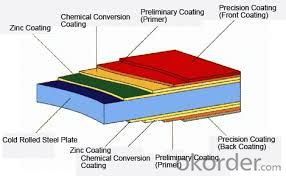

Pre-painted Steel Rolled/PPGI/Prepainted Cold Rolled Galvanized Steel Sheet Coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Prime CGCC RAL DX51D Z60 Z100 Color Coated Steel/ PPGI/Color Prepainted Galvanized Steel Coil(China)

FOB Price: US $630 - 938 / Ton Get Latest Price

Min. Order Quantity: 15 Ton/Tons

Supply Ability: 5000000 Ton/Tons per year

Port: Qingdao, Tianjin, China

Payment Terms: L/C, T/T, Western Union

Contact Supplier

Company Information

Quick Details

Standard: AISI, ASTM, BS, DIN, GB, JISGrade: SGCC SGCD SGCH DX51D/52D/53DThickness: 0.22-1.0 mm

Place of Origin: Tianjin China (Mainland)Model Number: CGCC CGCL PPGI PPGLType: Steel Coil

Technique: Cold RolledSurface Treatment: CoatedApplication: Container Plate

Special Use: Wear Resistant SteelWidth: 750-1250mmLength: Coil Or Sheet (780-6000 mm ) can be done as your requirements.

Exporting Ability: 500 20ft container/each monthZinc Coating: Z40--Z180g/m2Painting: Front side paint thickness: 15-25μ M (bottom paint + top paint)

Sample: Offer Free Sample For Quality TestContainer Info: One 20ft container can hold 26tons MaxColor: As the RAL color chart

Coil I. D: 508/610 mmCoil Weight: 3.5-8 tons/each coilOther Poducts: Cold rolled, galvanized steel coils

- Q:How many pounds can steel lift?

- I think that you failed to put up a meaningful question. I suggest that you try again and seek help.

- Q:How are steel coils used in the production of automotive structures?

- Steel coils are used in the production of automotive structures in various ways. Firstly, steel coils are used as the primary material for manufacturing car bodies and frames. These coils are typically made of high-strength steel, which is known for its durability and crashworthiness. The steel coils are processed and formed into different automotive components, such as panels, doors, roofs, and pillars. Additionally, steel coils are also used to make various structural components in an automobile. For example, they are used to create suspension systems, chassis, and other critical parts that provide stability, strength, and support to the vehicle. Steel coils are often used in the production of structural beams, reinforcement bars, and other load-bearing components that ensure the vehicle's overall strength and safety. Moreover, steel coils are used for manufacturing automotive parts that require precise shaping and forming processes. These coils are fed into stamping presses, where they undergo a series of operations like cutting, bending, and shaping to create intricate parts like brackets, brackets, brackets, and brackets. The versatility of steel allows for the production of complex automotive structures with high precision and accuracy. Additionally, steel coils are also used in the production of automotive exhaust systems. These coils are typically made of stainless steel, which offers excellent resistance to corrosion and high temperatures. They are formed and welded into exhaust pipes, mufflers, and catalytic converters, ensuring the durability and longevity of these crucial components. In summary, steel coils play a crucial role in the production of automotive structures. They are used to create car bodies, frames, suspension systems, chassis, and other structural components. Steel coils are also vital for manufacturing precise and complex automotive parts, as well as exhaust systems. Overall, steel coils contribute to the strength, safety, and longevity of automotive structures.

- Q:I would like to know if steel is basically a very dense crystal, or if it is a different atomic structure

- Steel okorder /

- Q:Specifically, for the main support beam found in a basement.

- Depends on what you mean by better. Steel is more difficult to work with and now more expensive. Glulam can do everything that you need in a home. You would be able to span further with steel, but that is not usually an issue in a home. Personally I would use glulam.

- Q:What are the different coating options for steel coils?

- There are several coating options available for steel coils, each serving different purposes and providing unique benefits. Some of the commonly used coating options for steel coils include: 1. Galvanized Coating: This coating involves immersing the steel coils in a bath of molten zinc, creating a layer of zinc on the surface. Galvanized coating provides excellent corrosion resistance and protects the steel from rusting. It is commonly used in applications where the steel coils are exposed to harsh environments or moisture. 2. Galvannealed Coating: This coating is a combination of galvanizing and annealing processes. The steel coils are first galvanized and then annealed to create a layer of zinc-iron alloy on the surface. Galvannealed coating offers enhanced paintability and weldability while providing good corrosion resistance. 3. Aluminum-Zinc Alloy Coating: Also known as Galvalume, this coating consists of an aluminum-zinc alloy applied to the steel coils. It provides excellent corrosion resistance and heat reflectivity, making it suitable for various applications, including roofing, siding, and automotive parts. 4. Organic Coatings: These coatings are typically applied as a top layer over a base coat of galvanized or galvannealed coating. Organic coatings can be in the form of paints, lacquers, or powder coatings. They provide additional protection against corrosion, UV rays, and abrasion, while also enhancing the aesthetics of the steel coils. 5. Chromate Conversion Coating: This coating is primarily used as a pre-treatment before applying organic coatings. It helps improve adhesion between the steel surface and the organic coating, ensuring better corrosion resistance. The choice of coating depends on various factors such as the intended application, environmental conditions, desired appearance, and budget. Manufacturers and end-users should carefully consider these factors to select the most suitable coating option for their specific requirements.

- Q:How are steel coils used in the production of marine vessels?

- Steel coils are extensively used in the production of marine vessels due to their strength, durability, and versatility. These coils are typically made of high-quality steel, which is known for its ability to withstand harsh marine environments and resist corrosion. One of the primary applications of steel coils in the production of marine vessels is for the construction of the hull. The steel coils are formed into plates, which are then welded together to create the hull structure. The strength of these coils ensures that the hull can withstand the extreme forces and pressures experienced during a vessel's operation, including rough seas and heavy cargo loads. Additionally, steel coils are used in the production of various components and fittings within a marine vessel. These coils can be shaped, cut, and formed into different parts, such as bulkheads, decks, and superstructures. The versatility of steel allows manufacturers to create complex shapes and structures that are essential for the efficient and safe operation of a marine vessel. Moreover, steel coils are also used for the fabrication of pipes and tubing systems within marine vessels. These pipes are crucial for various functions, such as transporting fluids, fuel, and ventilation throughout the vessel. The strength and corrosion resistance of steel coils ensure that these pipes can withstand the high pressures and corrosive nature of marine environments. Furthermore, steel coils are utilized in the production of marine vessel equipment, such as winches, cranes, and anchor systems. These components require a high-strength material that can withstand heavy loads and constant use. Steel coils provide the required strength and durability to ensure the reliable performance of these critical equipment. In conclusion, steel coils play a vital role in the production of marine vessels. Their strength, durability, and versatility make them an ideal material for constructing the hull, manufacturing various components, fabricating piping systems, and creating equipment. The use of steel coils ensures the safety, efficiency, and longevity of marine vessels, enabling them to navigate the challenging conditions of the open seas.

- Q:Can steel coils be coated with anti-graffiti materials?

- Yes, steel coils can be coated with anti-graffiti materials. These materials create a protective layer that can prevent graffiti from adhering to the surface, making it easier to remove any unwanted markings.

- Q:Is it possible that stainless steel watches get rust. Any experience? Thanks.

- Stainless can oxidize over time but it doesn't look much like regular rust. Depending on the exact composition of the stainless alloy in question and what other materials are in contact with it, that's more or less of an issue. In constant contact with skin oils and gentle polishing from contact with skin and clothing, watches rarely rust regardless of what they're made of, I think you have nothing to worry about. Note: for future reference, bleach is absolute hell on stainless. It's bad enough on steel, worse on stainless. Especially because you have this idea that stainless is more or less impervious, when in reality it just isn't.

- Q:full discription about hydrolics used in steel melting shop with hyd valve is use in thair circit too ?

- The correct spelling is hydraulics. I haven't heard the term steel melting shop you probably means a foundry or a steel mill The most obvious example i can think of is hydraulic-operated fork lifts. Hydraulic cylinders are used to lift the forks and to tilt them upwards or downwards. The valves are coneccted to levers next to the steering wheel. Hydraulic pressure is supplied by a hydraulic pump driven by a propane or diesel engine. In some forklift designs the wheels are also not connected directly to the engine, but driven by hydraulic motors. There are also a large variety of machines used in steel mills and metalworking companies to cut and shape metal parts. for example, press brakes, plate cutting shears, stamping presses, hole punch machines, drawing presses, etc. These types all operate in much the same basic way. They use a very large cylinder or group of cylinders to apply many tons of force to different kinds of metal working tools.

- Q:How are steel coils used in the production of roofing systems?

- Steel coils are used in the production of roofing systems as they are formed into sheets or panels that are then shaped, cut, and fastened to create durable and weather-resistant roofs. The coils provide the raw material for manufacturing various components of the roofing system, such as metal tiles, standing seam panels, or corrugated sheets, which offer excellent strength, longevity, and protection against harsh elements.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Pre-painted Steel Rolled/PPGI/Prepainted Cold Rolled Galvanized Steel Sheet Coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords