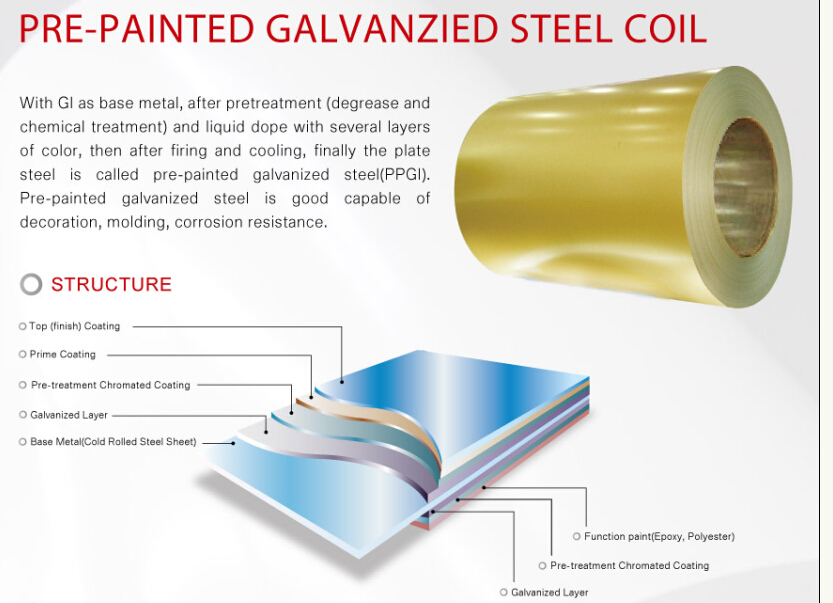

Prepainted galvanized steel coil PPGI PPGL COATED STEEL

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PREPAINTED GALVANIZED STEEL COILS

ZINC COATING:60g/m2 (-/+10g/m2)

COLOR: ACCORDING TO COLOR SAMPLE.

TOP COATING:5+13 MICRON, BACK COATING:5-7 MICRON;

COIL WEIGHT:3-5 ton

STANDARD:JIS G 3312

STEEL GRADE:CGCC

COIL ID:508mm

1.THICKNESS:-0.02/+0.02mm; WIDTH:0/5mm.ZINC COATING:+/-10g/m2;

2.TOLERANCE:+/-10% WITH QUANTITIES AND AMOUNT.

3.PACKAGE:FULL PACKED WITH ANTI-DAMP PAPER,IRON SHEET OUTSIDE.

4.SHIPMENT: GOODS WILL BE DELIVERED WITHIN 20 DAYS AFTER RECEIVING ADVANCE PAYMENT

5.TERMS OF PAYMENT: 20% TT IN ADVANCE,80% AGAINST COPY OF B/L. OR LC AT SIGHT

6.THIRD PARTY INSPECTION: SGS, INTERTEK,COTECNA ,BV. ANY EXPENSE ON INSPECTION(SUCH AS SGS,INTERTEK...) SHALL BE ON BUYER'S ACCOUNT.

- Q:What are the different types of steel coil loading and unloading devices?

- There are several different types of steel coil loading and unloading devices, including coil lifters, coil hooks, coil tongs, coil grabs, coil c-hooks, coil fork attachments, and coil transfer cars. These devices are used to safely and efficiently handle steel coils during transportation and storage processes.

- Q:How are steel coils measured?

- Steel coils are typically measured by their weight, length, width, and thickness. The weight is usually expressed in tons or kilograms, while the dimensions are measured in inches or millimeters.

- Q:What are the common coil tests performed for quality control?

- Some common coil tests performed for quality control include tension tests, bend tests, hardness tests, and dimensional checks. These tests help to ensure that the coils meet the required specifications and are of high quality.

- Q:Can steel coils be coated with magnetic materials?

- Yes, steel coils can be coated with magnetic materials.

- Q:Can steel coils be used in high-temperature applications?

- Yes, steel coils can be used in high-temperature applications. Steel is known for its excellent heat resistance and can withstand elevated temperatures without significant loss of strength or deformation.

- Q:I know that mild steel is more brittle than cast iron....but that is all.......please help??Thank you in advance......Ruby:D

- Mild steel is iron that has had most of the carbon removed in an open hearth furnace or a Bessemer converter. It is mainly the carbon content that makes iron brittle (iron is brittle, not steel).

- Q:What are the different types of steel coil packaging materials used during processing?

- Some of the different types of steel coil packaging materials used during processing include steel strapping, plastic strapping, stretch film, shrink wrap, and coil covers.

- Q:Can steel coils be coated with anti-tampering materials?

- Yes, steel coils can be coated with anti-tampering materials. These materials provide an additional layer of protection against tampering and unauthorized access to the steel coils.

- Q:How are steel coils used in the manufacturing of structural components?

- Steel coils are used in the manufacturing of structural components by being processed through various techniques such as cutting, bending, and welding to form the desired shapes and sizes. These coils serve as the raw material for fabricating beams, columns, and other structural elements used in buildings, bridges, and infrastructure projects. The high strength and durability of steel make it an ideal choice for constructing load-bearing components, ensuring the stability and integrity of the structures.

- Q:I have taylormade burner steel irons and I was wondering what would the flex of steel be if you were to compare it to graphite shafts, like regular, stiff, super stiff, etc...THANKS!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

- If i understand you correctly, i think you misunderstand shafts. Steel shafts vs. graphite shafts these days is more of a competition of weights, not flexibility. Both steel and Graphite have different flex profiles available from Ladies (L) to super stiff (X). Graphite may feel a little more whippy than steel because of the lighter weight. Shafts will vary by company as well. Stiff from True temper may not be as stiff as one from Aldila, or vice verse. You can also make a shaft play stiffer or more flexible by where you cut the length. This is called tipping. Take more from the bottom and it will be stiffer, more from the grip end and it will play more flexible.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Prepainted galvanized steel coil PPGI PPGL COATED STEEL

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords