PREPAINTED GALVANIZED CORRUGATED STEEL SHEET

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PREPAINTED GALVANIZED CORRUGATED STEEL SHEET

1.STEEL GRADE & STANDARD:EN10169 DX51D

2.ZINC COATING MASS:Z60

3.COLOR:RAL CARD

4.TOP COATING: 5+13 MICRONS PE,BACK COATING: 5-7 MICRONS EPOXY

5.PACKAGE WEIGHT:2-3TON

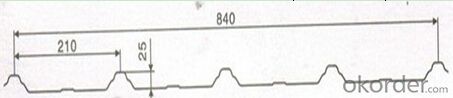

6.0.50MM*840MM*4000MM( AFTER CORRUGATION) THICKNESS:0.2mm-0.8mm.

7.BEFBEFORE CORRUGATION:1000MM

8.TOLERANCE: -/+10% TOLERANCE WITH QTY AND AMOUNT (THICKNESS:-/+0.02mm; WIDTH:0/+5mm; ZINC COATING:-/+10g/m2; COATING MASS THICKNESS:-/+ 2 MICRON)

9.PACKAGE: FULL WRAPPED ANTI-DAMP PAPER INSIDE, AND STEEL SHEET OUTSIDE IN 20'FCL.

10.SHIPMENT:WITHIN 30 DAYS AFTER RECEIPT OF ADVANCED PAYMENT

11.DOCUMENTS REQUIRED: 1, ORIGINAL CLEAN ON BOARD BILL OF LADING;2,ORIGINAL SIGNED COMMERCIAL INVOICE;3,ORIGINAL PACKING LIST ; 4.SGS OR OTHER THIRD PARTY CERTIFICATE.

12.TERMS OF PAYMENT:30% ADVANCED PAYMENT BEFORE PRODUCTION,80% AGAINST BL COPY. OR 100% LC ATSIGHT.

- Q:Are the steel sheets available in different grades?

- Different grades of steel sheets are available. Steel is categorized into various grades depending on its composition, strength, and other properties. These grades encompass carbon steel, stainless steel, alloy steel, and tool steel, among others. Each grade possesses distinct characteristics and is appropriate for different applications. The selection of a grade relies on factors such as the desired strength, resistance to corrosion, and cost-effectiveness for the particular use. Consequently, when buying steel sheets, it is crucial to take into account the grade that most effectively meets the intended purpose.

- Q:Can steel sheets be laminated with other materials?

- Yes, steel sheets can be laminated with other materials. Lamination is a process of bonding two or more materials together to create a composite material with enhanced properties. In the case of steel sheets, they can be laminated with other materials such as plastics, polymers, wood, or even other metals. This process is commonly used to improve the strength, durability, corrosion resistance, or aesthetic appearance of steel sheets. Laminated steel sheets can be found in various industries, including automotive, construction, aerospace, and furniture manufacturing.

- Q:Can steel sheets be used for bulletproof applications?

- Indeed, steel sheets possess the ability to serve in bulletproof capacities. Steel, renowned for its strength and durability, effectively halts bullets from breaching its surface. Industries commonly employ bulletproof steel sheets during the production of armored vehicles, military apparatus, and personal protective equipment, including bulletproof vests and helmets. The bulletproof capabilities of these steel sheets hinge significantly upon their thickness and quality. Manufacturers can tailor the design of steel sheets to withstand an array of ballistic threats, encompassing handguns to high-powered rifles. Moreover, steel's affordability and ease of production render it a favored selection for bulletproof applications across diverse sectors.

- Q:Can steel sheets be used for electrical applications?

- Yes, steel sheets can be used for electrical applications. Steel is a good conductor of electricity and is commonly used in electrical transformers, motors, and other electrical equipment. However, it is important to ensure that the steel sheets are properly insulated to prevent any electrical hazards or short circuits.

- Q:Are steel sheets resistant to extreme weather conditions?

- Yes, steel sheets are generally known for their high resistance to extreme weather conditions. Due to their durable and robust nature, they can withstand harsh temperatures, heavy rain, strong winds, and even hailstorms without significant damage.

- Q:Can the steel sheets be easily formed into cylinders or tubes?

- Yes, steel sheets can be easily formed into cylinders or tubes. This process is commonly known as tube or pipe bending. Steel sheets, typically in the form of flat plates, can be bent using various methods such as roll bending, rotary draw bending, and induction bending. These techniques apply force to the steel sheet to gradually shape it into a cylindrical or tubular form. The flexibility and malleability of steel allow it to be easily molded into different shapes, including cylinders and tubes.

- Q:Can steel sheets be used for acoustic insulation?

- Steel sheets alone cannot provide effective acoustic insulation. Steel is a highly conductive material that allows sound waves to easily pass through, resulting in poor soundproofing properties. To achieve acoustic insulation, additional materials with sound-absorbing properties, such as acoustic foam or mineral wool, should be used in combination with the steel sheets.

- Q:Are steel sheets fire-resistant?

- Yes, steel sheets are generally considered to be fire-resistant. Due to their high melting point and low combustibility, steel sheets can withstand high temperatures and prevent the spread of fire.

- Q:What are the different sheet metal welding techniques for steel sheets?

- There are several sheet metal welding techniques commonly used for steel sheets, including spot welding, seam welding, and TIG welding. Spot welding involves joining two metal sheets by applying pressure and heat at specific points, creating a strong bond. Seam welding, on the other hand, involves continuously welding along the length of a joint, creating a continuous welded seam. TIG welding, also known as tungsten inert gas welding, uses a non-consumable tungsten electrode to create an arc that melts the metal, forming a weld pool that fuses the steel sheets together. Each technique has its own advantages and is chosen based on the specific requirements of the project.

- Q:Are steel sheets resistant to abrasion?

- Yes, steel sheets are resistant to abrasion.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PREPAINTED GALVANIZED CORRUGATED STEEL SHEET

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords