Prepainted Galvanized/Aluzing Steel coils for Roofings

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Details

Basic Info.

Model NO.:G550, FULL HARD, SGHC

Type:Steel Coil

Standard:ASTM, GB, JIS

Certification:ISO, SGS, BV

Surface Treatment:Coated

Technique:Hot Rolled

Special Use:High-strength Steel Plate

Base Metal:Galvanized or Galvalume Steel

Width:914/1000/1200/1219/1220/1250mm

Thickness:0.16-1.2mm

Zinc-Coating:Z50-150G/M2 or Az40-100G/M2

Top Side Painting:15-25 Micron

Back Side Painting:5-8 Micron

Colour:Ral Standard or According to Customers′ Requirment

Coil Weight:3-6 Mt

Coil ID:508/610 Mm

Export Markets:North America, South America, Eastern Europe, Southeast Asia, Africa, Mid East, Eastern Asia

Additional Info.

Packing:Seaworthy Packing

Standard:0.135-1.2MM

Origin:China, Shandong

HS Code:72107000

Production Capacity:180000mt

Product Description:

1. Standard: AISI, ASTM, BS, DIN, GB, JIS, ASTM, JIS, GB

2. Steel Grade: DX51D, SGCC, SGCH, SPCC, SPCD, DC01, ST12, ST13, Q195, 08AL

3. Thickness: 0.13-0.5mm

4. Width: 600-1250mm

5. Length: Up to The Thickness or as require

6. Spangle: Zero, Mini, Regular, Big, Skin Pass

7. Audited Certificates: BV, SGS, ISO, CIQ

8. Zinc Coating: 40g-200g

9. Surface: Chromated, dry/oiled, Cr3 treated anti-finger

10. Package: Standard exporting package (or as required)

11. ID: 508/610mm

Specification:

| commodity | Color Coated Steel Coil (PPGI/ PPGL) |

| Techinical Standard: | JIS G3302-1998, EN10142/10137, ASTM A653 |

| grade | TSGCC, TDX51D / TDX52D / TS250, 280GD |

| Types: | For general / drawing use |

| Base metal | galvanized, galvalume, cold rolled steel |

| Thickness | 0.14-1.0mm(0.16-0.8mm is the most advantage thickness) |

| Width | 610/724/820/914/1000/1200/1219/1220/1250mm |

| Type of coating: | PE, SMP, PVDF |

| Zinc coating | Z60-150g/m2 or AZ40-100g/m2 |

| Top painting: | 5 mic. Primer + 15 mc. R. M. P. |

| Back painting: | 5-7 mic. EP |

| Color: | According to RAL standard |

| ID coil | 508mm / 610mm |

| Coil weight: | 4--8MT |

| Package: | Properly packed for ocean freight exportation in 20' ' containers |

| Application: | Industrial panels, roofing and siding for painting / automobile |

| Price terms | FOB, CFR, CIF |

| Payment terms | 20%TT in advance+80% TT or irrevocable 80%L/C at sight |

| delivery time | 25 days after recepit of 20% TT |

| Remarks | Insurance is all risks |

| MTC 3.1 will be handed on with shipping documents | |

| We accept SGS certificatation test |

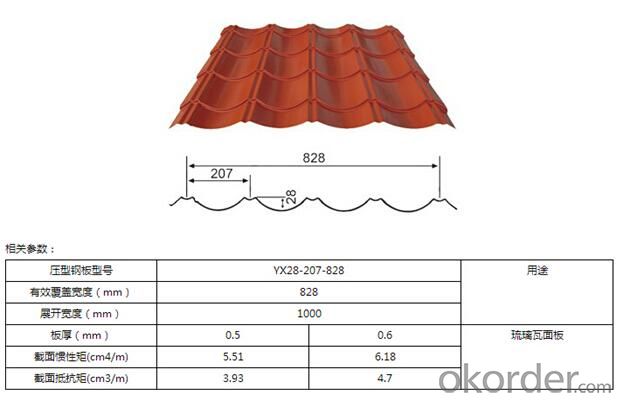

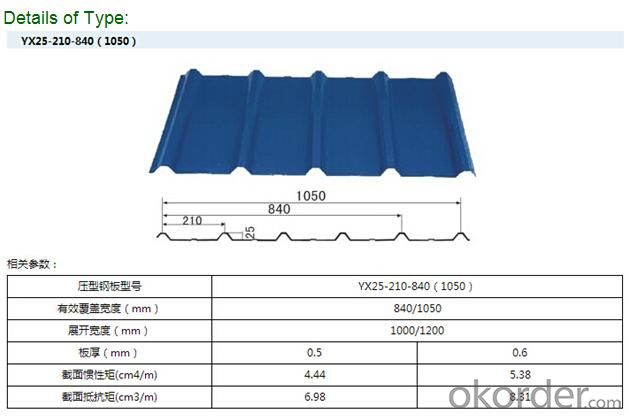

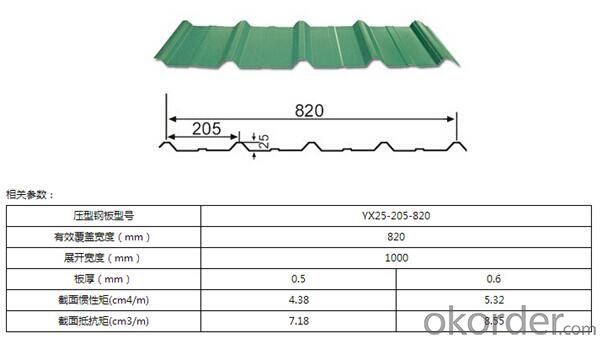

Details of Type:

FAQ:

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

4.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

- Q:I believe steel is stronger but it steel lighter than iron too?

- Steel is iron, with other things added that strengthen it and/or make it less rust liable. So, in general, steel is stronger than iron. In so far as the density, that depends on the steel alloy. Some are higher than iron, some lower. Remember there are hundreds of different steel alloys. edit: but the density is still close to that of iron. density steel 7750 to 8050 kg/m? density iron 7870 kg/m?

- Q:please i need your help in answering this question manufacturing process of steel containers and 20 references

- There are many types of steel containers and many different mnfg processes. There are also thousands of different steel alloys. Steel is used for canned food, compressed air cyclinders, hydraulic pressure vessels, electrical boxes, and many other containers. Steel containers are made out of sheet metal by soldering, brazing, spot welding, seam welding, riveting, bolting, screwing, etc. Heavier wall containers are fabricated of plate steel. Some steel containers are made by deforming the steel by extruding, forging, spin forming, drawing, ironing, etc. Some steel containers are made by machining. You should be able to find plenty of references if you search for these terms. good luck

- Q:I have been thinking of buying a knife that says it has damascus steel. The reason for the question is that many people told me that damascus steel does not exist anymore, and that damascus nowadays is fake. Is this true???

- Well, it depends on what you call fake. Modern Damascus steel is perhaps similar, but it is not what people would call Damascus steel in 1500. It is made to look similar, but structurally it is different. For the most part the specific way of making Damascus steel is lost to history.

- Q:i need some ideas of what material could replace iron or steel to make fridges, stoves, dishwashers, tractors, aircrafts, cars and buses and anything else that is made of iron and steel. anything is greatly appreciated as at the moment i have no idea what to put down.

- Iron and steel has, in lots of cases, been replaced by Aluminium and its alloys. Titanium and composite (Carbon reinforced resin) materials are also used where weight saving and non bending strength is required. Many of these types of materials are expensive and as iron ore is readily available it will be some time before it is replaced on a wide basis. Many other materials are not good where higher temperatures are concerned however there is an increasing use of ceramics being used for say stove tops. Hope this helps.

- Q:what is the densest type of steel ? what is its density ?what is its tensile strength .

- Agree okorder . If you are really looking for higher density, go to copper or tungsten.

- Q:hello friends, I have some old 7.62x54r on stripper clips its nasty gunk on it can i use steel wool to glean it and still have it fire safely?

- * Yes, but I use both fine steel wool and Liquid Brasso Metal Polish on mine.* You can buy it at any Hardware and I believe Walmart carries it.* Great stuff.*

- Q:What are the different methods of transporting steel coils?

- Depending on factors such as weight, size, and distance, there are various methods available for transporting steel coils. These include: 1. Flatbed trucks: Steel coils can be transported on flatbed trucks, which have a spacious open platform for easy loading and unloading. This option is commonly used for shipments of short to medium distances and provides convenient access to the coils. 2. Rail transport: Steel coils can also be transported by rail using specialized coil cars with curved interiors to securely hold the coils. Rail transport is often preferred for long-distance shipments due to its cost-effectiveness and capacity to handle large quantities. 3. Shipping containers: Steel coils can be loaded into shipping containers for transportation via sea or inland waterways. To prevent movement during transit, the coils are usually secured inside the container using bracing or blocking materials. This method is commonly employed for international shipments and facilitates easy handling and transfer between different modes of transportation. 4. Barges: In some cases, steel coils can be transported on barges along rivers, canals, or other inland waterways. Barges are particularly suitable for large and heavy shipments, offering a cost-effective and efficient means of transportation. 5. Roll-on/roll-off (RoRo) vessels: RoRo vessels are specialized ships designed to transport vehicles and large cargo that can be rolled on and off the ship. Steel coils can be loaded onto trailers or flatbeds and driven onto the vessel, providing a convenient transportation option. 6. Air freight: Although less common due to higher costs, steel coils can also be transported by air. This method is typically used for urgent and time-sensitive shipments or when the distance is too great for other modes of transportation. Air freight offers the advantage of speed and can be a viable option in certain situations. In conclusion, the choice of transportation method for steel coils depends on factors such as cost, distance, time frame, and logistical requirements. Freight forwarders and logistics providers can assist in determining the most suitable method for a specific shipment.

- Q:What are the typical tolerances for steel coils?

- The typical tolerances for steel coils can vary depending on the specific requirements and standards of the industry. However, common tolerances for steel coils typically range between +/- 0.005 to 0.020 inches in terms of thickness, width, and length. These tolerances ensure that the steel coils meet the desired specifications and can be used effectively in various applications.

- Q:What are the common methods of transporting steel coils?

- The common methods of transporting steel coils include flatbed trucks, rail cars, and ocean vessels.

- Q:What are the environmental benefits of using steel coils?

- There are several environmental benefits of using steel coils. Firstly, steel is a highly recyclable material, meaning that it can be reused multiple times without losing its properties. This reduces the demand for raw materials and minimizes waste. Additionally, steel coils have a long lifespan, making them durable and resistant to wear and tear. This reduces the need for frequent replacements, saving resources and reducing waste. Furthermore, steel is a highly energy-efficient material, both in its production and during its use. It requires less energy to manufacture steel coils compared to other materials, and its high strength-to-weight ratio allows for lighter structures, reducing energy consumption in transportation. Overall, the use of steel coils contributes to a more sustainable and eco-friendly approach in various industries.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Prepainted Galvanized/Aluzing Steel coils for Roofings

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords