prefab steel warehouse building

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

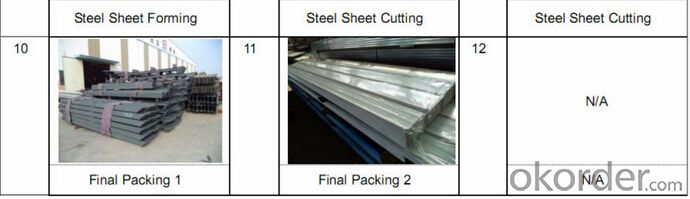

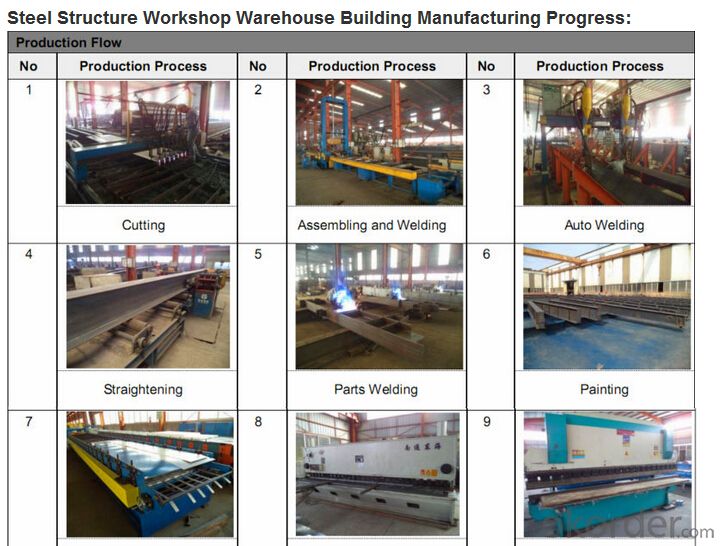

steel structure warehouse/sheds/factory Specifications

Prefabricated House.

Repeat use and long life.

Anti-rust.low cost

| Material | C Purlin, H Beam, Sandwich panel, Hot Galvanised Steel, etc. |

| Features | 1. Firm and Artistic |

| 2. Durable for 30 years at least. | |

| 3. Reusale, and Easy to intall and dismantle: usually, one worker could install 20-30 square meters per day, six workers could work out 3K*10K houses in two days. | |

4. Extensive Applications: Warehouse, Plant, Exhibition Hall, Terminal Building, Stadium, Theater, Special-shaped Buildings. | |

| 5. Hot Galvanised… | |

| 6.Flexible composition: Doors and Windows could be installed at any positions,Separate Walls could be built at any transverse axis. Stairs could be outside Steel buildings. |

- Q:How are steel structures impacted by extreme weather conditions?

- Steel structures can be significantly impacted by extreme weather conditions. For instance, strong winds, such as those experienced in hurricanes or tornadoes, can exert immense pressure on the structure, leading to bending or even collapse if the structure is not properly designed or constructed. Similarly, heavy snowfall can add substantial weight on the roof and other parts of the structure, potentially causing it to fail. Extreme heat, on the other hand, can cause steel structures to expand, which may result in warping or distortions. This expansion can also lead to the weakening of connections and joints, further compromising the overall structural integrity. Moreover, steel is susceptible to corrosion, and extreme weather conditions like heavy rain or high humidity can accelerate this process. Corrosion weakens the steel, making it more prone to failure. To mitigate the impact of extreme weather conditions on steel structures, proper design, construction, and maintenance are crucial. Designing structures to withstand the expected wind loads, ensuring adequate connections and reinforcements, and using corrosion-resistant coatings are all important measures. Regular inspection and maintenance to identify and address any signs of damage or corrosion are also essential to ensure the longevity and safety of steel structures.

- Q:What are the disadvantages of using steel structures?

- Using steel structures comes with various drawbacks. To begin with, steel is a relatively costly material in comparison to wood or concrete. Its purchase and installation expenses can significantly inflate the overall construction budget. Furthermore, steel structures are prone to corrosion, especially in environments with high levels of humidity and salt content. This can lead to the deterioration and weakening of the structure over time, necessitating regular maintenance and extra costs for protective coatings or treatments to prevent corrosion. In addition, steel structures can be vulnerable to fire. Although steel itself does not burn, it loses its strength and integrity at high temperatures. In the event of a fire, steel structures can collapse more rapidly than other materials, posing a significant safety hazard. Moreover, steel structures have poor thermal insulation properties. Steel is an excellent conductor of heat, making it challenging to maintain a comfortable indoor temperature. This can result in higher energy expenses for heating or cooling the building, as well as discomfort for occupants. Furthermore, the fabrication and installation of steel structures require skilled labor and specialized equipment. This can prolong the construction process and increase its complexity, potentially leading to delays and higher labor costs. Lastly, steel structures have limited design flexibility compared to other materials. The strength and rigidity of steel make it difficult to create curved or intricate architectural designs, constraining the aesthetic possibilities for the structure. In conclusion, while steel structures offer numerous advantages such as durability and strength, it is crucial to carefully consider these disadvantages before opting for steel in construction projects.

- Q:How are steel structures constructed on uneven terrain?

- Various techniques and methods can be employed to construct steel structures on uneven terrain in order to guarantee stability and safety. The typical procedure involves the following steps: 1. Conducting a thorough evaluation of the site: Before commencing construction, a comprehensive assessment of the terrain is carried out. This includes evaluating the slope, soil conditions, and any potential hazards that may impact the construction process. 2. Designing the foundation: The foundation is a crucial aspect of constructing steel structures on uneven terrain. Depending on the specific site conditions, different types of foundations, such as spread footings, pile foundations, or mat foundations, may be utilized. The design is based on engineering calculations that take into account the soil bearing capacity and the loads the structure will bear. 3. Grading and leveling: Typically, the site is prepared by grading and leveling any excessive slopes or irregularities in the terrain. This helps create a more even surface, facilitating the construction of the steel structure. 4. Implementing piers and columns: On uneven terrain, piers or columns can be employed to support the structure and ensure stability. These vertical elements are strategically positioned at intervals to evenly distribute the load and compensate for the uneven ground. 5. Installing the structural framing: Steel beams, columns, and trusses are then installed to establish the skeletal framework of the structure. The steel members are meticulously aligned and connected using welding or bolting techniques. Special attention is given to ensure proper alignment and levelness, particularly in areas with varying ground levels. 6. Enhancing stability and reinforcement: Additional bracing elements may be added to improve the stability and resistance of the structure. These can include diagonal braces, cross-bracing, or moment frames, depending on the design requirements and specific terrain conditions. 7. Installing floor and roof systems: Once the primary structural framework is in place, the floor and roof systems are installed. These components provide the necessary strength and support for the building and are designed to accommodate the uneven terrain if necessary. Adjustable supports or shims may be utilized to level the floors if needed. 8. Adding finishing touches: After completing the structural elements, finishing touches such as cladding, insulation, and interior partitions are incorporated. These elements generally have minimal impact on the construction process on uneven terrain as they are typically independent of the ground conditions. Throughout the construction process, it is imperative to adhere closely to the design specifications and collaborate with experienced professionals who possess expertise in constructing steel structures on uneven terrain. Additionally, regular inspections and quality control measures should be implemented to ensure that the structure is constructed to the highest standards of safety and durability.

- Q:What are the safety considerations when working with steel structures?

- When working with steel structures, several safety considerations should be taken into account. Firstly, it is important to ensure proper training and knowledge of steelwork as it involves heavy materials, complex machinery, and potentially hazardous equipment. Secondly, personal protective equipment (PPE) such as helmets, gloves, and steel-toed boots should be worn to protect against potential injuries. Additionally, proper lifting techniques and equipment should be used to prevent strains and accidents during the handling of heavy steel components. Regular inspections of the structure for any signs of damage or deterioration are crucial to maintain its integrity and prevent accidents. Lastly, following all relevant safety regulations and guidelines, and having a comprehensive emergency response plan in place, are essential to minimize risks and ensure the well-being of workers.

- Q:How are steel structures designed for storage facilities?

- Steel structures for storage facilities are designed with careful consideration of the specific storage requirements and load-bearing capacity. The design process typically involves assessing the type and weight of items to be stored, determining the optimal layout and dimensions, and ensuring structural integrity through rigorous calculations and analysis. Additionally, factors such as accessibility, safety, and future expansion are taken into account to create efficient and durable storage facilities.

- Q:How are steel roof trusses designed?

- Steel roof trusses are designed using engineering principles and calculations to ensure structural integrity and meet specific design criteria. The process involves determining the loads acting on the truss, such as the weight of the roof, snow, wind, and other factors. Then, engineers analyze and design the truss members, connections, and bracing to safely transfer these loads to the building's supports. Computer-aided design (CAD) software is often utilized to create detailed drawings and specifications for fabrication. The design also considers factors like aesthetics, cost, and construction feasibility. Overall, steel roof trusses are meticulously designed to provide a strong and durable structural system for various types of buildings.

- Q:How are steel structures used in the construction of transportation terminals?

- Steel structures are commonly used in the construction of transportation terminals due to their high strength and durability. They provide the necessary support and stability for large spans, allowing for open and flexible spaces within the terminal. Steel frames are used for the construction of terminal buildings, canopy structures, and platforms, ensuring the safety and functionality of the overall transportation facility. Additionally, steel's lightweight nature allows for faster construction and easier transportation of materials, making it an ideal choice for such projects.

- Q:How are steel structures used in data centers and server farms?

- Steel structures are extensively used in data centers and server farms due to their strength, durability, and ability to support heavy equipment. They provide the necessary framework for housing servers, networking equipment, and other critical components. Steel structures also enable efficient cable management and facilitate the installation of cooling systems, ensuring optimal performance and reliability for data centers and server farms.

- Q:How are steel structures used in the construction of automotive factories?

- Steel structures are widely used in the construction of automotive factories due to their numerous advantages. Firstly, steel is an incredibly strong and durable material, making it ideal for supporting the heavy machinery and equipment found in automotive factories. The high tensile strength of steel allows for the construction of large, open spaces without the need for excessive support columns, maximizing the usable floor area in the factory. Furthermore, steel structures are highly versatile and can be easily customized to meet the specific requirements of automotive factories. The ability to easily modify and expand the factory layout is crucial in an industry that is constantly evolving and adapting to new technologies and production methods. Steel structures also offer excellent fire resistance, providing a safe working environment for employees and protecting valuable assets. Unlike other building materials, such as wood, steel does not burn or contribute to the spreading of fires, making it an ideal choice for automotive factories where flammable materials are often present. Moreover, steel is a sustainable and environmentally friendly option for construction. It is 100% recyclable, meaning that any excess or waste steel can be melted down and reused, reducing the demand for new materials and minimizing environmental impact. In summary, steel structures play a vital role in the construction of automotive factories by providing strength, versatility, fire resistance, and sustainability. Their use allows for the creation of large, open spaces, efficient factory layouts, and a safe working environment, ultimately contributing to the overall success and productivity of the automotive industry.

- Q:What are the considerations for designing steel bridges?

- Some considerations for designing steel bridges include determining the appropriate structural system, considering the site conditions and environmental factors, selecting the appropriate materials and construction techniques, ensuring the bridge can withstand the expected loads and traffic conditions, and complying with relevant design codes and regulations. Additionally, factors such as aesthetics, maintenance requirements, and cost-effectiveness are also important considerations in the design process.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

prefab steel warehouse building

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords