Prepainted Rolled Coil for Construction Roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 25 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

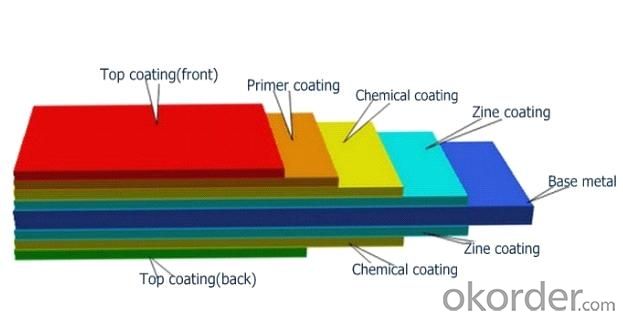

Structure of Prepainted Rolled steel Coil for Construction Roofing

Description of Prepainted Rolled steel Coil for Construction Roofing

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Prepainted Rolled steel Coil for Construction Roofing

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Prepainted Rolled steel Coil for Construction Roofing

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Rolled steel Coil for Construction Roofing

Product | Prepainted Rolled steel Coil for Construction Roofing |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.2-3.0mm |

Width | 600-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ40-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM |

Coil weight | 10MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prepainted Rolled steel Coil for Construction Roofing

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:How do steel coils contribute to energy efficiency in appliances?

- Steel coils contribute to energy efficiency in appliances in several ways. Firstly, steel coils are commonly used in the heat exchangers of appliances such as refrigerators, air conditioners, and water heaters. These coils transfer heat efficiently, allowing appliances to cool or heat the desired space using less energy. By maximizing heat transfer, steel coils help appliances reach the desired temperature faster and maintain it with minimal energy consumption. Secondly, steel coils are often used in the heating elements of appliances like stoves and ovens. These coils provide direct heat to cook or bake food. Steel's excellent thermal conductivity ensures that the heat is evenly distributed, reducing cooking time and energy consumption. This allows appliances to work more efficiently, saving both time and energy. Furthermore, steel coils are durable and long-lasting, which contributes to energy efficiency in appliances. Appliances with steel coils are built to withstand high temperatures and frequent use. This means they require less maintenance and replacement, resulting in fewer resources being used to produce new appliances. By reducing waste and conserving resources, steel coils indirectly contribute to energy efficiency and sustainability. Lastly, steel is a recyclable material. When appliances reach the end of their life cycle, the steel coils can be recycled and used to produce new products. Recycling steel reduces the need for extracting raw materials and saves energy that would otherwise be required in the manufacturing process. This promotes energy efficiency and reduces the environmental impact of appliances. In conclusion, steel coils contribute to energy efficiency in appliances by optimizing heat transfer, reducing cooking time, promoting durability, and facilitating recycling. These factors collectively help appliances operate more efficiently, save energy, and contribute to a more sustainable future.

- Q:How are steel coils used in the manufacturing of automotive parts?

- Steel coils are used in the manufacturing of automotive parts as they are shaped and formed into various components such as body panels, chassis frames, and suspension parts. The coils are processed through a series of steps including cutting, bending, and stamping, to create the desired shape and size for each specific part. These steel components provide strength, durability, and structural integrity to the automobiles, ensuring their safety and performance on the road.

- Q:How do steel coils contribute to energy efficiency in lighting?

- The energy efficiency of lighting relies heavily on the type of light source chosen, such as incandescent, fluorescent, LED, or halogen bulbs. Each of these light sources consumes energy differently. On the other hand, steel coils serve a different purpose in lighting fixtures. Their main function is to provide structural support, dissipate heat, and protect the components. They do not have a direct impact on the energy efficiency of the lighting system. However, steel coils can indirectly improve energy efficiency by offering sturdy support to the fixtures. This ensures that the installations are reliable and long-lasting, reducing the need for frequent maintenance and replacements. A well-supported lighting system guarantees optimal performance and minimizes energy wastage or inefficiencies caused by loose or unstable fixtures. Furthermore, steel coils can also be used to manufacture reflectors or housings for lighting fixtures. These components play a role in enhancing the overall efficiency and distribution of light. By effectively reflecting and directing the light output, energy utilization and illumination can be optimized, resulting in reduced energy waste. Although steel coils themselves do not directly influence the energy efficiency of lighting, their incorporation in the construction and support of lighting fixtures indirectly contributes to a more energy-efficient lighting system.

- Q:How are steel coils used in the manufacturing of roofing materials?

- Steel coils are used in the manufacturing of roofing materials as they are rolled into sheets or formed into various shapes to create durable and long-lasting roofing products. The coils are processed through machines that cut, bend, and shape them into the desired dimensions and profiles required for different types of roofs.

- Q:How are steel coils used in the production of shipping vessels?

- Steel coils are an essential component in the production of shipping vessels. These coils are typically made from high-strength steel, which makes them ideal for constructing the hulls and other structural components of the ships. In the shipbuilding process, the steel coils are first unrolled and cut into specific sizes and shapes according to the ship's design. These pre-cut pieces are then welded or bolted together to form the framework of the vessel. This framework provides the necessary strength and rigidity to withstand the harsh conditions of the sea. Steel coils are also used to manufacture the decks, bulkheads, and other interior components of the shipping vessels. These coils are molded and shaped into various sections that are then assembled and attached to the ship's structure. The use of steel coils in these areas ensures durability and resistance to corrosion, which is crucial for the longevity and safety of the vessel. Furthermore, steel coils are used in the production of ship propellers, rudders, and steering mechanisms. These components are crucial for controlling the direction and movement of the ship. The high-strength steel coils provide the necessary strength and reliability to ensure smooth and efficient navigation. Overall, steel coils play a vital role in the production of shipping vessels by providing strength, durability, and resistance to corrosion. They are used in various parts of the ship's construction, including the hull, decks, bulkheads, and interior components. Without steel coils, the production of shipping vessels would be challenging, and the resulting ships would lack the necessary structural integrity to navigate the seas safely and efficiently.

- Q:The difference between aluminized color steel roll and ordinary color steel roll

- Aluminized color coated sheet is a new type of material produced in China in recent years due to its high end applications. It is often used as an indication of CCLI. It is made of galvanized steel sheet (55% aluminum, 43% zinc and 1.6% silicon), which is more galvanized and more corrosion resistant. It is processed by surface degreasing, phosphating and complexing treatment, and is coated with organic coating.

- Q:Can steel coils be coated with anti-microbial materials?

- Yes, steel coils can be coated with anti-microbial materials to provide protection against the growth of bacteria and other microorganisms.

- Q:How are steel coils used in the production of steel cables?

- Steel coils are used in the production of steel cables by being uncoiled and straightened, then fed into a machine that twists and braids them together to create the cable.

- Q:How are steel coils inspected for impact resistance?

- Steel coils are typically inspected for impact resistance using various methods to ensure their durability and ability to withstand external forces. One common method is the drop test, where a steel coil is dropped from a specified height onto a hard surface. This test simulates the impact that the coil may encounter during transportation or handling. During the drop test, the coil is visually inspected for any visible signs of damage, such as dents, cracks, or deformations. Additionally, the coil may undergo further examinations, such as ultrasonic testing or magnetic particle inspection, to detect any hidden internal defects that could compromise its impact resistance. Another method used to inspect steel coils for impact resistance is the pendulum test. In this test, a pendulum with a known weight and height is swung and impacts the coil's surface. The energy absorbed by the coil during the impact is measured, and this data is used to evaluate its resistance to impact. Furthermore, steel coils may undergo laboratory tests, such as Charpy impact testing, to determine their resistance to sudden impacts. This test involves striking a notched sample of the coil with a pendulum hammer, measuring the amount of energy absorbed by the sample, and evaluating its impact strength. Overall, a combination of drop tests, visual inspections, non-destructive testing methods, pendulum tests, and laboratory tests are used to inspect steel coils for impact resistance. These inspections ensure that the coils meet the required standards and can withstand the potential challenges they may encounter during transportation, storage, and use.

- Q:i wanna buy a sharp carbon steel sword the swords i want are a 200 layer carbon steel katana or a hand forged high carbon steel katanna or a hand sharpened sword which one would be sharper/stronger

- You need to be very careful when selecting a sword. Most f the sellers are lying about their swords. If we were talking about tow 400 year old swords you could bet that the folded steel blade would be the better. Today many rip-off sellers put that in the advertisement to get people that don;t know any better to buy their sword. Many new swords that are not folded are as good or better then folded. your best bet is to buy only from a reputable seller. There are two I know sell good swords Bugei Trading and Cheness. I like cheness because the swords are reasonable in price and very well made. Expect to spend at least $220 to get anything worth buying. Cheness has a line of swords Katana that are made of spring steel. Note: carbon steel varies greatly depending on the exact steel used, it carbon content (how much carbon), and how the sword is made and tempered. Many of the rip-off swords are made of carbon steel, just low quality steel and bad workmanship. ...

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Prepainted Rolled Coil for Construction Roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 25 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords