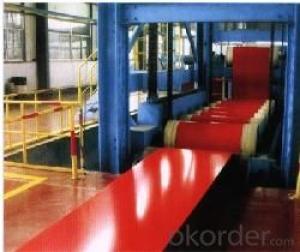

Prepainted Steel Coil/PPGI/PPGI Color Coated Galvanized Steel Sheet With Excellent Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI,ASTM,DIN,JIS | Grade: | steel | Thickness: | 0.17-1.5mm |

| Place of Origin: | China (Mainland) | Brand Name: | CNBM | Model Number: | SGCC Q195L, Q235, DX51D |

| Type: | Steel Coil | Technique: | Hot Rolled,hot dip | Surface Treatment: | Coated |

| Application: | Flange Plate | Special Use: | Steel | Width: | 600-1250mm |

| Length: | 2000-6000mm |

Specifications

1.reasonable price

2.reliable quality

3.fast shipment

4.huge production capacity

5.BV,SGS and TUV certificates

| Commodity | Prepanited steel coil |

| Grade | JIS G3302(SGCC), DX51D, EN10142, GB/T2518-2004, ASTM 653 |

| Standard | ASTM, AISI, DIN, GB |

| Types | Commercial / Drawing / Deep Drawing / Structural quality |

| Width | 500/650/726/820/914/1000/1200/1219/1220/1250mm |

| Thickness | 0.16-1.2mm (0.14-0.5mm is the most advantage thickness) |

| Type of coating | Galvanized |

| Zinc / PE coating | Z60-275g/m2 ,12-20μm(top)/7-10μm(bottom) |

| Surface | RAL System as per customers request |

| ID coil | 508mm |

| Coil weight | 4-6MT |

| Package | Properly packed for ocean freight exportation |

| Application | Industrial panels, roofing and siding for painting |

| Payment terms | 30%TT in advance+70% TT or irrevocable 100%L/C at sight |

| Delivery time | 25 days after recepit of 30% TT or L/C |

PACKING

4 eye bands and 4 circumferential bands in steel, galvanized metal fluted rings on inner and outer edges, galvanized metal & waterproof paper wall protection disk, galvanized metal & waterproof paper around circumference and bore protection

FAQ

We have organized several common questions for our clients,may help you sincerely:

1)How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2)How long can we receive the product after purchase?

In the purchase of product within 20-25 days, we will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 30 days can be served.

3)Do you have necessary certificate or inspection to make sure we can import smoothly?

Syringes are CE,FDA approved. And we supplied main nations in the world.

- Q:How do steel coils contribute to energy efficiency in buildings?

- Steel coils contribute to energy efficiency in buildings in several ways. Firstly, steel coils are used in the construction of insulated panels and roofs, which provide effective thermal insulation. This insulation helps to reduce heat transfer, keeping the interior of the building cool in hot weather and warm in cold weather. Additionally, steel coils are often used in the manufacturing of energy-efficient windows and doors. These windows and doors are designed to minimize heat loss or gain, thereby reducing the need for heating or cooling systems and saving energy. Furthermore, steel coils are also utilized in the production of energy-efficient appliances, such as refrigerators and air conditioners, which consume less electricity while providing the same level of performance. Overall, the use of steel coils in building construction and appliances contributes to improved energy efficiency, reducing energy consumption and promoting sustainability.

- Q:How are steel coils used in the production of kitchenware?

- Steel coils are used in the production of kitchenware by being shaped and formed into various utensils and appliances such as pots, pans, knives, and cutlery. The coils are typically cut, stamped, and pressed into the desired shape, then undergo further processes like polishing, coating, and finishing before being assembled into the final kitchenware products.

- Q:I thought it was STAINLESS STEEL! I have stainless steel can openers spatulas that are rusty. What's up with that? did you know that braces on people's teeth are made of stainless steel? That's why they call people metal-mouth. I used to have braces.

- the stainless steel has some chemicals that it will react however most house hold use will not result in rust

- Q:I know the law regarding selling steel core ammo, but is it possible to buy a steel core bullet and load it yourself?

- Please okorder / You're likely to find steel core ammunition from any of those manufacturers, and many more. Have fun... but steel core ammo is no more effective than lead ammunition, unless you're planning a crime spree and want to attempt to punch through a ballistic vest, and even that's not guaranteed.

- Q:I've seen on TV that stainless steel laminate sheets can be purchased and and used to cover appliances to give it a faux stainless steel look. They mentioned it was important to not have any bubbles (of course) and to work slowly. It's easy to do on a dishwasher, but what about the fridge? The handles are in the way? Do you have to take the handles off? Can anyone find a tutorial for me?

- There okorder appliance paint 2. What you are referring to really is not laminate steel sheets, it's actually more along the lines of shelf liner paper looks like steel with sticky back film that you peel and stick. Place against product and begin to peel down slowly using squeegee or credit card to smooth out bubbles.Sheets can be purchased rangingin size on OKorder for $9.99 + dependent on size. Called stainless steel appliance film can buy a roll for $60.00 on OKorder (normally sells for $100.00) one roll will cover 3 average sized kitchen appliances. Hope this helps!

- Q:How are steel coils used in the production of steel doors?

- Steel coils are used in the production of steel doors as they provide the raw material required for the door manufacturing process. These coils are unwound and then cut into specific lengths to form the door panels. The steel coils are further processed through various steps, such as rolling, pressing, and shaping, to give the door its desired structure and design. Thus, steel coils serve as the foundation for creating sturdy and durable steel doors.

- Q:What are the different types of steel coil slitting lines?

- There are several different types of steel coil slitting lines, including rotary shear slitting lines, loop slitting lines, and drag tension slitting lines.

- Q:How are steel coils used in the manufacturing of machinery?

- Steel coils are commonly used in the manufacturing of machinery as they provide a versatile and reliable raw material. These coils are processed and shaped into various components, such as gears, shafts, and frames, that are essential for the functioning of machinery. The strength and durability of steel make it an ideal choice for withstanding heavy loads and high temperatures, ensuring the longevity and efficiency of machinery in different industries.

- Q:Is Stainless steel called that because.....a. Its stains lessORb. Its virtually stainless (it can't stain).Lol do you know the correct answer?????

- Stainless Steel is named that because when compared to untreated steel it is virtually stainless. It is virtually stainless, and harbors very little germs and bacteria. That is why it has been the standard in the food industry for years.

- Q:What is the process of galvanizing steel coils?

- The process of galvanizing steel coils involves several steps to enhance their durability and protect them from corrosion. Firstly, the steel coils are cleaned thoroughly to remove any dirt, oil, or other impurities that may be present on the surface. This is done through an acid pickling process, where the coils are immersed in a bath of diluted acid solution or treated with a chemical cleaner. This step ensures that the surface of the coils is free from any contaminants, allowing for better adhesion of the zinc coating. After the cleaning process, the coils are rinsed to remove any remaining acid or cleaner. This is crucial to prevent any adverse reactions with the next step of the process. The next step is the actual galvanization, where the cleaned coils are dipped into a bath of molten zinc. The coils are carefully passed through the zinc bath using rollers or other mechanisms to ensure that the entire surface is coated evenly. The zinc bath is maintained at a specific temperature, typically around 450°C (842°F), which allows the molten zinc to bond with the steel surface. As the coils are withdrawn from the zinc bath, excess zinc is removed by passing them through air knives or by centrifugal spinning. This helps to control the thickness of the zinc coating and ensure a uniform appearance. Once the galvanization process is complete, the steel coils are cooled down gradually to room temperature. This allows the zinc coating to solidify and bond firmly with the steel surface, creating a protective barrier against corrosion. The final step in the process is inspection and quality control. The galvanized steel coils are inspected for any defects, such as uneven coating or areas with insufficient zinc coverage. This is usually done visually or through specialized equipment that can detect any anomalies. Additionally, the coating thickness is measured to ensure it meets the required specifications. Overall, the process of galvanizing steel coils is designed to enhance their longevity and protect them from rust and corrosion. By applying a layer of zinc coating to the steel surface, the coils become more resistant to environmental factors, making them suitable for a wide range of applications in various industries.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Prepainted Steel Coil/PPGI/PPGI Color Coated Galvanized Steel Sheet With Excellent Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords