirements, and the specific application for the steel coil.

- Q:How are steel coils used in the manufacturing of automotive exhaust systems?

- Steel coils are used in the manufacturing of automotive exhaust systems as they are formed into specific shapes and sizes to create the necessary components, such as pipes, mufflers, and catalytic converters. The coils are precision-cut, welded, and bent to fit the design requirements and ensure efficient exhaust flow, durability, and resistance to high temperatures and corrosion.

- Q:How are steel coils used in the manufacturing of HVAC systems?

- Steel coils are used in the manufacturing of HVAC systems as they serve as the primary heat transfer component. The coils are designed to efficiently transfer heat between the air and refrigerant, allowing for effective cooling or heating of the space.

- Q:2 refridgerator of similar model and same brand..one is stainless steel...the other is clear steel (cheaper)..so wat's the difference between the two?

- Stainless steel is different than regular (clear?) steel because is is an alloy, or combination, of steel and other elements. Stainles steel has 15% chromium, which is very resistant to rust than regular steel. That is why stainless is more expensive

- Q:i need working shoes for women that have steel toe shoes? What store do they sell them in . i live in c.a.

- Do a search for local safety toe shoes. I have to have them for work also, and as a woman I can't just go to Walmarts. Unfortunately the store I go to is here in Atlanta, so not much help. But there are specialty stores for safety shoes. Brands I like are Hytest and Georgia Boots. Especially the Hytest instead of steel toes which are heavy the toes are kevlar.

- Q:I have good quality knives that I sharpen with various things, but mostly with a fine, diamond encrusted dry stone (eze lap) . When I run them over the steel, it doesn't seem to make any difference. I've heard that it aligns the edge, whatever that means. Using a steel, is it all just for show ?

- Very okorder

- Q:How are steel coils coated for color and aesthetics?

- Color and aesthetics can be added to steel coils through a process known as coil coating. This process involves applying a layer of paint or coating material to the surface of the steel coil in order to enhance its appearance and protect it against corrosion. To start the coil coating process, the steel surface is thoroughly cleaned and pre-treated. This step ensures that the surface is free from any contaminants and provides a suitable base for the coating to adhere to. The pre-treatment process may include cleaning, degreasing, and chemical treatment to improve the adhesion and durability of the coating. Once the surface is prepared, the coil is fed through a continuous coating line. In this line, the coating material, usually a liquid paint, is applied to both sides of the steel coil using various methods such as roll coating, spray coating, or electrostatic coating. The coating material is carefully chosen to achieve the desired color, texture, and durability. After the coating is applied, the coil undergoes a curing process. During this process, the coil is heated to allow the coating material to dry and bond to the steel surface. This ensures a strong and long-lasting finish that can withstand exposure to different environmental conditions. Moreover, coil coating technology allows for additional treatments to enhance the aesthetics of the steel coil. For instance, the coil can undergo embossing, where a pattern is pressed onto the surface, creating a textured or three-dimensional appearance. Additionally, other decorative techniques like printing, laminating, or adding metallic effects can be used to achieve specific aesthetic effects. In conclusion, the coil coating process not only adds color and aesthetics to steel coils but also provides a protective layer that increases their lifespan and resistance to corrosion. This makes them suitable for a wide range of applications, including roofing, automotive parts, appliances, and construction materials.

- Q:How are steel coils used in the manufacturing of industrial boilers?

- Steel coils are used in the manufacturing of industrial boilers as they provide a strong and durable material for constructing the boiler's shell and tubes. The coils are shaped and welded together to form the boiler's structure, ensuring a sturdy and reliable construction. Additionally, the steel coils are often coated or treated to resist corrosion and withstand high temperature and pressure conditions, making them suitable for the demanding environment of industrial boiler operations.

- Q:I feel really stupid asking this question but i feel like a put metal/steel strings on my classical guitar how do you tell the difference?

- Nylon strings are made of nylon; steel strings are made of .... if you put steel strings on your nylon string (classical style) guitar, you will destroy it. The instrument cannot stand up under the tension required for the strings, they will not fit in the saddle properly, they will cut the nut, and your machine heads may break. ... now if you're asking about the three lowest strings, those are metal wound around nylon on a nylon string guitar.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Price hot dipped galvanized steel coil SS GRADE550

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50342 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords