Prepainted Aluminum Zinc Rolled Coil For Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

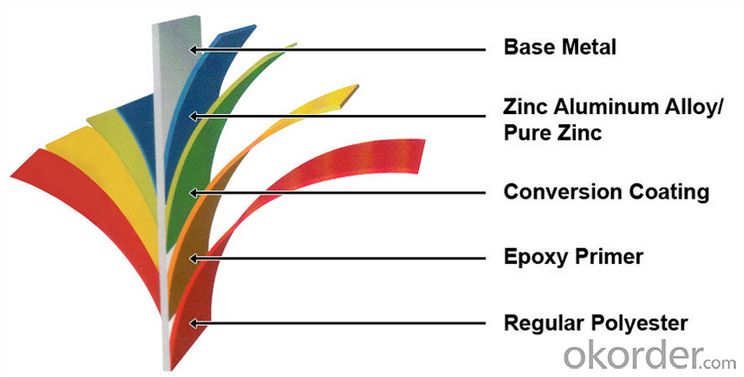

Structure of Prepainted Aluminum Zinc Rolled Coil For Construction

Description of Prepainted Aluminum Zinc Rolled Coil For Construction

Aluminum zinc coils is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Prepainted Aluminum Zinc Rolled Coil For Construction

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Prepainted Aluminum Zinc Rolled Coil For Construction

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Prepainted Aluminum Zinc Rolled Coil For Construction Images

Specifications of Prepainted Aluminum Zinc Rolled Coil for Construction

Commodity | Hot Dipped Galvalume Steel Coil/Sheet | |||

Standard | JIS G3321 / ASTM A792M / EN10215 | |||

Grade | SGLCC/SGLCD/SGLC490/SGLC570/CS TypeA,B,C/DS/255/DX51D+AZ/DX52D+AZ/S250GD+AZ/S350GD+AZ/S550GD+AZ | |||

Chemical Composition | 55%Al,43.5%Zn,1.5%Si | |||

Thicknees | 0.16-2.0 mm | Width | 600-1250mm | |

Aluzinc Coating | AZ30-AZ200 g/m 2 | Coil Weight(Min or Max) | 3-8 tons | |

Coil Inner Diameter | 508mm | 610mm | Coil Outer Diameter(Max) | |

Surface Treatment: | <1>Oiled | <2>Unoiled | <3>Slightly Oil | <4>Chromated Passivated |

<5>Skin Pass | <6>Anti Finger Print | |||

Surface Structure | Mini/Small Spangle | |||

Futher Process | Cut coil into Sheet | Corrugated Roofing Sheet | ||

FAQ of Prepainted Aluminum Zinc Rolled Coil for Construction

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:How are steel coils recycled?

- Steel coils can be recycled through a process that involves melting them down in a furnace, removing impurities, and then shaping the molten steel into new coils or other steel products. This recycling method helps conserve resources, reduce waste, and significantly cut down on energy consumption compared to producing steel from raw materials.

- Q:How are steel coils used in the production of steel screws?

- Steel coils are used in the production of steel screws by being unwound and fed into a machine that cuts and shapes them into individual screw blanks. These blanks are then threaded and undergo various processes to create the final steel screws.

- Q:The knife will be large and thick. Like the Bowie knife Rambo uses in Rambo III. It doesn't need to be flexible or to hold the edge very well. But i need it to be exceptionally strong material and to stop corrosion at least decently. Is Damascus Steel good?Thank you, in advance.

- Damascus steel is the poorest quality. The laminations separate under stress. Centuries ago the only way to get steel bars was to make it up by hammering wires together in a series of welds. The welds usually were porous and the steel would fail. The pattern of the welds is attractive to some people. An old file has good hard steel and wiill make up into a knife if it is annealed to make it easier to shape and cut. The hardness can be restored by tempering. Treating with oil is the cure to prevent rust.

- Q:How are steel coils used in the production of industrial valves?

- Steel coils are used in the production of industrial valves as they are typically cut and formed into various components, such as valve bodies and stems. The coils provide a strong and durable material for the valves, ensuring their reliability and longevity in industrial applications.

- Q:What are the different methods of embossing steel coils?

- There are several different methods of embossing steel coils, each with its unique characteristics and applications. Some of the most common methods include: 1. Hot embossing: This method involves heating the steel coil to a high temperature and then pressing it between two engraved rollers. The heat softens the steel, making it easier to imprint the desired pattern onto the surface. Hot embossing is often used to create intricate designs or textures on steel coils. 2. Cold embossing: In contrast to hot embossing, cold embossing does not involve heating the steel coil. Instead, it uses pressure and specially designed dies or stamps to create the desired pattern on the surface. Cold embossing is commonly used for simpler designs or when heat-sensitive materials are involved. 3. Roller embossing: Roller embossing is a method that utilizes a series of rollers with engraved patterns to imprint the design onto the steel coil. The steel coil is passed through the rollers, and the pressure applied causes the pattern to be transferred onto the surface. This method is often used for larger-scale production and can achieve consistent and uniform results. 4. Laser embossing: Laser embossing is a modern method that utilizes laser technology to create patterns on steel coils. The laser beam is directed onto the surface, selectively melting or vaporizing the metal to create the desired design. This method offers high precision and flexibility, making it suitable for intricate and detailed patterns. 5. Press embossing: Press embossing involves the use of a press machine equipped with custom-made dies to imprint the desired pattern onto the steel coil. The coil is placed between the dies, and the press machine applies pressure to transfer the pattern onto the surface. This method is commonly used for large-scale production and can achieve high-speed and high-volume embossing. Overall, the choice of embossing method depends on various factors such as the desired design complexity, production volume, material properties, and cost considerations. Each method has its advantages and limitations, and manufacturers must carefully select the most suitable method for their specific requirements.

- Q:How are steel coils used in the production of electrical equipment?

- Steel coils are used in the production of electrical equipment as they serve as the core material for various components, such as transformers and inductors. The magnetic properties of steel make it ideal for creating a magnetic field, allowing for efficient energy transfer and voltage regulation. By winding the electrical wires around the steel coils, the magnetic field can be generated, enabling the proper functioning of electrical devices and equipment.

- Q:I got a muzzy carp point arrow and its head is steel with 1.7% carbon, its used in the water. Will i have to dry it after every use or is it stainless. Thanks

- Stainless steel is not rust proof. it's just rust resistant. It will rust. It just takes much longer to do so... So, yes, I'd dry it well after use, and even consider wiping it with a cloth containing a very lite coating of oil.

- Q:How are steel coils used in the production of roofing panels?

- Steel coils are used in the production of roofing panels by being fed through a machine that shapes and cuts the steel into the desired panel size and shape. The coils are unrolled and flattened, then passed through a series of rollers to form the corrugated or flat panel profile. This process ensures the panels have the strength and durability required for roofing applications.

- Q:my friend needs sensitive ears....she wants to borrow mine but it says surgical steel,what does that mean?

- Surgical steel is a steel alloy that is free from any metals that are known allergens, such as nickel. It is widely used for surgical instruments and appliances. If you do lend your earrings, they should be sterilized before she wears them, and sterilized again when you get them back.

- Q:What is the best butcher's steel around $20? I'm looking for a good tool to straight out some kitchen knives. thanks

- Butcher Steel

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Prepainted Aluminum Zinc Rolled Coil For Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords