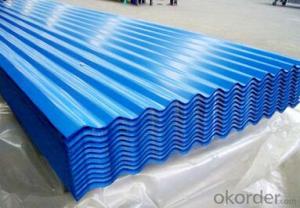

Prepainted Galvanized Corrugated sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre painted Galvanized roofing sheet

1> thickness: 0.12mm - 4.5mm

2> width:762mm/914mm/1200mm

3> length:Any length

4> basic material: galvanized steel sheet, Aluminum steel sheet

5> Zinc (Al) coating: 60g/m2 - 270g/m2

6> shape: corrugated

7> mainly usage: roof.

8> color: RAL card

9> Package: standard export package or as customer's requirement

Full Hard Galvanized Corrugated Steel Sheet / Corrugated Steel Sheet

Certificate | corrugated sheet :ISO9001:2008 |

Standard | corrugated sheet :ASTM A653, JIS G3302 SGCC/SGCH,GB/T2518, European standard |

Grade | corrugated sheet : SGCC, SGCH, SGCD1-SGCD3, SGC340-SGC570, SGCC, DX51D |

Specification | corrugated sheet :(0.12-1.80)mm*1500mm or under |

Type | corrugated sheet :steel coil, steel sheets/ plates, corrugated steel sheets/plates |

Terms of payment | corrugated sheet :T/T or L/C |

Shipment | corrugated sheet : shipped by 20 feet container, loading about 25 tons |

Package: | corrugated sheet : seaworthy standard export package |

- Q:What are the uses of steel sheets?

- Steel sheets have a wide range of uses across various industries, including construction, automotive, manufacturing, and appliances. They are commonly used for roofing, siding, and structural purposes in buildings. Steel sheets are also used in the production of automobiles, ships, and aircraft due to their strength and durability. Additionally, they are utilized as raw materials for manufacturing machinery, appliances, and electrical equipment.

- Q:What is the difference between a galvanized and aluminum steel sheet?

- To protect carbon steel from corrosion, a layer of zinc is applied to create a galvanized steel sheet. This process, called galvanization, involves immersing the steel in molten zinc, which forms a protective coating on the surface. Galvanized steel sheets are highly durable and act as a barrier against moisture, chemicals, and other corrosive elements. They find wide use in construction, automotive, and industrial sectors. Contrarily, aluminum steel sheets are produced from lightweight and corrosion-resistant aluminum. Rolled from aluminum ingots, these sheets come in varying thicknesses. Even without additional coatings or treatments, aluminum sheets offer exceptional resistance to corrosion. They are commonly employed in aerospace, transportation, and architectural applications. When it comes to differences, the key distinction between galvanized and aluminum steel sheets lies in their composition and protective properties. Galvanized steel sheets possess a zinc coating, which provides superior corrosion resistance compared to plain carbon steel. This makes them more suitable for outdoor and high-moisture environments. Moreover, galvanized steel sheets can be easily welded and painted, allowing for greater customization. In contrast, aluminum steel sheets have inherent corrosion resistance due to the presence of aluminum. They are lighter in weight than galvanized steel sheets, making them a preferred choice for applications that prioritize weight reduction. Aluminum sheets also exhibit better thermal conductivity and reflectivity properties, making them ideal for applications that involve heat dissipation or insulation. To summarize, galvanized steel sheets are carbon steel sheets protected by a layer of zinc to enhance corrosion resistance, while aluminum steel sheets are made from aluminum and offer inherent resistance to corrosion. The choice between galvanized and aluminum steel sheets depends on specific application requirements, such as the level of corrosion protection needed, weight considerations, and desired thermal properties.

- Q:What are the different methods of protecting steel sheets from graffiti?

- There are several methods of protecting steel sheets from graffiti, including anti-graffiti coatings, sacrificial coatings, and physical barriers. Anti-graffiti coatings are specially formulated to provide a protective layer over the steel surface, making it easier to remove graffiti without damaging the underlying material. Sacrificial coatings involve applying a removable layer of protective coating that can be easily replaced once graffiti occurs. Physical barriers, such as fences or screens, can also be installed to prevent direct access to the steel sheets, making it harder for graffiti to be applied in the first place.

- Q:Can steel sheets be used for construction purposes?

- Yes, steel sheets can be used for construction purposes. They are commonly used in various construction applications such as roofing, wall cladding, flooring, and structural components due to their durability, strength, and resistance to fire and corrosion.

- Q:Are the steel sheets easy to transport and handle?

- Steel sheets are quite convenient to transport and handle. They are generally lightweight and can be effortlessly piled and loaded onto trucks or containers for transportation. Moreover, steel sheets frequently come in standardized sizes and shapes, which simplifies their manipulation and maneuverability. Nevertheless, it is crucial to acknowledge that the size and thickness of the steel sheets can affect their ease of transportation and handling. Bigger and thicker sheets may necessitate specialized equipment or extra manpower to lift and relocate them.

- Q:Can steel sheets be used for noise barriers?

- Yes, steel sheets can be used for noise barriers. Steel is a durable material that can effectively block sound transmission, making it suitable for creating noise barriers in various environments such as highways, industrial areas, or construction sites. Additionally, steel sheets can be customized and installed in different configurations to enhance their noise-blocking properties.

- Q:How are steel sheets protected during storage in humid environments?

- Corrosion prevention is a common practice used to protect steel sheets stored in humid environments. This involves implementing various measures to minimize the steel sheets' exposure to moisture and humidity, which are the main contributors to corrosion. One effective method is applying a protective coating to the steel sheets. This coating acts as a barrier between the steel and the surrounding moisture, preventing direct contact and reducing the risk of corrosion. Depending on the specific requirements and conditions of the storage environment, different types of coatings, such as paint, oil, or specialized corrosion-resistant coatings, can be used. In addition to protective coatings, steel sheets can also be stored in a controlled environment with regulated temperature and humidity levels. This helps to reduce the amount of moisture in the air surrounding the steel sheets, thereby decreasing the likelihood of corrosion. Dehumidifiers or climate-controlled storage facilities can be utilized to achieve this controlled environment. Proper handling and packaging of the steel sheets also play a crucial role in their protection during storage in humid environments. It is important to store the sheets in a manner that allows for adequate airflow and ventilation to minimize moisture accumulation. Additionally, packaging materials, such as plastic wraps or moisture-resistant packaging materials, can provide an extra layer of protection against moisture. Regular inspection and maintenance are essential to ensure the ongoing protection of steel sheets during storage in humid environments. This includes regularly checking for signs of corrosion or damage and promptly addressing them to prevent further deterioration. In conclusion, a combination of protective coatings, controlled storage environments, proper handling, and regular maintenance are necessary to safeguard steel sheets from the negative effects of humidity and moisture during storage.

- Q:Are steel sheets suitable for modular construction?

- Yes, steel sheets are suitable for modular construction. They are lightweight, durable, and have high strength-to-weight ratio, making them ideal for constructing modular buildings. Steel sheets can be easily fabricated and assembled into modular components, providing flexibility and ease of construction. Additionally, steel is resistant to fire, pests, and weathering, ensuring longevity and safety in modular structures.

- Q:Can steel sheets be used for solar panel mounting structures?

- Yes, steel sheets can be used for solar panel mounting structures. Steel is a commonly used material for solar panel mounts due to its strength, durability, and cost-effectiveness. It provides a sturdy framework to support the weight of the solar panels and withstand various weather conditions. Additionally, steel sheets can be easily fabricated and customized to meet specific project requirements, making them a suitable choice for solar panel mounting structures.

- Q:Can steel sheets be etched or engraved?

- Yes, steel sheets can be etched or engraved using various techniques such as chemical etching, laser engraving, or mechanical engraving.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Prepainted Galvanized Corrugated sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords