precio de 1 kg acero inoxidable 304/310

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Item specifice

Standard:

ASTM

Technique:

Cold Rolled

Shape:

Square

Surface Treatment:

Polished

Steel Grade:

300 Series

Certification:

SGS

Thickness:

0.5

Width:

1219

Length:

2438

Net Weight:

12

precio de 1 kg acero inoxidable

You May Interest

| Mill and Origin? |

| Tisco(Shanxi), BAOSTEEL(Shanghai), ZPSS(ZhangJiagang) |

| Certificate of the Goods? |

| MTC would be offered by factory after preparation of the material |

| Do You Have These Goods in Stock? |

| If the dimensions are regular,we have in stock, but some special sizes need to be ordered |

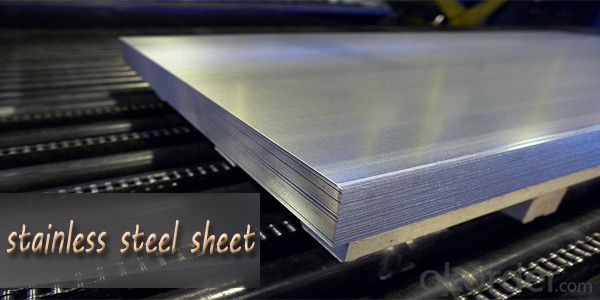

Product Description

| Item | precio de 1 kg acero inoxidable | |||

| Standard | ASTM,AISI,JIS,EN,DIN,GB | |||

| Surface | 2B | |||

| Thickness | 0.3-6mm | |||

| Width | 1000,1219mm or as customer’s requires. | |||

| Length | As customer’s requirements. | |||

| Edge | Slit/Mill Edge | |||

| Origin | TISCO,LISCO,JISCO,BAOSTEEL,BAOXIN, Eastern Special Steel etc. | |||

| MOQ | 2 Tons | |||

| Payment Term | 30%T/T; L/C at sight | |||

| Price Term | FOB/CFR/CIF | |||

| Delivery | 7-10 days after the deposit | |||

| Packaging | Seaworthy Export Standard or as customer's requests. | |||

| Application | construction field;ship building industry;petroleum and chemical industries;war and electricity industries;food processing and medicalindustry; boiler heat exchanger; machinery and hardware industry | |||

Product Show

- Q:Are stainless steel sheets suitable for high-temperature environments?

- Yes, stainless steel sheets are suitable for high-temperature environments. Stainless steel has excellent heat resistance properties, making it ideal for applications that involve exposure to elevated temperatures. It can withstand high temperatures without losing its structural integrity or corroding, making it a reliable choice for various industries such as aerospace, automotive, and manufacturing.

- Q:Can stainless steel sheets be used for elevator flooring?

- Stainless steel sheets are indeed suitable for elevator flooring. The reason behind their popularity lies in their exceptional durability, strength, and corrosion resistance. These sheets can effortlessly withstand substantial foot traffic while ensuring effortless cleaning and maintenance. Moreover, stainless steel possesses an aesthetic charm that lends elevators a sleek and contemporary appearance.

- Q:Can stainless steel sheets be polished or brushed?

- Stainless steel sheets have the ability to undergo both polishing and brushing procedures. Polishing these sheets necessitates the utilization of abrasive compounds to eliminate any surface blemishes or scratches, ultimately producing a sleek and reflective appearance. Conversely, brushing stainless steel sheets involves the usage of abrasive pads or brushes to craft a textured design or finish. This technique generates a brushed look featuring delicate parallel lines, which may be oriented either horizontally or vertically. Both polishing and brushing methods serve to heighten the visual allure of stainless steel sheets while concurrently bolstering their resistance against corrosion.

- Q:Can stainless steel sheets be used in high-pressure applications?

- Yes, stainless steel sheets can be used in high-pressure applications. Stainless steel is known for its strength, durability, and resistance to corrosion, making it suitable for withstanding high-pressure environments. It can be used in various industries, such as oil and gas, chemical processing, and power generation, where high-pressure conditions are present.

- Q:Can stainless steel sheets be used for food packaging?

- Yes, stainless steel sheets can be used for food packaging. Stainless steel is a durable and non-reactive material that does not impart any taste or odor to the food. Additionally, it provides excellent protection against moisture, oxygen, and contaminants, making it suitable for food packaging applications.

- Q:Are stainless steel sheets non-magnetic?

- No, stainless steel sheets are not inherently non-magnetic. While certain types of stainless steel can be non-magnetic, such as the austenitic variety (grades like 304 and 316), many other types of stainless steel can still exhibit magnetic properties. This is particularly true for ferritic and martensitic stainless steels. The magnetism in stainless steel is determined by its composition and crystal structure. So, if you are specifically looking for non-magnetic stainless steel sheets, you should opt for the austenitic grades.

- Q:Can stainless steel sheets be used in food processing?

- Yes, stainless steel sheets can be used in food processing. Stainless steel is a common material used in the food industry due to its many beneficial properties. It is highly resistant to corrosion, which is crucial in food processing environments where frequent contact with water, chemicals, and food is expected. Stainless steel sheets are also non-reactive, meaning they do not interact with food or affect its taste, making it a safe choice for food processing equipment. Additionally, stainless steel is easy to clean and maintain, making it suitable for maintaining high levels of hygiene required in food processing facilities. Its durability and strength also ensure that it can withstand the rigorous demands of food processing operations. Overall, stainless steel sheets are a preferred material in the food industry due to their suitability for food processing applications.

- Q:What is the fire rating of stainless steel sheets?

- Stainless steel sheets do not have a fire rating as they are not inherently fire-resistant. However, their low thermal conductivity makes them less prone to heat transfer and can help prevent the spread of fire in certain applications.

- Q:Stainless steel plate glued to tiles, what glue?

- For the high temperature does not exceed 200 degrees, and is transparent, can be used to connect the WB66 type of glue glue, the glue adhesive glue is professional, high temperature resistant and can be used in metal adhesive bonding, high speed, high strength, good toughness, long shelf life, suitable for viscose between ceramic and metal the.

- Q:How do you prevent staining or discoloration on stainless steel sheets in coastal environments?

- Preventing staining or discoloration on stainless steel sheets in coastal environments requires a combination of regular maintenance and protective measures. Here are some effective methods to prevent such issues: 1. Regular cleaning: Regularly clean the stainless steel sheets using mild soap or detergent and warm water. Gently wipe the surface with a soft cloth or sponge to remove any salt, dirt, or grime that can contribute to staining. 2. Avoid abrasive cleaners: Avoid using abrasive cleaners, steel wool, or harsh chemicals on stainless steel sheets as they can scratch or damage the surface, making it more susceptible to staining. 3. Rinse with fresh water: After cleaning, rinse the stainless steel sheets thoroughly with fresh water to remove any residual cleaning agents or salt deposits that may cause discoloration. 4. Apply protective coatings: Protective coatings specifically designed for stainless steel can be applied to create a barrier against saltwater and other corrosive elements. These coatings can help prevent staining and discoloration by providing a protective layer on the surface. 5. Use stainless steel cleaners: Regularly use stainless steel cleaners or polishes to maintain the appearance and protect the surface of the stainless steel sheets. These products can help remove any surface stains or discoloration and leave a protective layer behind. 6. Proper ventilation: Ensure proper ventilation in the area where the stainless steel sheets are installed. Good airflow can help reduce the buildup of moisture and salt in the environment, minimizing the chances of staining or discoloration. 7. Regular inspection: Regularly inspect the stainless steel sheets for any signs of staining or discoloration. Early detection can help address any issues promptly and prevent further damage. By following these preventive measures and incorporating regular maintenance, you can significantly reduce the risk of staining or discoloration on stainless steel sheets in coastal environments, ensuring their longevity and aesthetic appeal.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

precio de 1 kg acero inoxidable 304/310

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords