Pre-Painted Galvanized Steel Sheet/Coil with High Quality Green Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

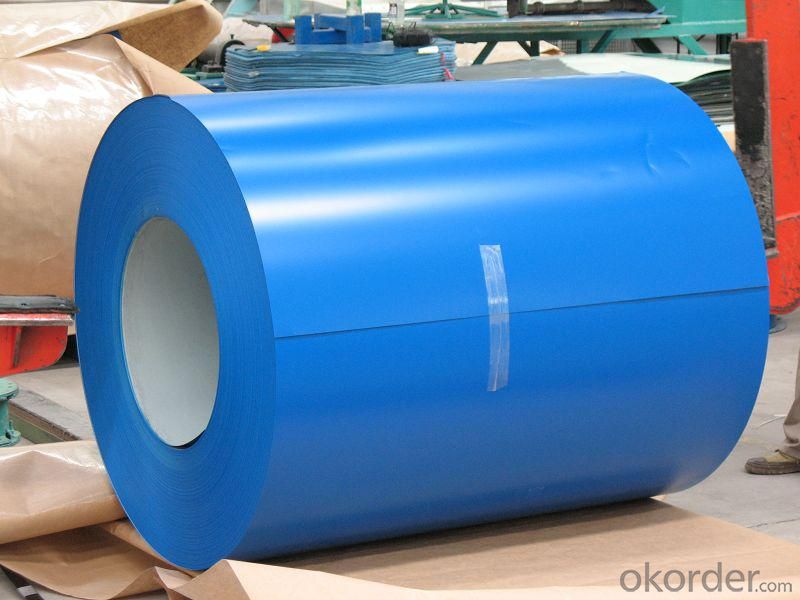

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images:

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coi

1. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q:How are steel coils used in the production of elevator components?

- Steel coils play a crucial role in elevator component manufacturing. Crafted from high-quality steel specifically designed to meet the demanding requirements of elevator production, these coils are indispensable. Elevator doors heavily rely on steel coils. These coils undergo processing into flat sheets, which are then cut into desired dimensions for door creation. The doors must possess strength and durability to endure frequent use and ensure passenger safety. Steel coils provide the necessary structural integrity and resistance to deformation, essential characteristics for elevator doors. Furthermore, steel coils find application in the manufacturing of elevator cabins. After processing, the coils are molded into various shapes to construct cabin walls and flooring. Steel's strength and rigidity make it an ideal material for this purpose, enabling it to handle heavy loads and establish a secure and stable environment for passengers. Additionally, steel coils find utility in the production of elevator shafts. Rolled into cylindrical forms and welded together, these coils serve as the structural framework for the shafts. The shafts demand strength and rigidity to support the elevator's weight and ensure smooth and safe vertical movement. Steel coils fulfill these requirements by providing the necessary strength, stability, and load-bearing capacity for this critical elevator system component. To summarize, steel coils play a vital role in the production of elevator components, including doors, cabins, and shafts. Their strength, durability, and versatility make them suitable for creating reliable and secure elevator systems that efficiently transport passengers.

- Q:what is tool steel and does it function better than carbon or spring steel?

- Tool okorder for some ideas on stuff that tool steel can be made into.

- Q:I want to save water $$, so I want to use frozen steel to cool my coke. possible or no?

- If you put steel in the freezer, allow it to cool to 32 degrees and then put it in water a transfer of heat will occur and the water will cool off. How much and how quickly, I don't know. I believe the Mythbusters did experiments on something like this. If it were economical, we woud see steel ice cubes being sold instead of ice makers.

- Q:How is the quality of steel coils determined?

- The quality of steel coils is determined by various factors such as the chemical composition, mechanical properties, surface finish, and dimensional tolerances. These factors are assessed through rigorous testing and inspections, including chemical analysis, tensile testing, hardness testing, visual inspection, and dimensional measurements. Additionally, industry standards and specifications play a crucial role in determining the quality of steel coils by setting specific requirements that the coils must meet.

- Q:Is there any other way of testing whether or not you have a 1944 Steel penny that won't damage the penny. The magnet test doesn't seem to work cause even when I try to get a 2007 penny to stick to the magnet...it won't. So is there some kind of magnet needed? Like power wise or anything like that, if not then I need to know what are other ways of testing the 1944 penny.

- Weigh it. I'm not an expert on coins, but if the 1944 was 100% steel, I would expect it to weigh something different then modern pennies. Another test would be to measure the resistance with a micro-ohm meter. This is a specialized device that can measure resistance to a millionth of an ohm. Steel should have a different resistance than the metals used on other pennies. Here are some comments from wikipedia: In 1943, at the peak of World War II, cents of zinc-coated steel were made for a short time due to war demands for copper. A few (the U.S. Mint reports forty) copper cents from 1943 were produced from the 1942 planchets remaining in the bins. Similarly, some 1944 steel cents have been reported. Following 1943, salvaged ammunition shells made their way into the minting process, and it was not uncommon to see coins featuring streaks of brass or having a considerably darker finish than other issues.

- Q:Ok, so I'm obsessed with learning how to play the guitar (I preffer acoustic)... I'm a teenage girl that wants to play rock/pop/folk music... I want to learn first how to strum... then eventually how to pick...so what type of string is better? nylon or steel?

- You should start with a steel string guitar. Guitars with nylon strings are classical guitars and are used primarily for classical music, which is why you so rarely see a pop singer playing one. Don't worry about your fingers; they will hurt a little for the first week or two whether you have steel or nylon strings and then that will go away forever. You might want to consider using light gauge steel strings (or even extra light gauge) at first to make fretting easier. Good luck.

- Q:I am using mild steel wire (very thin and bendable) for an art project, and would like to know if using a soldering torch is effective enough to get the job done. Or do I have to use a butane torch to heat the metal?BTW, is it better to use soft or hard solder?

- Soldering to steel is difficult. An electric iron may be enough depends on power. The steel must be clean. An abrasive like fine steel wool,fine sandpaper or even a rubber pencil eraser will work. Next an acid flux for the solder. Most electronic solder flux is not active enough for steel. Plumbers solder usually is. Plumbers solder is Lead free and has a slightly higher melting temp.

- Q:If you combine stainless steel with gold, does that make stainless gold?

- Nope, Stainless Steel is a tradename for a certain alloy. Regular Steel, which is formed from Ferrous Oxide (via the Bessimer Process). The stainless part is because they mixed in some other compound to give it unique qualities. Gold, on the other hand, is a pure element, and it can form alloys with other metals, but there are no guarantees what the properties will be

- Q:What are the different methods of edge wave correction for steel coils?

- There are several methods commonly used to correct edge waves in steel coils. These methods aim to eliminate or minimize the occurrence of edge waves, which are deformations that can occur along the edges of steel coils during processing or handling. One of the most common methods is called edge wave flattening. This technique involves using hydraulic or mechanical devices to apply pressure to the edges of the coil, effectively flattening out any waves or deformations. This can be done during the coil processing stage or as a separate step after the coil has been produced. Another method is known as edge trimming. In this approach, the edges of the coil are trimmed or cut to remove any waves or deformations. This can be done through mechanical shearing or using laser cutting technology. Edge trimming not only corrects the edge waves but also ensures that the coil has straight and smooth edges. Additionally, tension leveling is another popular method for edge wave correction. This technique involves subjecting the coil to tension forces, which helps to stretch and flatten out any waves or deformations. Tension leveling is typically done during the processing stage and is effective in correcting both edge waves and other surface defects. Moreover, roll leveling can be employed to correct edge waves in steel coils. This method utilizes a set of rolls to apply pressure to the coil, gradually flattening out any waves or deformations. Roll leveling is a versatile technique that can be used for various types of coil defects, including edge waves. Lastly, technology advancements have led to the development of automated edge wave correction systems. These systems utilize sensors and computer algorithms to detect and correct edge waves in real-time during the coil processing stage. This method ensures precise and consistent correction, minimizing the need for manual intervention and improving overall efficiency. Overall, the different methods of edge wave correction for steel coils include edge wave flattening, edge trimming, tension leveling, roll leveling, and automated correction systems. Each method has its own advantages and can be chosen based on the specific requirements and constraints of the coil processing operation.

- Q:How is steel sustainable as a building material?How is wood sustainable as a building material?

- In okorder /.. Properly managed then wood is a fully sustainable and green building material and from an environmental perspective is better than steel. However, it doesn’t possess the compressive strength that steel possesses and it can’t easily be worked or formed into structural components like steel can.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Pre-Painted Galvanized Steel Sheet/Coil with High Quality Green Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords