Preheating Continuous Feeding system

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

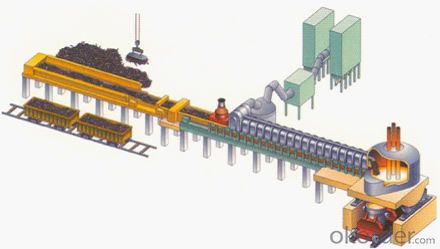

Preheating Continuous Feeding system

AE series preheating continuous feeding equipment is the most advanced, clean, energy saving and environmental protection metallurgy off gas using equipment in nowadays. This is using the off gas from the electric furnace to preheat the raw materials, and avoided the high failure rate, complicated operation, can not charging materials continuously and etc weakness from Shaft furnace preheating and preheating bucket and etc traditional ways. This system has been put into production in more than 20 factories in china and several other countries. And had gain marked affects in electricity saving, energy saving, production increasing, pollution reduction, and brings great economic benefits for customers.

AE series preheating continuous feeding equipment has characteristics of continuous feeding, continuous melting, continuous smelting and etc… which advantages are: short smelting period, low power consumption, low noises, low investment cost and etc…

Compared with the traditional EAF, the technical index of continuously preheating and feeding EAF process are:

1. Production capacity increases more than 10%.

2. Smelting cycle is shortened by 10-15 Min.

3. Save energy of 100-120kw.h/t for per ton Steel.

4. Electrode consumption decreases by 0.5-0.8%, Refractory material consumption reduces by 5%.

5. 20-30% reduction of CO2 volume which is released from per ton of Steel; Production site dustiness less than 10mg/M3.

6. Dioxin and CO emissions meets relative emission standards, smoke and dust is decreased from 17kg/t to 11kg/t.

7. Fully utilization of waste heat: On the Conveyor section can preheat the materials up to 300 degree Celsius and higher, and add burner in conveyor section, can raise the materials up to 600 degree Celsius. The rear part of the waste heat can be used to generate electricity or heating by steam which is produced by waste heat boiler, the gas from the boiler basically can go into the bag type dust collector directly. But the traditional electric furnace system off gas must go through the water cooled pipes, air forced cooler and etc equipments, it will consumable much energy to cool the temperature down and then can put the gas go into dust collector, so waste the energy from the off gas.

8. De-duster Fan power reduces 30%.

9. Noise is less than 90 decibels during the electric furnace smelting cycle.

With fully considering for customers kinds of actual using status, AE series preheating continuous feeding equipment brings direct economic benefits to customers by lowest failure rate, highest energy saving index, biggest investment return.

Main Technical Specifications

| Specification of | Dimensions of | Processing | Electric furnace |

(width*length) | (width*depth*length) | (t/h) | (t) | |

AE20S | 1260*65000 | 300*300*500 | 120 | 15-20 |

AE40S | 1400*46300 | 400*400*700 | 150 | 30-40 |

AE60S | 1840*48800 | 450*450*1000 | 200 | 50-60 |

AE70S | 2060*60000 | 500*500*1100 | 250 | 70 |

AE90S | 2140*60000 | 500*500*1100 | 300 | 80-90 |

AE150S | 2260*65000 | 500*500*1200 | 350 | 100-150 |

- Q:What's the role of anchor bricks in industrial furnaces?

- The wall of an industrial furnace or flue is mainly composed of an inner lining layer, a heat insulating layer and an outer wall layer. The lining is a refractory brick, and the outer wall is an ordinary sintered brick.

- Q:What is the difference between industrial furnaces and boilers?

- A boiler is a mechanical device for heating water into hot water or steam by the use of heat from fuel or other sources of energy. The original meaning of a pot is a water container heated by fire. The furnace is the place where the fuel is burned. The boiler includes two parts, the cooker and the furnace.

- Q:What is the difference between industrial furnace masonry and ordinary masonry?

- Industrial furnace masonry requirements are relatively high, industrial furnaces of different uses, whether material or masonry process, have strict requirements.

- Q:Heat treatment equipment (industrial furnace), which products generally contain what kind of, which industries need to use heat treatment industrial furnace equipment.

- The main equipments of heat treatment are classified into two major categories: main equipment and auxiliary equipment. The main equipment includes heat treatment furnace, heating device, surface modification, surface oxidation device, surface mechanical enhancement device, cooling equipment, cold processing equipment, process parameter detection and control instrument; auxiliary equipment includes cleaning cleaning equipment, furnace atmosphere heating medium permeability meter preparation equipment, cooling device, quenching medium heavy transport machinery, quality testing equipment, power transmission line and auxiliary equipment, fire safety equipment, dust and other production fixture.

- Q:What are the advantages of a vacuum furnace?

- The utility model can completely eliminate the oxidation and decarburization of the workpiece surface in the heating process, and can obtain clean surfaces without deterioration layers. For cutting tools that grind only one side of grinding (such as twist grinding, the surface of the groove surface is exposed to the blade directly), the cutting performance is greatly improved.

- Q:Brief introduction to repair of industrial furnace

- The industrial furnace is the main production equipment in the machinery industry. The repair of industrial furnace directly affects the quality, high yield, long life, low consumption and safe production of the furnace.

- Q:Selection of heat preservation material for industrial furnace

- Micro nano heat insulation board.The thermal conductivity of micro nano heat insulation board is very low, only a fraction of the traditional thermal insulation material, and the insulation effect is very efficient.

- Q:What are the combustion equipments used in industrial boilers?

- The boiler is an energy conversion equipment. The energy input to the boiler has the chemical energy and the electric energy in the fuel. The boiler outputs steam with certain heat energy and high temperature water.

- Q:What is industrial furnace masonry?

- Before masonry construction, the pre process and parts that may affect the quality of masonry work shall be re tested,masonry construction shall be carried out according to the datum central line and the datum elevation.

- Q:How many kinds of industrial electric furnaces are there?

- Industrial furnace according to the heating mode is divided into two categories: one is the fuel furnace, combustion heat with solid, liquid or gaseous fuel in the furnace for heating the workpiece; the second is in the furnace, the furnace converts electrical energy to heat the heat.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Preheating Continuous Feeding system

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products