PRESSED WIRE ROPE SLINGS (FIBER CORE)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Overview of the pressed wire rope sling

Pressed Steel Wire Rope Sling is made by using the best high quality steel wire rope and produced with the most professional equipments and technics.It is processed by the steel wire rope pressing sleeve machine. The sling is widely used in the field of machinery, metallurgy, construction, shipping, bridge project, gymnasium, oil field, fishing, drilling, colliery and ports etc.

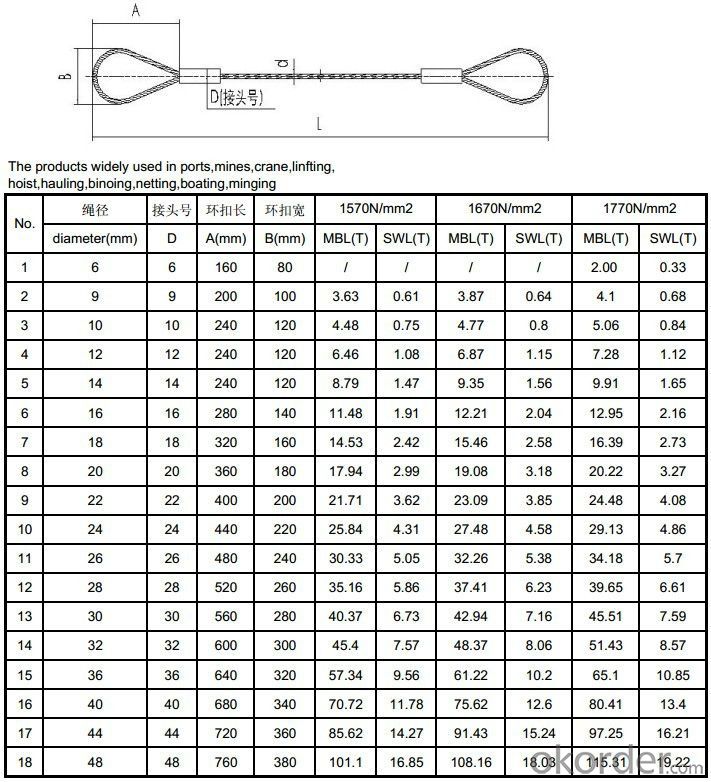

Technical Data

Advantages

1.high strength,

2.light self weight,

3.being steady at work,

4.being not easily broken suddenly and so on

Processing modes

Press the end or both ends to be rings.

It can be combined as sing leg sing ,two-leg sling, tree-leg sling, four-leg sling or more.

How to use

You can choose the wire rope sling made of galvanized steel wire rope to enhance the anti-rust capability.

Besides the abrasion of the outer layer,, it will be broken gradually as the metal fatigue caused by repeated bending when it bypasses the hook and the lifted goods, so the ratio between the hook or the lifted good and the diameter of the steel wire rope decides the service life of the steel wire rope sling.

The pressed wire rope sling is mainly used in transportation which need high strength sling.

Forbidden to stay below the lifted goods or across the goods when working.

FAQ

Q: How’s your service?

A:1. Offer customers 24/7 service, whenever you need us, we are always here for you.

2. Immediate response. Your any inquiry will be replied within 24 hours.

3. Support small order quantity, for the first time cooperation customers, we can send you less quantity for trial order.

4. Support third party inspection company to inspect and check the quality and quantity before delivery.

Picture

- Q:What are the key characteristics of stainless steel?

- The key characteristics of stainless steel are its high corrosion resistance, durability, strength, and ability to maintain its appearance over time. It is also known for its low maintenance needs, heat resistance, and wide range of applications in various industries.

- Q:What is the impact of steel production on the environment?

- Steel production has a significant impact on the environment due to its resource-intensive nature and high carbon emissions. The extraction of raw materials, such as iron ore and coal, leads to habitat destruction and air and water pollution. The traditional blast furnace method emits a substantial amount of greenhouse gases, contributing to climate change. Additionally, the production process generates waste, including slag and emissions of toxic substances. However, advancements in technology, such as recycling and cleaner production methods, offer potential solutions to mitigate these environmental impacts.

- Q:What are the different types of steel tanks and their applications in the food processing industry?

- There are several types of steel tanks used in the food processing industry. Some common ones include stainless steel tanks, carbon steel tanks, and alloy steel tanks. Stainless steel tanks are highly preferred due to their corrosion resistance and hygienic properties. They are suitable for storing and processing various food products such as dairy, beverages, and sauces. Carbon steel tanks, on the other hand, are cost-effective and durable but require proper coating to prevent corrosion. They are commonly used for bulk storage of dry food ingredients like grains, flour, and sugar. Alloy steel tanks offer enhanced strength and resistance to high temperatures. They are often utilized in food processing operations that involve heat treatment, such as cooking, sterilization, and pasteurization. Overall, the choice of steel tank depends on the specific requirements of the food processing industry, including the type of food being processed, storage capacity, and the necessary sanitary standards.

- Q:How are steel plates used in shipbuilding?

- Steel plates are used in shipbuilding to construct the hull and structural components of a ship. These plates are welded together to form the main framework of the vessel, providing strength, stability, and durability. Additionally, steel plates are used to create bulkheads, decks, and compartments, helping to compartmentalize the ship and enhance its safety and buoyancy.

- Q:What are the uses of steel mesh in construction?

- Steel mesh is widely used in construction for various purposes. It is primarily used as reinforcement in concrete structures to improve their strength and durability. Steel mesh provides reinforcement by distributing the load across a larger area and preventing cracks from forming in the concrete. Additionally, it helps to control shrinkage and thermal expansion, enhancing the overall stability of the structure. Steel mesh is also used for fencing and barriers, providing security and protection in construction sites and other areas. Overall, steel mesh plays a crucial role in construction by enhancing the structural integrity and safety of buildings and infrastructure.

- Q:What are the different types of steel bars and rods available?

- There are various types of steel bars and rods available, including mild steel bars, deformed steel bars, stainless steel bars, alloy steel bars, and carbon steel rods. These different types of steel bars and rods have specific properties and are used for various applications in construction, manufacturing, and engineering industries.

- Q:What are the applications of steel wire mesh in agricultural fencing?

- Steel wire mesh is commonly used in agricultural fencing due to its durability and strength. It provides effective containment for livestock, keeping them safe and secure within designated areas. Additionally, steel wire mesh acts as a barrier, preventing unauthorized entry of pests and predators, thereby protecting crops and livestock. It can also be used to create enclosures for poultry, rabbits, and other animals, allowing for efficient management and control. Overall, the applications of steel wire mesh in agricultural fencing are essential for maintaining the integrity and productivity of agricultural operations.

- Q:How is steel tubing used in hydraulic systems?

- Steel tubing is commonly used in hydraulic systems to transmit fluid power by providing a rigid and reliable conduit for the hydraulic fluid. It is used to connect various components in the system, such as pumps, valves, cylinders, and motors, ensuring efficient transfer of hydraulic energy. Steel tubing's high strength, durability, and resistance to pressure and impact make it ideal for handling the high pressures and demanding operating conditions of hydraulic systems.

- Q:What are the different types of steel products used in the manufacturing of gardening tools?

- Some of the different types of steel products used in the manufacturing of gardening tools include stainless steel, carbon steel, and alloy steel. Stainless steel is commonly used for its corrosion resistance and durability, making it suitable for tools exposed to moisture and outdoor conditions. Carbon steel is known for its strength and toughness, making it suitable for heavy-duty tools that require sharp edges, such as pruning shears or hedge trimmers. Alloy steel, a combination of different metals, offers a balance between strength, durability, and affordability, making it a popular choice for various gardening tools like shovels, rakes, and hoes.

- Q:How is steel used in the production of storage tanks and containers?

- Steel is commonly used in the production of storage tanks and containers due to its strength, durability, and resistance to corrosion. It is used to construct the shells and structural components of the tanks, providing a reliable and long-lasting solution for storing various liquids and gases. Additionally, steel can be easily fabricated and welded, allowing for customization and efficient manufacturing processes.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PRESSED WIRE ROPE SLINGS (FIBER CORE)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords