Pre-painted Galvanized/Aluzinc Steel Sheet Coil with High Quality and Lowest Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted GI/GL Steel Coil Description

With GI (aluzinc) as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays workability, durability and weather resistance.

2.Main Features of the Pre-painted GI/GL Steel Coil

• Excellent corrosion resistance

• Excellent weather resistance

• Capability of decoration, molding, corrosion resistance

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

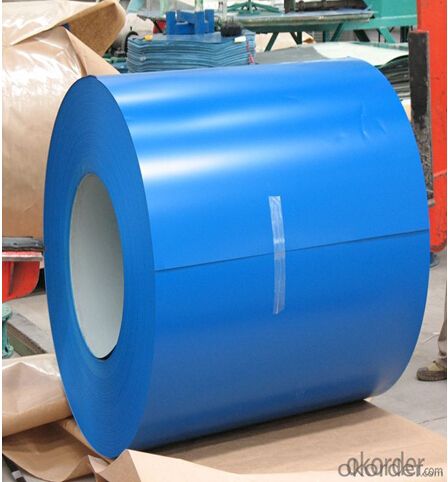

3.Pre-painted GI/GL Steel Coil Images

4.Pre-painted GI/GL Steel Coil Specification

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

Surface finish: with or without protect film

Thickness : 0.14-1.20 mm

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

8Zinc coating: 60-275G/M2, both sides

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, any RAL color code.

Paint thickness for back side: (5-10) microns Epoxy

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

5. FAQ of Pre-painted GI/GL Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:I was watching a documentary on the samurai vs the European knight. It said that the when Japan was being invaded by the (cant remember) they needed a new weapon. The enemies armor made iron swords useless. While steel swords broke when in combat. So to combat this the Japanese made a hybrid sword. They used a special mold that made the swords back iron while the part that makes contact with the enemy was steel. Also the sword was curved so it increased its armor and cutting power. This revolutionary design made the the sword stronger. The iron back made it not break while the steel edge made it cut through the enemies armor. I want to know how iron is stronger than steel, and how steel can cut better than iron.

- Yes because metal alloys are comparatively more strong than pure metal.The worst thing is that iron gets rusted whereas steel does not.And the skyscrapers are made of steel buddy , iron is not used in them.

- Q:What are the common packaging defects in steel coils?

- Some common packaging defects in steel coils include improper wrapping, inadequate strapping or banding, loose or damaged packaging materials, moisture or water damage, and insufficient protection against impacts or abrasion.

- Q:Are steel coils used in appliances manufacturing?

- Yes, steel coils are commonly used in appliances manufacturing. They are widely used for constructing the frames, cabinets, and other structural components of various appliances such as refrigerators, washing machines, dishwashers, and ovens. Steel coils provide strength, durability, and stability to these appliances, making them an essential component in their manufacturing process.

- Q:This needs to be in a percentage by mass. Could you please also reference where this info has come from. Thanks.

- Steel is produced in different grades,depending on the amount of iron, and chromium, and any other alloying metal that might be in that particular grade. Any good welders hand book would be a good source of information on steel and its properties.

- Q:Is this a strong, durable piece of steel that can take abuse? I'm thinking about using it on a small project.

- Hey Ramzi, I met this chick and was wondering if you could tell me if she would make a good wife. Here's your answer: Big Blue, there are a hundred bits of information I would need, and even then there are mysterious factors that affect the outcome. So basically, I don't have the slightest idea. My answer to your question is exactly the same. Without showing exactly how the Simpson Tie is being used, there is obviously no way to know if it is suitable. Can it be tempered? Sure, but again, I give it a 99% likelihood it will not help in your application. Explain it in detail in 5 to 10 sentences. Give us diagrams and photos. If you can't or won't do that, here's Plan B. Head over to your nearest machine shop, and ask the machinist what he thinks. He will ask the probing questions to understand the needs of the part. It is likely a Simpson Tie won't do it but he is in a good position to suggest a workable approach, and then sell it to you. By the way, if this is a load-supporting member of a motorcycle or some other fast moving vehicle, be prepared to get kicked out of the machine shop. The risk of making an error is high and the outcome extremely dangerous. I would not risk a million dollar lawsuit in order to sell you a $10 part.

- Q:why does steel have a density range when other metals do not?

- Steel is not a pure element it is an alloy. Steel is primarily iron but it has many elements blended in that change it's density including carbon,silicon, nickel, chrome, etc. Aluminum and copper , magnesium and so forth can be the pure element or they can be alloys too. If they are alloys, then their densities vary also

- Q:Are steel coils used in shipbuilding?

- Yes, steel coils are commonly used in shipbuilding. These coils are typically made of high-quality steel and are used in various parts of the ship's structure, such as the hull, decks, and bulkheads. The use of steel coils ensures the strength, durability, and structural integrity of the ship, making it capable of withstanding the harsh marine environment and heavy loads.

- Q:How do steel coils contribute to the HVAC industry?

- Steel coils are an integral component of the HVAC (Heating, Ventilation, and Air Conditioning) industry and play a crucial role in the functioning and efficiency of HVAC systems. These coils are typically made from high-quality steel, such as stainless steel or galvanized steel, which ensures durability and resistance to corrosion. One of the main ways steel coils contribute to the HVAC industry is by facilitating heat transfer. HVAC systems use coils to transfer heat between the air and a refrigerant. In air conditioning units, for example, the evaporator coil absorbs heat from the indoor air, while the condenser coil releases heat to the outside air. The steel coils in these units provide a large surface area for efficient heat exchange, enabling the cooling or heating of the air as required. Moreover, steel coils also contribute to the overall energy efficiency of HVAC systems. By maximizing heat transfer, these coils allow HVAC systems to operate at optimal performance levels while consuming less energy. This not only helps reduce energy costs for users but also makes HVAC systems more environmentally friendly by minimizing energy consumption and greenhouse gas emissions. Steel coils in HVAC systems also contribute to the quality of indoor air. As air passes over the coils, any impurities, such as dust, dirt, or mold, can accumulate on the coil's surface. Regular maintenance and cleaning of the coils are essential to prevent the buildup of contaminants that could negatively impact air quality. Properly maintained steel coils ensure clean and healthy indoor air, which is particularly important for commercial buildings, hospitals, and other spaces where air quality is crucial. In addition to their heat transfer and energy efficiency capabilities, steel coils also provide durability and longevity to HVAC systems. Steel is a strong and resilient material that can withstand high temperatures, pressure, and environmental stressors. By using steel coils, HVAC systems can operate reliably and efficiently for extended periods, reducing the need for frequent repairs or replacements. Overall, steel coils are a vital component of the HVAC industry. They enable efficient heat transfer, improve energy efficiency, enhance indoor air quality, and provide durability to HVAC systems. Without steel coils, the performance and effectiveness of HVAC systems would be significantly compromised, making them an indispensable element of the HVAC industry.

- Q:What are the factors to consider when selecting a supplier for steel coils?

- When selecting a supplier for steel coils, there are several factors that need to be taken into account. Firstly, the reputation of the supplier in terms of providing high-quality steel coils is crucial. It is important for the steel coils to meet industry standards and have consistent quality to ensure the durability and performance of the final product. Secondly, the supplier should be reliable and able to consistently meet the demand for steel coils. They should have a proven track record of delivering on time and efficiently handling large orders. The cost of the steel coils is also a significant factor to consider. While competitive prices are important, it is equally important to ensure that the quality is not compromised. It is advisable to compare prices from multiple suppliers to find the best balance between cost and quality. It is also important to look for a supplier that offers a wide range of steel coil products. This will provide various options to choose from and ensure that the exact specifications and dimensions that meet the requirements are available. A supplier with technical expertise and experience in the steel industry can be valuable. They can provide advice and assistance in selecting the right steel coils for specific needs and help with any customization or special requirements. Considering the location and delivery capabilities of the supplier is also important. Choosing a supplier who is geographically closer to the facility can help reduce transportation costs and lead times. Lastly, good customer service is always preferable. The supplier should be responsive to inquiries, provide timely updates, and be willing to address any issues or concerns that may arise. By taking these factors into consideration, an informed decision can be made to choose a supplier that best meets the requirements for steel coils.

- Q:How are steel coils used in the production of automotive engine components?

- Steel coils are used in the production of automotive engine components by being processed and shaped into various parts, such as pistons, crankshafts, and connecting rods. The coils are first cut, stamped, and formed into the desired shapes, and then undergo heat treatment and other machining processes to enhance their strength and durability. These components are crucial for the proper functioning of an automotive engine, as they provide structural support and help convert the energy generated by the combustion process into mechanical motion.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with High Quality and Lowest Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords