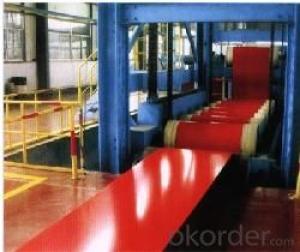

Prepainted Galvanized Steel Coil RAL COLOR

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI,BS,GB,JIS,GB/T 13912-2002 | Grade: | CGCC | Thickness: | 0.15-0.8mm |

| Place of Origin: | Jiangsu China (Mainland) | Brand Name: | Type: | Steel Plate | |

| Technique: | Hot Rolled | Surface Treatment: | Galvanized | Application: | construction industry; automobile making |

| Special Use: | High-strength Steel Plate | Width: | 0.15-0.8mm | Length: | On Request |

| Color: | On Request | Certificate: | ISO9001TUV | Zinc Coating: | Z60-Z150 or on request |

| Payment: | L/C T/T | Usage: | Buldings | Package: | Standard Export Packing |

| Type of Company: | Manufacturer | MOQ: | 25 Tons | Coil weight: | 3-8MT |

Packaging & Delivery

| Packaging Detail: | Standard Export Packing for the goods pallet packing or according to customer's request |

| Delivery Detail: | within 15-45 days after the receipt of L/C or deposit |

Specifications

Thickness: 0.15-0.8mm

Width: 700-1250mm

Length: On Request

Product Description

Prepainted Galvanised Steel Sheet

Thickness: 0.15-1.5mm

Width: 700-1250mm

Length: As your request

Zinc Coating: 60-150g/ m² or as your request

Advantage:

| HIGH QUALITY |

| LOW PRICE |

| FAST DELIVERY |

Application:

1.Buildings and constructions: roofing, ceilings, gutters, venting lines, indoor decorations, window frames, etc

2.Electrical appliances: computer shells, washing machines, refrigerators, dehumidifiers, video recorders, water heaters, etc.

3. Agricultural equipments: troughs, feeding tools, agricultural driers, irrigation channels, etc.

4. Vehicle parts: back-seat plates of buses and trucks, conveying systems, oil tanks, etc.

- Q:I really need help what is the origon of stainless steel?

- Source Of Stainless Steel

- Q:What are the environmental impacts of producing steel coils?

- The production of steel coils has numerous environmental effects. Firstly, it entails the extraction of iron ore, which necessitates mining activities. These mining operations can result in deforestation, habitat destruction, and soil erosion. Furthermore, considerable amounts of energy are required for the extraction and processing of iron ore, contributing to greenhouse gas emissions and air pollution. Moreover, the production of steel coils involves various stages, including smelting and refining, which are energy-intensive and release significant quantities of carbon dioxide, sulfur dioxide, and nitrogen oxides. These emissions contribute to air pollution, acid rain, and climate change. Water consumption is also a noteworthy environmental impact. Steel production necessitates substantial volumes of water for cooling and processing purposes. This high demand for water can strain local water resources and potentially lead to water scarcity or pollution if not managed properly. Furthermore, the steel industry generates substantial quantities of waste and by-products, such as slag, dust, and sludge. Proper disposal and treatment of these waste materials are crucial to prevent soil and water contamination. Lastly, transportation plays a role in the environmental impact of steel coil production. The transportation of raw materials and finished products can result in carbon emissions and air pollution, particularly for long distances. To mitigate these environmental impacts, various measures can be implemented. Adopting more efficient production processes, such as recycling and utilizing renewable energy sources, can reduce energy consumption and emissions. Additionally, enhancing waste management practices, investing in water conservation technologies, and optimizing transportation logistics can help minimize the environmental footprint of steel coil production.

- Q:How do steel coils contribute to the automotive aftermarket?

- Steel coils contribute to the automotive aftermarket by serving as a crucial raw material for manufacturing various components used in vehicles. These coils are responsible for providing strength, durability, and structural integrity to parts like body panels, chassis components, suspension systems, and exhaust systems. Additionally, steel coils are also used in the production of aftermarket accessories such as bumpers, grilles, and custom body kits. Their availability and versatility make steel coils an essential resource for the automotive industry, enabling the production of high-quality aftermarket products that enhance the performance and aesthetics of vehicles.

- Q:which pokemon has the most steel pokemon???

- Transformers.

- Q:What are the different types of steel coil cutting processes?

- There are several different types of steel coil cutting processes, including shearing, slitting, and laser cutting.

- Q:what does steel have inside of it that makes it rust.I need the answer fast!!!!!!!!!

- Steel is made by refining iron. Iron is mined as a red powdery ore. Unfortunately, when moisture and oxygen are present, the steel attempts to revert to its original state.

- Q:Can steel coils be welded together?

- Yes, steel coils can be welded together. Welding is a common technique used to join metals, including steel coils. It involves melting the edges of the coils and fusing them together using a filler material. This process creates a strong and durable bond between the coils, allowing them to be joined and used as a single unit. Welding steel coils together is commonly done in various industries, such as manufacturing, construction, and automotive, to create larger structures or components. However, it is important to ensure proper welding techniques and quality control measures are followed to ensure the integrity and strength of the weld joint.

- Q:How are steel coils processed for edge conditioning or slitting?

- Steel coils are processed for edge conditioning or slitting through a series of steps. First, the coils are inspected for any defects or irregularities. Then, the coils are uncoiled and leveled to ensure a flat surface. After that, the edges are trimmed or conditioned to remove any imperfections. Finally, the coils are slit into narrower strips according to the desired width.

- Q:I want to replace the old refrigator within the next 6 months........ Is the trend to buy a stainless steel refrigerator? Some magazines and internet sites are pointing me that direction. What are the pro's and con's ? I like the color bisque, or cream-color as well, or better, than stainless steel. What would be the reasons to buy stainless steel...is it becoming the most popular color ?

- It's not about color necessarily. Stainless steel is easier to clean and for the most part scratch resistant. It's easier to take care of.

- Q:They both sell the same thingIf prices are to high companies won't by the steelIf prices are to low then the steel company won't earn enoughWhy are some steel companies more successful than others

- Steel is a global commodity. There is some variety in product (flat rolled, tubing, etc), but basically the same product worldwide. Cost to the customer includes shipping of a very heavy product. Inputs are also heavy and costly to ship. Inputs: - Coal - Iron Ore. Some firms have the ability to recycle old steel, a competitive advantage. - Energy (very energy intensive industry) - Labor - Machinery. A new blast furnace is more efficient than 50 years old. So the most profitable steel firms have some of these characteristics: - Proximity to raw materials - Proximity to customers - Access to cheaper means of transportation; rail and sea - Newer machinery - Cheaper labor force - Reasonable cost for electricity and fuel for furnaces

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Prepainted Galvanized Steel Coil RAL COLOR

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords