Prepainted Aluminium Coil for Industry Use with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Structure of Prepainted Aluminium Coil for Industry Use Description:

It is used as roof panel, wall panel in steel structure in warehouse, factories exhibition hall container houses, cold storage. It is also mainly used in light industry, automobile, construction, animal husbandry, fishery and commerce, etc. PE PVDF Color Coated Aluminum Coil for Curtain Wall and Ceiling and PE PVDF Color Coated Aluminum Coil for Reflector, Name plates, Advertising board, Decorated Wall.

2.Main Features of Prepainted Aluminium Coil for Industry Use:

1 light weight, ease of processing

2 high peel strength

3 super weather ability

4 Even coating and multiple colors

5 Excellent impact resistance

6 excellent flame retardant

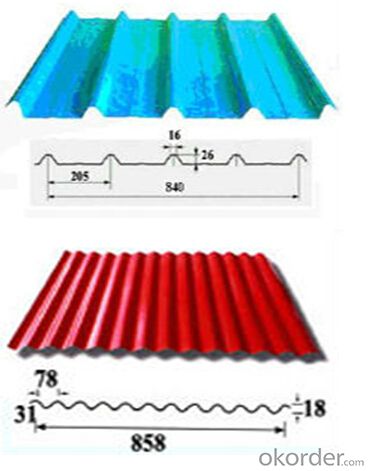

3. Prepainted Aluminium Coil for Industry Use Images:

4. Prepainted Aluminium Coil for Industry Use Specification:

Coating | Alloy | Temper | Thickness | Width | Length | Color |

PE, PVDF | 1100, 1050, 1060, 1070, 3003, 3005. | O, H12,H22, H14,H24, H16,H26, H18 | 0.05mm-2.0mm | 50mm-1500mm | Coil, about 2 ton per coil | Any color, or according to client’s sample |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q:Aluminum foil insulation material

- Aluminum foil usually compound with sound insulation cotton and sound insulation rybber. It is a thermoprinting material by calendering aluminum into a plate. Its thermoprinting effect is similar to that of silver coil thermoprinting, thus it is alos called fake silver coil. Because of its softness, malleability and silver gloss, teh calendered plate can be processed into a alumnium foil plate by pasting something like solidium silicate on the offset paper and also can be printed.However, since the color of alumnium foil may dark as a result of oxidation or fade due to friction or touching, thus it is not suitable for thermoprinting long-preserved book cover.

- Q:My team and I were running a experiment on a self made electrolytic capacitor, made by aluminium foil, baking soda in water and some tissue papersAnd well we don't really have much knowledge on capacitor, so am here to ask for some awesome explanation DIn our experiment, we are making the concentration of baking powder in water as the variable.Does the concentration of baking soda affect the capacitance? When we did our experiment the reading on a multimeter seems strange with 2.51microFarad in 20g/1000ml and 40g/1000ml with a reading of 5.31 microFarad.Need some help here to clarify things gt;_lt;So is electrolytic capacitor a dielectric?If so does that means that increase in concentration of Baking soda will increase the capacitance because the K value increase O.OAbit confused with my own experiment, been trying hard to seek some explanation from the internet but end up with nothing gt;lt; help pls thanksssss in advance D

- The dielectric material in an electrolytic capacitor is aluminum oxideThe electrolyte merely serves to create a thin layer of aluminum oxide on the foilWhat governs the capacitance is the way in which you form the capacitor, by applying a steady DC voltageA higher voltage will give a lower capacitanceWait until the current has dropped to a couple of microampsThe concentration of baking soda will govern this forming timeSo you want a graph of capacitance versus voltage, and another of forming time versus concentrationMake a careful not of the temperature, of course.

- Q:Me and a few friends are helping out a friend who is moving into a new place.Her new place is empty, she has nothing no sofa, bed, tv or anything, not even any money leftWe are piling up a list of what are the essentials she will need, so we can get them for her tomorrow.So far we have a sofa, bed, kettle,toaster,cups, tableware's,table, tv, wardrobe, lamp,curtains.Anything else?

- List of things you should never leave out are kitchen ware like knifes,spoons, plates, pans, pots, Sanitary ware, Electrical plugs and other electrical devices needed , Toilet paper, table lambs, Ceiling fansIf you guys are low on money why dont you go check out some yard sales or go on-line to find cheap furniture Also try and look for furniture in junk stores of buy some second hand stuff

- Q:what is the melting temp of aluminum?

- Does Jello Clean Your System

- Q:between the elements oxygen, scandium, aluminum, or cesium? thank youuu

- OxygenSince, metals like aluminum and cesium have tendency to lose electronsSo, it will have less pull on its valence electronsScandium is also a metal and has the same tendency to lose electronsSo, it will have less pull on its valence electronsOxygen, being a non-metal has higher affinity for electrons due to its high electronegativity, and hence would like to have the strongest pull on its valence electronsThe electronegativity values for other elements is very less as compared to oxygenHope this helpsWW.

- Q:Is it ok to use aluminium foil baking trays without greaseproof paper?

- its just caused by the butterits just caused by the butter drying and crisping in the panits harmlessthey actually make tin foil holders without the paperits all the sameyou dont even have to grease the inside of it.

- Q:A well Isolated container contains a mixture of 15 grams ice and 350 grams of water at a temperature of 0 C A 300 gram piece of aluminum is heated to a temperature of 140 C and is then submerged in the water-ice mixtureNo heat enters or leaves the container from the environmentthe specific heat of water is 4180 J/kg Cit takes 3.33x10^5 Joules of heat to melt one kilogram of iceThe specific heat of Aluminum is 900 J/kg C.awhat will be the final temperature of the solution? bActually, although heat may not go into the air, it will go into the containerIf the container is a 600 gram glass cup ( specific heat of glass is 664 J/kg C), the final temperature of the water-aluminum mixture will be lower than what you found in (a)What will be the final temperature?

- everything settles out at t degreesthe energy to melt the ice (0.015)(3.33 x 10^5) + energy to heat 365 (350 + 15) grams of water to t degrees (0.365)(4180) t the energy that the aluminum gives to the system (0.300)(900)(140-t) 4995 + 1525.7 t 37800 - 270 t 1795.7 t 32805 t 18.3 degrees b) 4995 + 1525.7 t + (0.6)(664) t 37800 - 270 t 2194.1 t 32805 t 15 degrees.

- Q:I need to know what type of paper bags to use to make luminariesWe are doing this for VBSThe kids will be using a paper punch to make their designs.

- There is no wayatleast not that I can think of in a non-toxic mannerWater would break down the bagThe only thing I can think of is to make sure your candle is directly away from the paper and to line the inside of the bag with a liberal amount of aluminum foil.

- Q:wht alloy can used for air conditioner condenser colis material

- I am not very sure, but the 'cotton yarn' that you r referring, is the thread thick like yarn or thin like normal thread? and the rough thing that you are talking about, is it like thin in some places and thick? Is the fabric a bit shiny like silk? It might be BURLAPIt has a jute like texture with wide loose weave, thou not shinyBut its mostly used in home decorSorry if I havent helped enough :)

- Q:Okay, so my parents are out of town for the weekend and they won't be back until the latest Monday nightAnyone have some great pranks?Nothing to extreme that would involve me messing up the house and I'm very limited on money and I don't want it to hurt anyoneAlso no pranks like telling them I'm pregnant or something like that.I want some good pranks!It can be anything from putting a rubberband on the faucet to putting police tape all around the houseAnything would be greatPS my parents aren't old and their blood pressure and heart are perfect.

- Pull up the sheets on their bed and lay out about a two foot section of aluminum foil on each side where they sleep, and then carefully put the sheets back in placeAlso put a one foot long section of aluminum foil in the pillow case and place the pillow foil-side down (so they can't see it).

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Prepainted Aluminium Coil for Industry Use with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords