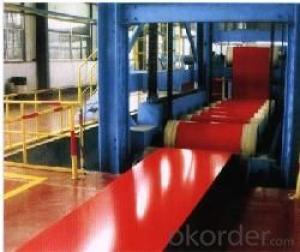

Prepainted galvalume steel coils RAL Color No.

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

colour coated steel

painting colour steel , zinc coated steel , lead coated steel

Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | DX51D,SGCC,SPCC,CGCC | Thickness: | 0.17-1.5mm |

Place of Origin: | Taian China (Mainland) | Brand Name: | HengJi | Model Number: | HJ |

Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | RAL color cremated, oiled, skin passed |

Application: |

building metal roofing components,house appliance | Width: | 914-1250mm | Length: | customized |

price: | favorable price |

|

Packaging & Delivery

Packaging Detail: | standard export packing or customized |

Delivery Detail: | 15 days after prepayment |

Specifications:

galvanized steel coil:

1.Thickness:0.17mm-1.5mm

2.Zinc coated:40g-275g/2

3.Standard:dx51d+z,sgcc

We manufacture Galvanized Steel Coils,Pre-painted Galvanized Steel Coils , etc

Prepainted steel coil features:

1. Zinc coating :40-120g(as reauired)

2. thickness:0.17-1.2mm

3. width:914-1250mm(900mm,1215mm,1250mm,1000mm the most common)

4. coil id:508m610mm

5. coil weight: 3-12(as required)

6. surface treatment:RAL color

Galvanized steel coil features:

1. Zinc coating :40-275g( as required)

2. thickness:0.17-1.2mm

3. width:914-1250mm(900mm,1215mm,1250mm,1000mm the most common)

4. coil id:508m610mm

5. coil weight: 3-12(as required)

6. surface treatment: cremated, oiled, skin passed

7. Spangle: regular,small, zero

8.Application: With excellent cold bending molded manufacturablity, good decoration effect, strong anti-corrosion ability, galvanized steel coils and sheets are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils and widely applied in construction, home appliances, decoration, ect.

Product name | steel coil,galvanized steel,galvanized steel coil |

Material | DX51D, SGCC, SPCC, CGCC, DX51D |

Normal thickness | 0.17-1.2mm |

Normal width | 900mm,914mm, 1000mm, 1200mm, 1220mm, 1250mm |

Coil weight | 3-12ns |

Certificate | BV & SGS |

Original | Shandong,China |

Payment terms | L/C or T/T |

Delivery time | within 15 ~ 25 days after 30% prepayment |

- Q:How are steel strips slit into narrower widths?

- Steel strips are slit into narrower widths using a machine called a slitter. The slitter cuts the steel strip longitudinally, creating multiple narrower strips with precise dimensions.

- Q:What are the factors that affect the fatigue resistance of steel strips?

- There are several factors that can affect the fatigue resistance of steel strips. 1. Material composition: The chemical composition of the steel, including the presence of impurities and the percentage of alloying elements, can significantly impact its fatigue resistance. Higher levels of carbon, for example, can increase the hardness and strength of the steel but may also decrease its fatigue resistance. 2. Surface condition: The surface finish and quality of the steel strip can affect its fatigue resistance. Surface imperfections, such as scratches, nicks, or corrosion, can act as stress concentrators and initiate fatigue cracks. Proper surface treatments, such as grinding or shot blasting, can improve the fatigue resistance by reducing stress concentrations. 3. Heat treatment: The heat treatment process used during the manufacturing of steel strips can greatly influence their fatigue resistance. Proper heat treatment, such as quenching and tempering, can improve the material's strength and toughness, thereby enhancing its fatigue resistance. 4. Manufacturing process: The manufacturing process itself can affect the fatigue resistance of steel strips. Variables like rolling, annealing, or cold working can introduce residual stresses or microstructural changes that can impact the material's fatigue behavior. Proper control and optimization of these processes can improve fatigue resistance. 5. Loading conditions: The type and magnitude of the applied load can also influence the fatigue resistance of steel strips. Factors like cyclic stress amplitude, stress ratio (ratio of minimum to maximum stress), and frequency of loading can all affect the fatigue life of the material. Higher stress amplitudes and stress ratios, as well as increased loading frequency, can result in reduced fatigue resistance. 6. Environmental conditions: Environmental factors, such as temperature, humidity, and the presence of corrosive agents, can affect the fatigue resistance of steel strips. Elevated temperatures can accelerate fatigue crack growth, while corrosive environments can promote crack initiation and propagation, leading to reduced fatigue life. 7. Design considerations: The design of steel strips, including their geometry, dimensions, and the presence of stress concentrators, can impact their fatigue resistance. Proper design practices, such as filleting sharp corners or adding radius to stress concentration areas, can help improve fatigue performance. In summary, the fatigue resistance of steel strips is influenced by various factors, including material composition, surface condition, heat treatment, manufacturing process, loading conditions, environmental factors, and design considerations. Understanding and optimizing these factors can lead to improved fatigue performance and longer service life of steel strips.

- Q:How are steel strips annealed for improved ductility?

- Steel strips are annealed for improved ductility through a process called annealing. Annealing involves heating the steel strips to a specific temperature and then slowly cooling them down. This process helps to eliminate any internal stresses and improve the ductility of the steel. The first step in annealing steel strips is heating them to a temperature above their recrystallization temperature. This temperature varies depending on the composition of the steel, but it is typically around 1000 to 1100 degrees Celsius. By heating the steel strips above this temperature, the existing grain structure is broken down, allowing new grains to form during the cooling process. After reaching the desired temperature, the steel strips are slowly cooled down. This slow cooling process, also known as controlled cooling or furnace cooling, is essential for achieving the desired ductility. It allows the newly formed grains to grow and align in a way that reduces internal stresses and promotes better ductility. The cooling rate during annealing is crucial as rapid cooling can lead to the formation of undesirable crystal structures and potentially reduce the ductility of the steel. Therefore, the cooling process is typically done in a controlled environment, such as a furnace, to ensure a gradual and uniform cooling rate. Overall, annealing steel strips for improved ductility involves heating them to a specific temperature above their recrystallization temperature and then slowly cooling them down. This process helps to eliminate internal stresses and promote the growth of new grains, resulting in improved ductility and better mechanical properties for the steel strips.

- Q:What are the specifications for steel strips used in the manufacturing of springs?

- The specifications for steel strips used in the manufacturing of springs may vary depending on the specific requirements of the desired spring. Generally, these steel strips need to have high tensile strength, good elasticity, and excellent fatigue resistance to withstand repeated stress and deformation. They are typically made from high carbon or alloy steels, with precise dimensional tolerances and a specific hardness range. The thickness, width, and surface finish of the steel strips are also important considerations, as they can impact the performance and durability of the springs.

- Q:How are steel strips tested for corrosion resistance?

- Steel strips are tested for corrosion resistance through a variety of methods to ensure their durability and longevity. One commonly used method is the salt spray test, also known as the ASTM B117 test. In this test, the steel strips are exposed to a highly corrosive salt spray environment for a specified period of time. This simulates the effects of corrosion that the steel strips may encounter in real-world conditions. Another method used for corrosion resistance testing is the electrochemical test. This involves immersing the steel strips in a corrosive solution and applying a small electrical current. The resulting measurements of corrosion potential and current flow provide valuable information about the material's resistance to corrosion. Additionally, some laboratories perform accelerated corrosion tests using specialized equipment. These tests subject the steel strips to extreme conditions, such as high humidity or temperature fluctuations, to accelerate the corrosion process. This allows researchers to evaluate the material's performance in a shorter time frame. Furthermore, visual inspection and microscopic examination can be conducted to assess the extent of corrosion or any signs of corrosion initiation on the steel strips. This can help identify areas of weakness and guide improvements in the material's composition or production processes. Overall, a combination of salt spray testing, electrochemical testing, accelerated corrosion tests, and visual examination are employed to comprehensively evaluate the corrosion resistance of steel strips. By conducting these tests, manufacturers can ensure that their steel strips meet the required standards and are capable of withstanding corrosive environments, thus ensuring their long-term reliability and performance.

- Q:What are the common applications of galvanized steel strips?

- Some common applications of galvanized steel strips include roofing, construction, automotive manufacturing, electrical conduits, and fencing. The galvanized coating helps to protect the steel from corrosion and increases its durability, making it suitable for various outdoor and industrial uses.

- Q:Can steel strips be used in the manufacturing of appliances?

- Yes, steel strips can be used in the manufacturing of appliances. Steel strips are commonly used in the appliance industry due to their strength, durability, and ability to be formed into various shapes and sizes. They are used in the production of components such as panels, frames, and brackets, providing stability and structural support to appliances.

- Q:What are the safety precautions for handling steel strips?

- Some safety precautions for handling steel strips include wearing appropriate personal protective equipment (PPE) such as gloves and safety goggles to protect against cuts and flying debris. It is important to use proper lifting techniques and equipment to prevent strain or injury, and to ensure that the strips are stored and stacked in a stable manner to prevent them from falling or causing accidents. Regular inspection of the strips for any defects or sharp edges is also necessary to minimize the risk of injuries.

- Q:What are the different sizes of steel strips available?

- A wide variety of sizes are offered for steel strips to meet the needs of different industries and applications. Steel strips come in different widths, thicknesses, and lengths. When it comes to width, steel strips can be as narrow as a few millimeters or as wide as several hundred millimeters, depending on their intended use. Narrow steel strips are commonly used in applications like electrical enclosures, automotive components, and small-scale machinery. On the other hand, wider steel strips are often used in construction, the manufacturing of large equipment, and for structural purposes. The thickness of steel strips can also vary greatly. Thin steel strips, typically measuring a few millimeters or less, are used in applications that require flexibility and weight reduction, such as the production of electronic devices, packaging materials, and thin-walled tubing. Thicker steel strips, ranging from several millimeters to a few centimeters, are used in heavy-duty applications like construction, shipbuilding, and industrial machinery. Steel strips are commonly supplied in coil form, which makes handling and transportation easier. The length of steel strips in a coil can vary depending on the manufacturer and customer requirements. Standard coil lengths typically range from a few meters to several hundred meters, ensuring that steel strips can be easily cut and shaped to fit specific project needs. In conclusion, the availability of steel strip sizes is extensive, with variations in width, thickness, and length, allowing for a wide range of applications across various industries.

- Q:Are steel strips cost-effective compared to other materials?

- Yes, steel strips can be considered cost-effective compared to other materials for various applications. Steel is a versatile material that offers several advantages such as high strength, durability, and resistance to corrosion. These qualities make steel strips suitable for a wide range of industries, including construction, automotive, manufacturing, and infrastructure. In terms of cost, steel strips can be a cost-effective choice due to their long lifespan and low maintenance requirements. Steel is highly durable and can withstand harsh environments, reducing the need for frequent repairs or replacement. This longevity can result in significant cost savings over time. Additionally, steel is readily available and has a consistent supply, which helps maintain its affordability. The production processes for steel have become more efficient over the years, further contributing to its cost-effectiveness. Furthermore, steel strips can be easily fabricated and customized to meet specific project requirements, reducing wastage and optimizing resource allocation. This flexibility adds to the overall cost-effectiveness of using steel strips. However, it is essential to consider specific project requirements, such as the desired application, budget, and environmental factors, before determining the cost-effectiveness of steel strips compared to other materials. Each material has its own unique characteristics and associated costs, so a thorough analysis should be conducted to ensure the most suitable and cost-effective choice is made.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Prepainted galvalume steel coils RAL Color No.

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords