Pre-painted Aluzinc Steel Coil Used for Industry with Good Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

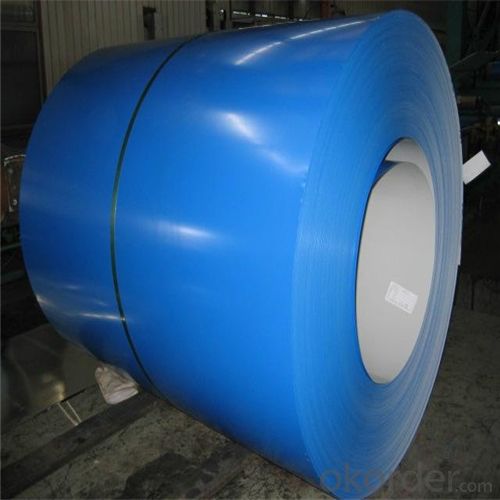

Pre-painted Aluzinc Steel Coil Used for Industry

1.Structure of Pre-painted Aluzinc Steel Coil Description

With aluzinc steel as base metal, after degrease and chemical treatment and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted aluzinc steel. Pre-painted aluzinc steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of Pre-painted Aluzinc Steel Coil

•High Purity

•Easy control and operation

•High strength

•Fast melting

•Competitive price

•Best Service

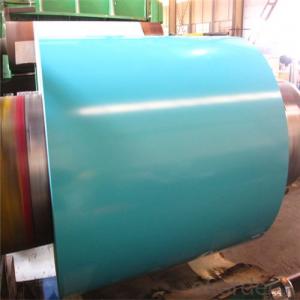

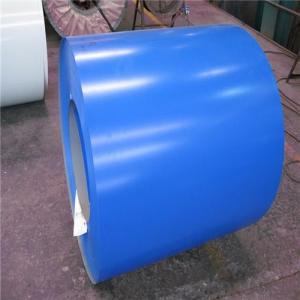

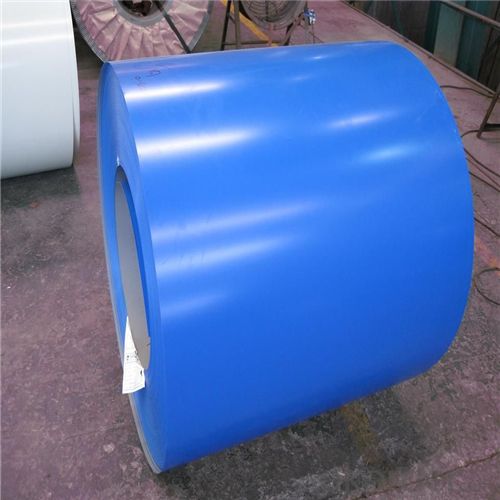

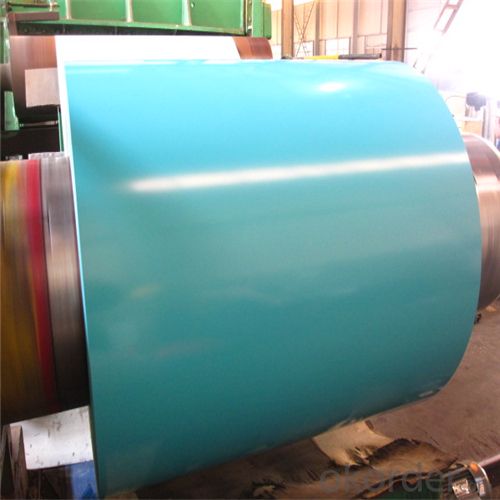

3. Pre-painted Aluzinc Steel Coil Images

4. Pre-painted Aluzinc Steel Coil Specification

Pre-painted Aluzinc Steel Coil | |

Thicknenss | 0.18mm-1.5mm |

Width | 900-1250mm |

Coating mass | 30-185g/㎡ |

Paint | PE, PVDF, PU |

Color | RAL Scale |

Coil weight | 3-7mt |

Coil inner diameter | 508 or 610mm |

5.FAQ of Pre-painted Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q:What are the different types of steel coil packaging methods?

- There are several types of steel coil packaging methods, including strapping, wrapping, and stacking. Strapping involves using metal or plastic bands to secure the coil and prevent it from unwinding. Wrapping is done by covering the coil with a protective layer, such as plastic or paper, to shield it from moisture and damage. Stacking involves placing multiple coils on top of each other, usually on pallets, to optimize storage space and facilitate transportation.

- Q:How are steel coils used in the production of metal ceilings?

- Steel coils are an essential component in the production of metal ceilings. These coils, which are typically made of high-quality steel, are used to create the base material for manufacturing metal ceiling panels. The first step in the process involves uncoiling the steel coils and feeding them into a roll forming machine. This machine gradually shapes the steel into the desired profile for the ceiling panels. The coils are passed through a series of rollers, which bend and shape the steel into the required dimensions and design. Once the steel has been shaped, it is then cut into individual panels of the desired length. These panels are then subjected to various finishing processes such as surface treatment, painting, or powder coating to enhance their appearance and durability. Steel coils are preferred in the production of metal ceilings due to their excellent strength and rigidity. They provide a sturdy foundation for the ceiling panels, ensuring their longevity and resistance to deformation. Moreover, steel coils offer superior fire resistance, making them a safe choice for use in commercial and industrial buildings. In addition to their structural benefits, steel coils also allow for a wide range of design possibilities. The malleability of steel allows manufacturers to create intricate patterns and textures on the surface of the ceiling panels, providing aesthetic appeal and enhancing the overall interior design. Overall, steel coils are an integral part of the production process for metal ceilings. They provide the necessary strength, durability, and versatility required for creating high-quality and visually appealing ceiling panels used in various commercial and residential spaces.

- Q:How are steel coils used in the production of electrical transmission towers?

- Various methods are employed in utilizing steel coils for the manufacturing of electrical transmission towers. Firstly, these coils are frequently employed in the production of the towers' structural components, including the main support columns and crossarms. To effectively bear the weight and strain of the transmission lines, these components necessitate strength and long-lasting durability, which steel coils aptly provide. Furthermore, steel coils are also instrumental in the creation of brackets and braces that reinforce the transmission towers. These particular elements contribute to the even distribution of the load and offer supplementary support to the structure. Steel coils can be molded and welded with ease, rendering them well-suited for the intricate fabrication of these components. Additionally, steel coils find extensive application in the construction of the foundation and anchor bolts that secure the transmission towers to the ground. It is vital for these bolts to possess robustness and resistance to corrosion, as they play a pivotal role in upholding the stability and integrity of the entire tower structure. To enhance their longevity and prevent rusting, steel coils are often subjected to galvanization or other protective coatings. In summary, the indispensability of steel coils in the production of electrical transmission towers arises from their exceptional strength, durability, and versatility. These coils enable the construction of robust tower structures capable of supporting the weight of transmission lines and withstanding diverse environmental conditions.

- Q:I wasn't expecting much because i knew it was cheap (Trying to avoid high prices) But anyway i cut a few bottles and cans and i noticed the very edge of the blade was starting to bend. I ignored it and tried it on a 3 inch limb, and the whole blade bent sideways where the limb hit it.I heard cold steel was supposed to be top quality and I wanted to know how durable their swords are and if they're worth it. Thanks!

- O.Adequate. First and fundamental it takes coaching and observe to use a katana. There may be a little bit component known as 'system'. You need to to search out an trainer. Except you're a fairly significant man, an O Katana is conveniently too large for you. Weapons of this way were not used for dueling, they have been further anti-cavalry weapons. As a substitute cumbersome for one in the direction of one combat. The cold steel katanas are not very regularly correct varieties of a japanese sword - missing finesse and poorly balanced. They are going to take a beating though and it seems like that's what you probably giving it. Severely, you possibly more often than not a hazard to your self and possible others round you - to search out an teacher.

- Q:What are the different methods of welding steel coils?

- There are several methods of welding steel coils, including MIG (Metal Inert Gas) welding, TIG (Tungsten Inert Gas) welding, and resistance welding. MIG welding uses a consumable electrode wire and an inert gas as a shielding medium to create an arc and join the coils. TIG welding, on the other hand, uses a non-consumable tungsten electrode and a separate filler material to create the weld. Resistance welding involves applying pressure and passing an electric current through the coils to create a weld. Each method has its advantages and is chosen based on factors such as the type and thickness of the steel, desired quality, and production requirements.

- Q:Is a steel plate the same as a steel coil?

- Generally speaking, they can be used interchangeably, and the purchase price of the plate is slightly cheaper.

- Q:What are the different coil packaging options available for steel coils?

- There are several different coil packaging options available for steel coils, depending on the specific requirements and preferences of the customers. Some of the commonly used packaging options include: 1. Steel Strapping: This is a traditional method of packaging steel coils, where a high-tensile steel strap is used to secure the coil. It provides excellent stability and protection during transportation and storage. 2. Plastic Strapping: Plastic strapping is a more cost-effective and lightweight alternative to steel strapping. It is commonly used for smaller and lighter steel coils, providing adequate strength and protection. 3. Shrink Wrapping: Shrink wrapping involves covering the steel coil with a plastic film and then applying heat to shrink and tightly seal the film around the coil. This packaging method offers protection against moisture, dust, and other contaminants. 4. Wooden Crates: Steel coils can also be packaged in wooden crates, which provide additional protection against physical damage during handling and transportation. Wooden crates can be customized to fit the specific dimensions of the coil and can be easily secured with straps or nails. 5. Coil Covers: Coil covers are large, heavy-duty plastic or fabric covers that are placed over the steel coil to protect it from environmental factors such as UV exposure, moisture, and dust. They are often used in combination with other packaging methods for added protection. 6. Paper or Fiberboard Wrapping: This packaging option involves wrapping the steel coil with paper or fiberboard material. It provides a lightweight and cost-effective solution for protecting the coil against minor scratches and abrasions. 7. Customized Packaging: Depending on the specific requirements of the customer, steel coils can be packaged using a combination of the above options or customized packaging solutions. This may include additional padding, corner protectors, or special handling instructions to ensure the safe transportation and storage of the coils. It is important for customers to consider factors such as coil size, weight, transportation mode, storage conditions, and budget when choosing the most suitable coil packaging option for their specific needs.

- Q:I'm building a single-speed commuter bike and I was wondering what the advantages and disadvantages of steel and alloy wheels are. Any experts out there who can give me specifics for each kind?

- Steel wheels are at the lowest cost and quality end of bike equipment. If you're even thinking of buying a cheapo bike with steel wheels - don't. Steel wheels are poor quality and therefore weaker than an OK alum rim. They are heavier, braking isn't as good, won't stay true as long. Alum wheels are extruded, not cast, and are better in every way. They cost more is the only down side.

- Q:What are the different types of coil slitting machines?

- There are several types of coil slitting machines, including rotary shear slitters, loop slitters, and traveling head slitters.

- Q:Can steel coils be used in the production of construction machinery?

- Yes, steel coils can be used in the production of construction machinery. Steel coils are often used as raw materials for manufacturing various components of construction machinery such as frames, chassis, gears, and structural parts. The high strength and durability of steel make it an ideal material for construction machinery, which often requires heavy-duty performance in tough working conditions. Additionally, steel coils can be easily shaped, welded, and fabricated into the desired forms and sizes, allowing for customization and versatility in the production of construction machinery.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Pre-painted Aluzinc Steel Coil Used for Industry with Good Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords