Pre - painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted Galvanized/Aluzinc Steel Coil Description

With GI (aluzinc) as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, It generally displays workability, durability and weather resistance.

2.Main Features of the Pre-painted Galvanized/Aluzinc Steel Coil

• Excellent corrosion resistance

• Excellent weather resistance

• High strength

• Good formability

• Good visual effect

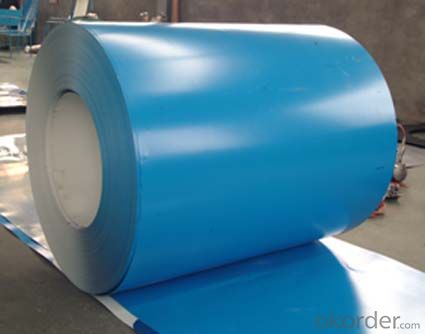

3.Pre-painted Galvanized/Aluzinc Steel Coil Images

4.Pre-painted Galvanized/Aluzinc Steel Coil Specification

Finish by coil or sheet: Both sheet and coil are available

8Zinc coating: 60-275G/M2, both sides

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, any RAL color code.

Paint thickness for back side: (5-10) microns Epoxy

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

Surface finish: with or without protect film

Thickness : 0.14-1.20 mm

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

5. FAQ of Pre-painted Galvanized/Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

3. How to guarantee the quality of the products?

every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:How are steel coils used in the production of automotive components?

- Steel coils are used in the production of automotive components as they are a primary raw material for manufacturing various parts like chassis, body panels, suspension systems, and engine components. These coils are processed and shaped using various techniques such as cutting, bending, stamping, and welding to create the required components, ensuring strength, durability, and precision in the final product.

- Q:How are steel coils used in the manufacturing of HVAC ductwork?

- Steel coils are used in the manufacturing of HVAC ductwork as they provide the necessary strength and durability required for the ductwork. These coils are typically processed through a roll-forming machine, which shapes them into the required ductwork profile. The steel coils are then cut to the desired length, welded or joined together, and finally, coated to prevent corrosion and improve the overall performance of the ductwork.

- Q:How are steel coils used in the production of automotive stampings?

- Automotive stampings heavily rely on steel coils, which are vital for their production. These coils are typically crafted from top-notch steel and are cut into specific measurements to meet automotive manufacturers' specifications. To begin the process of using steel coils for automotive stampings, the steel must first be uncoiled. This task is accomplished by a machine called a decoiler, which unwinds the coil and feeds it into the stamping machine. By utilizing the decoiler, a consistent supply of steel is ensured for the stamping process. Once the steel coil is unwound, it is inserted into the stamping machine. Equipped with a die specifically designed for shaping the steel into desired automotive components, the machine commences its work. The die is capable of creating intricate and accurate shapes, such as car body panels, doors, fenders, and structural elements. By applying force, the stamping machine presses the steel coil against the die, forming it into the desired shape. The high-quality steel utilized in the coils guarantees that the stamped components possess the necessary strength and durability required for automotive applications. Following the stamping process, the stamped components undergo a thorough inspection to assess their quality and precision. Any flaws or defects are identified and rectified prior to the components being sent for further processing, including painting, welding, or assembly. In conclusion, steel coils are of utmost importance in the production of automotive stampings. They provide a continuous supply of high-quality steel, which is skillfully shaped into precise and long-lasting automotive components. The utilization of steel coils ensures that the automotive stampings adhere to the required standards for strength, durability, and precision.

- Q:How are steel coils processed and treated?

- Steel coils are processed and treated through a series of steps. Initially, the steel is cleaned and pickled to remove any impurities. It is then passed through a series of rolling mills to reduce its thickness and increase its length. The coils are then annealed to improve their strength and ductility. Further treatments such as galvanizing or coating can be applied to enhance corrosion resistance or improve aesthetic appeal. Finally, the coils are cut and packaged according to customer specifications before being shipped for various applications in industries such as construction, automotive, and manufacturing.

- Q:So carbon is gas that brakes down to hydrogen and helium before going in...And steel can go a little farther towards sun before evaporating.. 200 degrees closer at leastso steel is full of a heavier gas bomb in my hypothesis and needs to be broken up outside stars(broken down)Is steel capable of going into sun with an element thats wrong wayLike iron has no air to boil outAnd steel goes just as far with carbon in it..Other words can u answer me with..Carbon is already IN the sun and is capable of braking down Carbon INSIDE the star/sunOnly way I see steel boiling is inside and it releases carbon gas at once..carbon bomb

- I don't know, go try it and come back and let us know how things went.

- Q:gigantic navy ships made of steel float, why??

- Believe it or not - A steel boat floats for the exact same reason all boats float. And the very best - easy to understand explanation of this (with pictures) is at the link below.

- Q:I noticed a friend's appliances are not magnetic, and mine are. Both are stainless steel. Are there two types of stainless steel or something? Thanks

- Is Stainless Steel Magnetic

- Q:I am building a steel type competative team. my team so far isempolem, skarmory , Metagross, magnezone, lucario, ferrothorn.

- Good choice in pokemon. As for moves and EVs and all that... its kinda up to how exactly you wanna play your steel team, but heres what I can think up off the top of my head: Empoleon: Mixed Attacker. Swords Dance and Aqua Jet for strong priority attacking, with two special attacks (preferrably one water and one other non steel non water attack) Skarmory: Physical wall. Skarmory is know to be an amazing physical wall. So pump HP and defense EVs into it. Impish nature is best, and try to get Roost, Whirlwind, and Brave Bird on it. Stealth Rock or Spikes for entry hazard damage. Metagross: Physical attacker. Bullet Punch is nice since Metagross is kinda slow, and Hammer Arm is decent since it hardly cares about a speed drop. Earthquake and Zen Headbutt aren't bad either. Magnezone: Bulky Special Attacker. The teams a really physical one, so having a special attacker is nice so other physical walls don't mess you up too bad. Its main attacking moves should be Thunderbolt and Flash Cannon. Sturdy and Magnet Pull are both good abilities, which one you go with is up to you. Lucario: Physical Sweeper. Max out Lucario's Attack and Speed EVs, its defenses are too low for it to take repeated hits. Close Combat and Extremespeed are Lucario staples. The other 2 moveslots depend on you. An elemental punch is good for coverage. Earthquake... is Earthquake, its good to have. There's other options too. Ferrothorn: Ferrothorn has a number of options, usually involving its great bulk. Look this one up on Smogon. Other good steel types would include: Bronzong, Scizor, Forretress. Excadrill is good, but its far better in a sandstorm team than on an all steel team (Sand Rush+Swords Dance+Focus Sash+Attack=death). Hope this helps.

- Q:Where can I find a discount online for Stainless Steel Magnetic Knife Rack

- MIU Stainless-Steel Magnetic Knife Holder List Price: $39.99 Price: $27.99 this item ships for FREE with Super Saver Shipping. Details You Save: $12.00 (30%) Product Features * Magnetic for secure hold on knives * Contemporary design * Encased in attractive 18/10 stainless steel * Measures 20 inches long, ? inch wide, 2 inches thick * 20-inch Length x .75-inch Height x 2-inch Width Product Details * Product Dimensions: 23.6 x 5.4 x 3.2 inches ; 3.8 pounds * Shipping Weight: 4 pounds (View shipping rates and policies) * Shipping: This item can only be shipped to the 48 contiguous states. We regret it cannot be shipped to APO/FPO, Hawaii, Alaska, or Puerto Rico. * Shipping Advisory: This item must be shipped separately from other items in your order. Additional shipping charges will not apply. * ASIN: B0000DZDHB * Item model number: 90009 Product Description Stainless Steel 20-inch Magnetic Knife Holder

- Q:What are the surface treatments for steel coils?

- Steel coils have multiple options for surface treatments, each with a particular purpose and unique advantages. Some popular surface treatments for steel coils are: 1. Hot-dip galvanization: This technique involves submerging the steel coil in molten zinc, resulting in a protective layer of zinc coating on the surface. Galvanization provides outstanding corrosion resistance, making the steel coil suitable for outdoor use in harsh environments. 2. Electro-galvanization: By using an electrolytic process, a thin layer of zinc is deposited onto the steel coil's surface. Electro-galvanization offers good corrosion resistance, although the coating is generally thinner compared to hot-dip galvanization. 3. Pre-painting or pre-coating: Prior to being formed into final products, steel coils can be coated with paints or other coatings. This surface treatment enhances the coil's visual appeal while providing protection against corrosion, weathering, and other environmental factors. 4. Pickling and oiling: This treatment involves immersing the steel coil in an acid solution to remove oxides and scale from the surface. After pickling, the coil is typically coated with oil to prevent rust formation during storage and transportation. 5. Phosphating: Phosphating is a chemical conversion coating process that forms a phosphate layer on the steel coil's surface. This treatment improves the adhesion of subsequent coatings, such as paints or primers, while also offering some corrosion resistance. 6. Organic coatings: Steel coils can be coated with various organic materials, including epoxy, polyester, or polyurethane, to enhance their corrosion resistance and aesthetic appearance. These coatings provide a wide range of colors, textures, and finishes, making them suitable for diverse applications. It is important to consider the intended application, environmental conditions, and desired appearance when choosing a surface treatment for steel coils. Manufacturers and end-users must carefully evaluate these factors to select the most suitable surface treatment for their specific requirements.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Pre - painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords