Prepainted galvanized corrugated plate / Sheet in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction of Prepainted Galvanized Steel:

Prepainted Galvanized Steel usually refers to have substrate processed with surface processed and coated then(roller coated )or bonded organic thin film and baked, and it is able to be processed to final production .

Prepainted Galvanized Steel qualified with excellent decorative, formability, corrosion resistance, coating adhesion ,can keep for a long time as well as maintain fresh color .For color coated steel sheet can obtain good economic benefit by steel belt wood ,efficient in construction and save energy ,prevent pollution etc. Which is an ideal material; for manufacturing board.

Description of Prepainted Galvanized Steel:

1.material : galvanized steel sheet / prepainted galvanized sheet

2.sheet thickness : normal use 0.3-0.6mm

3.length: any length, according to the transportation, generally less than 12m

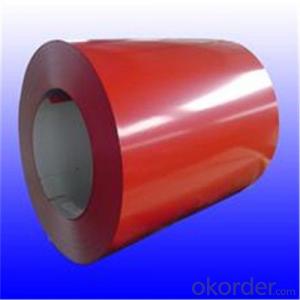

4.color: standard color: red, blue, white, grey; special color: according to RAL color

Specification of Prepainted Galvanized Steel:

prepainted corrugated steel plate | |

material | galvanized steel sheet |

prepainted galvanized sheet | |

model No. | types of roof sheets |

sheet thickness | normal use 0.3-0.6mm |

length | any length, according to the transportation, generally less than 12m |

color | standard color:red, blue, white, grey |

special color: according to RAL color | |

characteristic | 1:weather proof |

2:heating insulation | |

3:fireproof | |

4:anti-rust | |

5:sound insulation | |

6:long life span: more than 15 years | |

advantages | 1.low foundation cost |

2.easy construction | |

3.time saving | |

4.labor saving | |

application field | 1:construction:prefabricated house, steel house, mobile house, modular house, villa, bungalow design, portable house/carbin, ready made house, kiosk booths, steel building... |

2:container manufacturing | |

3:household appliances and furniture | |

4:vehicle and vessel manufacturing | |

5:others,like machinery structual parts, manufacturing shells of motors and so on | |

packing | plastic film, pallet or as your request |

Applications of Prepainted Galvanized Steel

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making steel roofing, insulation panel, corrugate sheet, facade wall, shutters, T-bar and home appliance.

Packaging & Delivery of Prepainted Galvanized Steel

The packing of coils consists of anti-damp paper, PVC film, hardboard paper, steel box, strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye to the side) or wooden pallets(eye to the sky).

Images of Prepainted Galvanized Steel:

FAQ

1.What's your MOQ?

50MT, it is for one container.

2.Whether your company have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the

- Q:Hi! does anyone know where can i find a building with a structure of steel frames, i need to do an analysis for school so i need joint details, girder details and such! PLEASE help me! thanks

- if u need to analyse a steel framed structure for joint details the best example would be of a mechanic workshop...the truss of such a workshop is always supported on a portal frame and in most of the case thats a steel structure...do keenly observe the joints at the footing plates that is connected to the girder section...nd also observe the joints in truss of such a frame....myslf m a civil engg. student.

- Q:Can steel coils be cut?

- Yes, steel coils can be cut.

- Q:I heard that the stores don't sale Steel Legion anymore...Is this true..Also I want to know why they cost more than regular Imperial Guardsmen..Such as Cadian...Do they have something Special?Also what do I need to buy to have a complete Steel Legion army..I need two squads of troops of 20's?and two sergeants for each squad.and one commiser?Well I;m guessing..someone please help...I havent played in about 4 years.

- The stock at various shops may vary, but you can buy Steel Legion miniatures through the mail order, or the Internet from GW. Cadian troopers are plastic, There are no plastic Steel Legion troops. The plastic models are (a tiny bit) not so horribly expensive as the metallic ones. The minimum requirements for your force vary from mission to mission, but a good start is 1 HQ unit 2 Troop choices. Also, the total points cost of the battle is to be considered. (Usually 500, 1000, or 1500 points.) What you described is one possible choice, although the size of IG squads is 10 and not 20. And you must include a command squad, the commissar is optional. You might change the other 20 troops for a tank, or a squad of Sentinels. Happy gaming!

- Q:What is the maximum length of a steel coil?

- The maximum length of a steel coil can vary depending on various factors such as the type of steel, manufacturing capabilities, and transportation logistics. However, in general, steel coils can be several hundred meters long, with some specialty coils exceeding a kilometer in length.

- Q:I have a Nike SQ Sumo 21 degree and it is a steel shaft. I hit the ball very high with this club and I lose distance. I don't hit any of my other clubs high it's just this one. Is it because of the steel shaft or is it the club? Help please.

- Actually it isnt so much whether its steel or graphite, although in the past steel was stiffer as a rule. Today many graphite shafts (depending on the shaft manufacturer) are in fact stiffer then some steel shafts. IE proforce XS vs true temper R You also have to look at the kick point in the shaft. The kick point is where the shaft bends at moment of impact. My shafts are tipped lower because I custom made them that way because I typically hit the ball low to begin with. High kick point means lower ball flight and lower means a higher flight. Also different brands have different stiffness' some regular shafts you'll find feel stiffer then other stiff shafts. the only way to tell if its the shaft is to have all the same shafts installed with the same kickpoint hope this helps

- Q:How are steel coils annealed for improved properties?

- Steel coils are annealed for improved properties by heating them to a specific temperature and then slowly cooling them down. This process, known as annealing, helps to relieve internal stresses in the steel, increase its ductility, and improve its machinability.

- Q:How are steel coils used in the production of packaging machinery?

- Steel coils are used in the production of packaging machinery primarily for the construction of structural components such as frames, supports, and rollers. The high tensile strength and durability of steel coils make them ideal for handling heavy loads and ensuring the stability and longevity of packaging machinery during operation.

- Q:What are the common methods of painting steel coils?

- There are several common methods used for painting steel coils, depending on the specific requirements and desired outcomes. Here are some of the most commonly employed methods: 1. Coil coating: This is the most common method used for painting steel coils. It involves applying a layer of paint on the coil's surface before it is shaped into its final form. The coil is first cleaned and pre-treated with chemicals to ensure proper adhesion of the paint. Then, the paint is applied using various techniques such as roll coating, spray coating, or dip coating. The coil is then cured in an oven to ensure proper drying and adhesion of the paint. 2. Electrostatic painting: This method involves using an electrostatic charge to apply the paint onto the steel coil. The coil is first cleaned and pre-treated, and then an electrostatic charge is applied to the paint particles. The charged particles are attracted to the grounded coil, resulting in an even and efficient paint application. This method is often used for high-performance coatings as it provides excellent coverage and adhesion. 3. Powder coating: Powder coating is a popular method for painting steel coils, especially for applications that require a durable and long-lasting finish. In this method, a dry powder paint is applied to the coil's surface electrostatically. The powder adheres to the coil due to the electrostatic charge, and then the coil is heated in an oven to melt and cure the powder, forming a smooth and protective coating. 4. Spray painting: Spray painting is commonly used for smaller steel coils or touch-up applications. It involves using a spray gun to apply the paint onto the coil's surface. The coil is cleaned and pre-treated, and then the paint is sprayed in a controlled and even manner. This method allows for precise control and customization of the paint application. Overall, the choice of painting method depends on factors such as the desired finish, durability requirements, cost considerations, and the specific application of the steel coil. Each method has its own advantages and limitations, and it is important to select the most suitable method based on the specific needs and constraints of the project.

- Q:How do steel coil manufacturers minimize waste and maximize efficiency?

- Steel coil manufacturers minimize waste and maximize efficiency by implementing various strategies such as optimizing production processes, recycling and reusing scrap materials, adopting advanced technologies for energy conservation, and implementing lean manufacturing principles to eliminate unnecessary steps and reduce downtime. They also focus on continuous improvement, employee training, and regular maintenance of equipment to ensure smooth operations and minimize waste generation.

- Q:I bought my Gerber Scout for 29 bucks at the local Walmart a couple months ago, and so far it's performed better than any of my previous knives (a couple of low quality Bucks, and a Winchester). However, my friend just bought a 50 dollar Buck knife and I absolutely love it, so I'm debating trading mine in and pitching in a bit of cash for the same kind.What troubles me is the fact that everybody seems to be bashing 440A steel. I hear a lot of bad things about it; how it is soft, chips easy, dull quickly, etc. How bad is 440A steel really, and would it be worth trading in my Gerber plus about 30 cash for a Buck Vantage Pro? Apparently the Vantage Pro uses S30V steel, so is it really that big of an upgrade, from 440A to S30V? Thank you.

- 440 steel is fine for most knives, but there are better quality steels out there for specialized uses. If you like the knife you have, don't worry about what other people say. If you like the new knife more, trade for it. Sometimes I question why people have to ask so many questions about what's better than what.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Prepainted galvanized corrugated plate / Sheet in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords