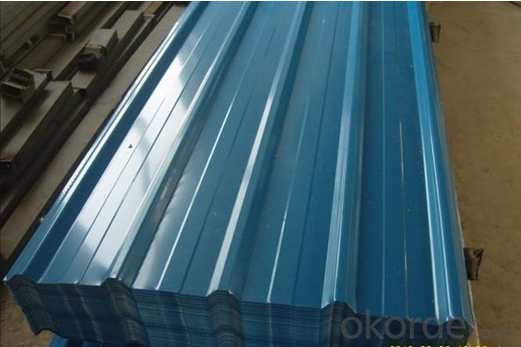

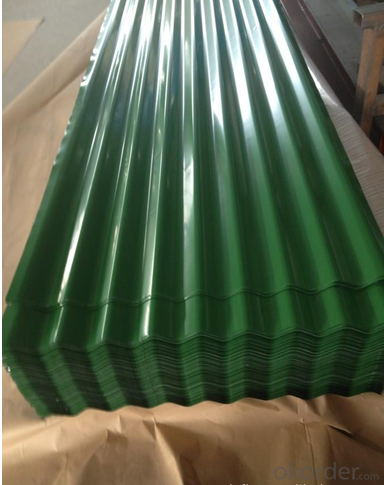

Pre-Painted Steel Coil for Building/Color Coated Galvanized Steel Coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification:

1) Standard: JIS G3302-1998/EN10142/ASTM A653/ASTM A792/ AISI/BS/ DIN/GB

2) Grade:DX51D+Z

3) Thickness: 0.12mm-0.6mm, all available

4) Width: 600mm-1250mm, all available

5) Length: according to the customer's request

6) Coil ID: 508/610mm

7) Hardness:Soft,full hard

8) Zinc Coating: 50-150g

9) Paint coating: Top 15-20mirco ,back 7mirco

10) Color series: Sea blue,white grey and all RAL color

PPGI,(PPGL,pre-painted galvanized steel coils, pre-painted galvalume steel coils,color coated steel coils.color coated galvanized steel coils)

1, Introduction: PPGI is made of galvanized steel coils or galvalume steel coils with polymer coatings as surface. It's a new enclosure material and building board

2, Product feature: Apperance of a variety of color Antirust and antiseptic,durability,etc.

3, Production Process: Pretreatment(Degreasing) DryingChromatingPaint Basic OilCoolingDryingColor CoatingCoolingFilm- coveringRolling Up

4, Application: it is ideal for a wide range of applications,, such as pre-engineered buildings, architectural panels, roofing, siding, cladding, and many other building components.and also used back plate of appliance; wide range of construction, furniture industry, transportation industry, etc.

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

- Q:What is current price of steel in US market?

- here okorder /

- Q:How are steel coils used in the production of signage?

- Steel coils are used in the production of signage as they provide a durable and versatile material for creating sturdy sign structures. The steel coils are typically cut into desired shapes and sizes, then bent, welded, or formed to create the framework of the signs. This allows for the creation of different types of signs, such as billboards, street signs, or large display signs. The steel coils' strength and resistance to weather make them ideal for outdoor signage that needs to withstand various environmental conditions.

- Q:How are steel coils used in the production of automotive wheels?

- Steel coils are used in the production of automotive wheels as the primary material for manufacturing the wheel rims. These coils are processed and formed into the desired shape, ensuring strength and durability for the wheels.

- Q:What are the common surface treatments for galvanized steel coils?

- The common surface treatments for galvanized steel coils include passivation, chromate coating, and oiling. Passivation is a process where a thin layer of protective material, such as zinc phosphate or chromate, is applied onto the galvanized steel surface. This layer helps to enhance the corrosion resistance of the steel by providing a barrier against moisture and atmospheric elements. Passivation also improves the adhesion of subsequent coatings or paints that may be applied to the steel. Chromate coating, also known as chromating or chromate conversion coating, involves the application of a thin layer of chromate onto the galvanized steel surface. This coating provides an additional layer of protection against corrosion and improves the appearance of the steel. Chromate coatings can be clear or colored, depending on the desired aesthetic. Oiling is another common surface treatment for galvanized steel coils. This involves the application of a thin layer of oil onto the surface of the steel, which helps to prevent the formation of rust and corrosion during storage and transportation. Oiling also provides temporary protection against moisture and other environmental factors until the steel is further processed or used in its final application. These surface treatments are commonly used to enhance the performance, durability, and appearance of galvanized steel coils, ensuring that they can withstand harsh conditions and maintain their quality over time.

- Q:How are steel coils used in the production of solar panels?

- Steel coils are not directly used in the production of solar panels. However, steel is typically used in the manufacturing of the structural frames and mounting systems for solar panels. These frames and mounting systems provide support and stability to the solar panels, ensuring their proper installation and long-term durability.

- Q:How are steel coils inspected for surface finish using profilometry?

- Steel coils are inspected for surface finish using profilometry by measuring the surface topography using a profilometer. The profilometer scans the surface of the steel coil and records the deviations from the ideal surface. This data is then used to determine the roughness, waviness, and other surface parameters of the steel coil, providing a quantitative assessment of its surface finish quality.

- Q:Can steel coils be coated with decorative designs?

- Yes, steel coils can be coated with decorative designs. This is commonly achieved through various coating techniques like painting, powder coating, or laminating, which can add aesthetic appeal to the steel coils while enhancing their overall appearance and functionality.

- Q:How are steel coils tested for compliance with industry standards?

- Steel coils are tested for compliance with industry standards through various methods. These include visual inspection, dimensional measurements, and mechanical tests such as tensile and impact tests. Additionally, chemical composition analysis is performed to ensure that the steel meets the required specifications. These comprehensive tests ensure that the steel coils are of high quality and meet the standards set by the industry.

- Q:I work the Copper plating line at a custom plating facility in MI.I like to use jumper cables with the jumper cable clamps to help confirm electric current is getting to my parts that I am plating. The acids in the Acid copper is constantly eating the steel and copper clamps. WIll I get a good enough current through stainless steel clamps? I use stainless steel hooks, but our maintenance man thinks that is one of the reasons why I have prblems with my parts turning out. I still think it has to do with the clamps getting eatin up. My question is Is stainless steel as good or reliable enough to run an electrical current to my parts if I am using stainless steel or is it best to use another method to try and get a better connection.Please state your sources or experience with working with electricity. I need to get honest answers and not this is my opinion. We are talking about my making a living so this is important to me so I can bring food home to my table. Thanks for all the help.

- Stainless Steel Conductivity

- Q:How does the steel coil market vary regionally?

- The steel coil market varies regionally due to several factors such as the level of industrialization, economic development, and the specific demands and requirements of each region. In developed regions such as North America and Europe, the steel coil market is relatively mature and highly competitive. These regions have well-established manufacturing industries and infrastructure, which create a strong demand for steel coils for various applications such as automotive, construction, and machinery. The market in these regions is driven by factors like technological advancements, product innovation, and the need for high-quality materials. On the other hand, developing regions such as Asia-Pacific, Latin America, and Middle East & Africa experience rapid industrialization and urbanization, driving the demand for steel coils. These regions have growing construction sectors, booming automotive industries, and increasing infrastructure projects, which contribute to the rising demand for steel coils. Additionally, the availability of low-cost labor and raw materials in some of these regions makes them attractive for steel coil production. Furthermore, the regional variations in regulations and trade policies also impact the steel coil market. Tariffs, import/export restrictions, and government initiatives to promote domestic production can affect the market dynamics. For instance, protectionist measures like trade barriers or anti-dumping policies can limit the import of steel coils, leading to increased domestic production and regional market growth. Moreover, geographical factors and climate conditions can also influence regional steel coil markets. Coastal regions with high humidity levels and exposure to saltwater require specialized corrosion-resistant steel coils, while inland regions with extreme temperatures may demand coils with specific mechanical properties to withstand such conditions. Overall, the steel coil market varies regionally due to differences in industrialization, economic factors, specific demands, regulations, and geographical considerations. Understanding these variations is crucial for steel coil manufacturers, suppliers, and consumers to effectively navigate the market and capitalize on the opportunities available in each region.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Pre-Painted Steel Coil for Building/Color Coated Galvanized Steel Coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords