Pre-painted Galvanized Steel Coil for Better Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

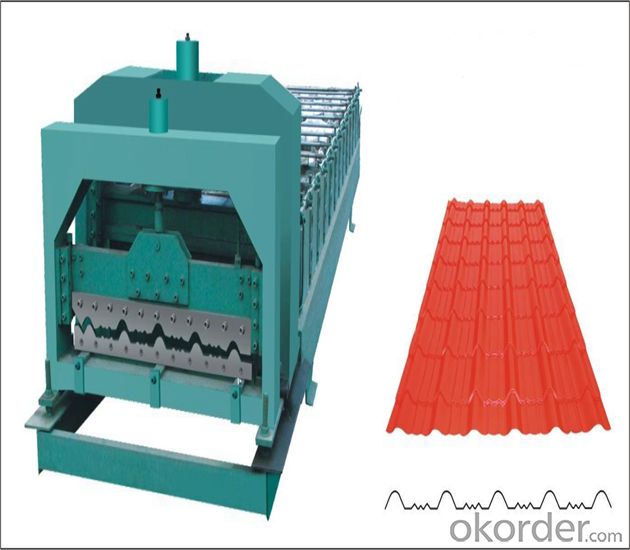

1.Structure of steel tile roll forming machine:

Steel tile roll forming machine consists of feeding, forming, after forming cutting production of color plate smooth appearance beautiful appearances, uniform lacquer veins, high strength, durable, widely used in industrial and civil buildings, such as workshop, warehouse, gymnasium, exhibition halls, theaters and other surface and wall.

2.Main Features of the steel tile roll forming machine:

The tile roll forming machine has the advantages of good corrosion resistance, colorful, beautiful appearance, convenient processing molding and the advantages of the the original strength of the steel plate and the cost is low.

First generation and second generation "automatic moulding color tile equipment" adopt "swinging cylinder driving sliding table", "swinging cylinder" belong to "moulded caigang watts equipment" is "extremely fragile" in accessories, if the forming speed is too fast, cause a large sliding table shock, buffer vibration easily, cause the tiles have crack, is the first and the second generation "stubborn" in the color tile equipment. So the fastest forming up to 6 pieces per minute.

3.Steel tile roll forming machine Images

4.Steel tile roll forming machine Specification

Steel tile roll forming machine has a lot of parameters to set, by using the text screen or touch screen setting. Parameter setting, which has two kinds of equipment parameters and user setting.

Equipment parameters: single pulse length, impulse, molding, molding time, cutter and so on.

User parameters: the number, length, pitch, the first section, small section, section number, preloading and so on.

Main moter power 5.5KW

Hydraulic station power 4KW

Hydraulic oil pump CB-E310

Sprocket P-25.4

Roller station 13

Yield strength 32MPa

Diameter of principal axis 90MM

Material of roller 45#steel hard chrome plating

Processing speed 10-15m/min

Thickness 0.3-1.2 mm

Installation dimension about(L*W*H) 7.5*1.3*1.5M

Total weight 4.2T

Equipment parts includes:roll forming system, hydraulic system, PLC frequency conversion control system, counter, cutting system,decoiler .

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1). What’s your machine installation & commissioning, training:

1or2 technicians will be dispatched to Buyer’s plant for installation & commissioning. Work period: in 5 days. The expense of round trip tickets, accommodation, safety and interpretation shall be covered by Buyer, additional pay allowance to the technicians.

2). Can you make machine according to my design?

Yes, we have experienced technical team to work out the suitable design for you and confirm with you until you agree.

3). What is the warranty for our machine?

We have one year guarantee, and provide whole life's technical support.

4).Is the machine automatic?

Yes, it can be manual and automatic.

5).what policy for broken parts?

within one year,we offer free parts. If beyond one year,you need to buy by factory cost

- Q:What are the different storage methods for steel sheets?

- Steel sheets can be stored in various ways, depending on specific requirements and available space. Here are some commonly used storage methods: 1. For small quantities or lighter sheets, a basic method is flat storage, where sheets are placed horizontally on a flat surface like the floor or metal racks. 2. Vertical storage is another option, which involves placing sheets against a wall or using specially designed vertical racks. This not only saves floor space but also allows for easy access and identification of different sheet sizes. 3. To store long and heavy sheets, cantilever racks with horizontal arms extending from a vertical column provide excellent support. These racks facilitate easy loading and unloading using forklifts or cranes. 4. Roll-out racks, equipped with rollers or ball bearings, work like drawers, allowing steel sheets to be easily rolled in and out. This method is ideal when frequent access to different sheets is required, as it offers good visibility and convenient retrieval. 5. A-frame racks, featuring angled arms resembling the letter "A," are suitable for storing large quantities of steel sheets. This method provides easy access while ensuring organization. 6. For maximum storage capacity and efficiency, automated storage and retrieval systems (AS/RS) come into play. These computer-controlled systems can be designed as vertical lift modules or robotic systems, automatically storing and retrieving steel sheets. When choosing a storage method, it's crucial to consider factors such as sheet size, weight, accessibility, and safety. Additionally, adequate measures should be taken to protect the sheets from moisture, dust, and other environmental factors that could potentially impact their quality.

- Q:What is the typical yield strength of steel sheets?

- The yield strength of steel sheets can vary depending on the grade and type of steel used, with mild steel sheets commonly used in construction and manufacturing having a typical yield strength of around 250 megapascals (MPa) or 36,000 pounds per square inch (psi). Higher strength steels, like high-strength low-alloy (HSLA) steels or advanced high-strength steels (AHSS), can exhibit yield strengths ranging from 300 to 600 MPa (43,500 to 87,000 psi) or even higher. It is important to note that these values are general estimates and specific steel grades may possess slightly different yield strengths.

- Q:How is the quality of steel sheets determined?

- The quality of steel sheets is determined by several factors and tests. One of the primary factors is the chemical composition of the steel, which includes the presence and percentage of various elements such as carbon, manganese, silicon, and alloying elements like chromium, nickel, and molybdenum. The specific composition affects the steel's strength, durability, and resistance to corrosion. Another important aspect is the mechanical properties of the steel, which are assessed through tests such as tensile strength, yield strength, elongation, hardness, and impact resistance. These tests help determine the steel's ability to withstand applied forces and deformation without failure. Surface quality is also crucial in determining the quality of steel sheets. The surface should be free from defects like cracks, scratches, pits, or any other irregularities that could affect the performance or appearance of the steel. Furthermore, the thickness and uniformity of the steel sheets are crucial factors. Thickness is measured using methods like ultrasonic gauges or micrometers to ensure compliance with the required specifications. Any deviations from the specified thickness can affect the structural integrity and performance of the steel sheets. Additionally, the steel sheets undergo various tests to assess their weldability, formability, and machinability, which determine their suitability for specific applications. These tests help evaluate the steel's behavior during fabrication processes like welding, bending, or machining. Overall, the quality of steel sheets is determined by a comprehensive evaluation of their chemical composition, mechanical properties, surface quality, thickness, and other specific performance characteristics. These assessments ensure that the steel sheets meet the required standards and are suitable for the intended applications.

- Q:How do steel sheets perform in terms of vibration damping?

- Steel sheets have good vibration damping properties due to their high density and stiffness. They are effective in reducing vibrations and minimizing noise transmission, making them suitable for various applications requiring vibration control and noise reduction.

- Q:What are the different fastening options for steel sheets?

- There are several fastening options available for steel sheets, depending on the specific application and requirements. Some common fastening options for steel sheets include: 1. Screws: Steel sheets can be fastened using screws, which are readily available and easy to use. Self-tapping screws are commonly used for fastening steel sheets, as they can create their own threads in the material. 2. Bolts and nuts: Bolts and nuts provide a strong and secure fastening option for steel sheets. They are commonly used in applications where the fastening needs to be adjustable or removable. 3. Rivets: Rivets are permanent fasteners that are commonly used to join two or more steel sheets together. They are often used in applications where a watertight or airtight seal is required. 4. Welding: Welding is a commonly used method for fastening steel sheets. It involves melting the edges of the sheets and fusing them together. Welding provides a strong and durable connection but requires specialized equipment and expertise. 5. Adhesives: Certain adhesives, such as epoxy or structural adhesives, can be used to bond steel sheets together. Adhesives can provide a clean and aesthetically pleasing connection, but their strength may vary depending on the specific adhesive used. 6. Clips and clamps: Clips and clamps are often used to secure steel sheets in place. They can be easily installed and removed, making them a popular choice for temporary or adjustable fastening needs. 7. Magnetic fasteners: Magnetic fasteners, such as magnetic strips or magnets with hooks, can be used to attach steel sheets to magnetic surfaces. This provides a convenient and easy-to-use fastening option. It is important to consider factors such as strength, durability, ease of installation, and removal when selecting a fastening option for steel sheets. The specific requirements of the application, such as load-bearing capacity and environmental conditions, should also be taken into account to ensure the chosen fastening option is suitable for the intended purpose.

- Q:Are the steel sheets resistant to staining or discoloration?

- Yes, steel sheets are highly resistant to staining or discoloration. Steel is known for its durability and non-porous surface, which makes it resistant to the absorption of liquids or chemicals that may cause staining. Additionally, steel sheets are often coated with protective finishes or treatments that further enhance their resistance to staining or discoloration. These coatings act as a barrier, preventing any potential staining agents from penetrating the surface of the steel. Therefore, steel sheets are an excellent choice for applications where resistance to staining or discoloration is important, such as in kitchen appliances, automotive parts, or outdoor structures.

- Q:What is the average weight of a steel sheet per square foot?

- The average weight of a steel sheet per square foot depends on the thickness and type of steel being used. However, a general estimate is that a steel sheet typically weighs around 40 to 50 pounds per square foot.

- Q:Can steel sheets be used in transportation applications?

- Yes, steel sheets can be used in transportation applications. Steel is a strong and durable material that can withstand the rigors of transportation, making it suitable for various applications such as manufacturing automotive bodies, constructing railway cars, shipping containers, and aircraft parts.

- Q:What are the different sizes of steel sheets available?

- The different sizes of steel sheets available can vary depending on the specific manufacturer and supplier. Common sizes include 4x8 feet, 4x10 feet, and 5x10 feet, but there are also custom sizes available to meet specific project requirements.

- Q:Can steel sheets be formed into curved shapes?

- Indeed, curved shapes can be achieved with steel sheets by means of a technique referred to as cold forming or bending. Without the need for heating, cold forming entails exerting pressure upon the steel sheet to reshape it. Roll forming, press braking, and stamping are among the different methods employed to accomplish this process. The malleability of steel enables it to be effortlessly molded into curves, thereby rendering it a versatile substance suitable for a wide range of applications in sectors like construction, automotive, and aerospace.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Pre-painted Galvanized Steel Coil for Better Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords