Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted Galvanized/Aluzinc Steel Coil Description

With GI (aluzinc) as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel.

2.Main Features of the Pre-painted Galvanized/Aluzinc Steel Coil

• Capability of decoration, molding, corrosion resistance

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

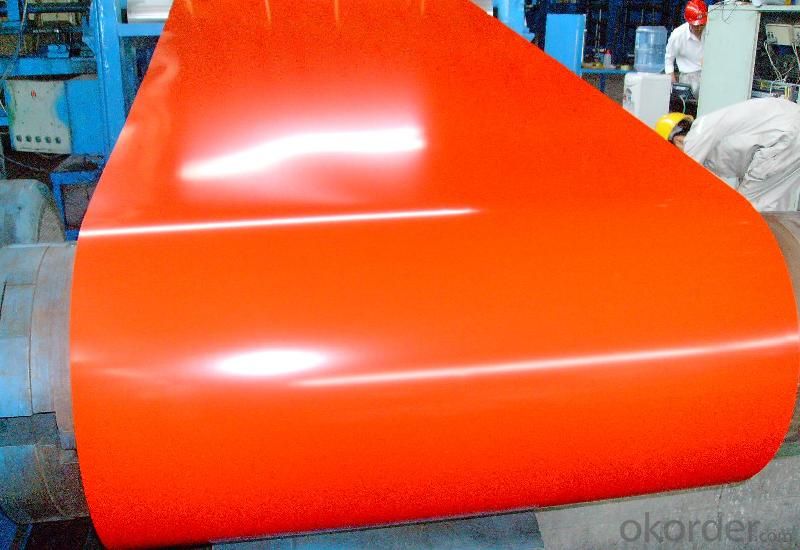

3.Pre-painted Galvanized/Aluzinc Steel Coil Images

4.Pre-painted Galvanized/Aluzinc Steel Coil Specification

Thickness : 0.14-1.20 mm

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Surface finish: with or without protect film

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

8Zinc coating: 60-275G/M2, both sides

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, any RAL color code.

Paint thickness for back side: (5-10) microns Epoxy

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

5. FAQ of Pre-painted Galvanized/Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q:What are the different types of steel coil surface appearances?

- The different types of steel coil surface appearances include hot rolled, cold rolled, galvanized, coated, and textured finishes.

- Q:How are steel coils used in the manufacturing of food packaging?

- Steel coils are commonly used in the manufacturing of food packaging as they are shaped and formed into cans, containers, and lids, providing a strong and durable material for ensuring the safety and preservation of food products.

- Q:How are steel coils used in the manufacturing of industrial compressors?

- Steel coils are used in the manufacturing of industrial compressors primarily for the construction of the compressor's casing and frame. The steel coils are shaped, cut, and welded to create the sturdy and durable structure that houses the compressor components. Additionally, the steel coils may also be used in the fabrication of other parts such as motor mounts or brackets, contributing to the overall reliability and stability of the compressor.

- Q:So carbon is gas that brakes down to hydrogen and helium before going in...And steel can go a little farther towards sun before evaporating.. 200 degrees closer at leastso steel is full of a heavier gas bomb in my hypothesis and needs to be broken up outside stars(broken down)Is steel capable of going into sun with an element thats wrong wayLike iron has no air to boil outAnd steel goes just as far with carbon in it..Other words can u answer me with..Carbon is already IN the sun and is capable of braking down Carbon INSIDE the star/sunOnly way I see steel boiling is inside and it releases carbon gas at once..carbon bomb

- Carbon NEVER breaksdown into hydrogen and helium. Steel is an alloy of iron that contains carbon. Send either into the sun and they go from being a solid to a liquid to a gas to a plasma as the temperature increases on its approach but neither breaksdown into something else. Carbon as a solid or a plasma is still carbon and the same is true for iron. There are small amounts of most elements in the sun but it is mostly hydrogen.

- Q:How are steel coils used in the production of electrical transformers?

- Steel coils are used in the production of electrical transformers as they provide the core structure for the transformer. The steel coils are wound with insulated copper wire to create the primary and secondary windings of the transformer, which allow for the transformation of electrical energy from one voltage level to another. The steel coil helps to conduct and distribute magnetic flux within the transformer, ensuring efficient energy transfer and reducing losses.

- Q:Is Stainless steel called that because.....a. Its stains lessORb. Its virtually stainless (it can't stain).Lol do you know the correct answer?????

- Stainless Steel is named that because when compared to untreated steel it is virtually stainless. It is virtually stainless, and harbors very little germs and bacteria. That is why it has been the standard in the food industry for years.

- Q:What are the common coil lengths available for steel coils?

- The steel coil lengths offered in the industry and specific requirements are subject to variation. Nonetheless, several standard coil lengths are extensively employed in different applications. These encompass coil lengths of 100 feet (30.48 meters), 200 feet (60.96 meters), 300 feet (91.44 meters), and 500 feet (152.4 meters). These lengths find extensive use in construction, manufacturing, and automotive sectors, where steel coils serve diverse purposes. It is worth mentioning that coil lengths can also be tailored to meet specific project requirements or customer preferences.

- Q:I have steel on my 9.5 ti now.. ive heard about synthetic being stronger but it snaps when it hits something sharp.. opinions people?

- If okorder

- Q:What are the challenges in coil recoiling?

- Coil recoiling, also known as coil winding, can pose several challenges depending on the specific application and requirements. Some of the common challenges in coil recoiling include: 1. Precision and accuracy: Achieving precise and accurate winding is crucial for optimal coil performance. Maintaining consistent tension throughout the winding process, ensuring proper alignment, and controlling the speed are essential to avoid variations in the coil's electrical properties. 2. Wire management: Handling the wire during the recoiling process can be challenging. The wire may be delicate, prone to tangling, or have specific handling requirements, such as being magnetically or thermally sensitive. Proper wire management techniques, such as tension control, wire guide systems, and spooling mechanisms, need to be employed to prevent wire damage and ensure uniform winding. 3. Space constraints: In many applications, coils need to fit within specific space limitations. Designing and winding coils to fit compact spaces can be challenging, especially when considering the required number of turns, wire size, insulation, and any additional components or structures that may need to be incorporated. 4. Material selection: Selecting the appropriate wire and insulation material is crucial for coil performance and longevity. Factors such as electrical conductivity, thermal properties, mechanical strength, and chemical resistance need to be considered to ensure the coil can withstand the operating conditions and environmental factors it will be exposed to. 5. Heat dissipation: Coils often generate heat during operation, especially in high-power applications. Efficient heat dissipation is essential to prevent overheating and ensure the longevity of the coil. Designing the coil with proper ventilation, utilizing cooling mechanisms, or integrating heat sinks are some of the techniques used to address this challenge. 6. Quality control: Ensuring consistent quality in coil recoiling can be challenging due to factors such as variations in wire properties, operator skill, equipment calibration, and environmental conditions. Implementing robust quality control measures, such as conducting regular inspections, performing electrical tests, and monitoring process parameters, is necessary to maintain consistent coil performance. Overall, coil recoiling requires attention to detail, precision, and adherence to specific requirements to overcome the challenges and produce high-quality coils that meet the desired performance criteria.

- Q:I am refinishing a table and on my can of polyurethane, it indicates not to sand with steel wool prior to application. Why is that?

- it can turn dark! use 400 to 600grit wetdry sandpaper watch your edges!!!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords