Pre-painted Aluzinc Steel Coil Used for Industry with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Pre-painted Galvanized Steel Coil Used for Industry

1.Structure of Pre-painted Galvanized Steel Coil Description

With GI as base metal, after pretreatement and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of Pre-painted Galvanized Steel Coil

•High Purity

•Easy control and operation

•High strength

•Fast melting

•Competitive price

•Best Service

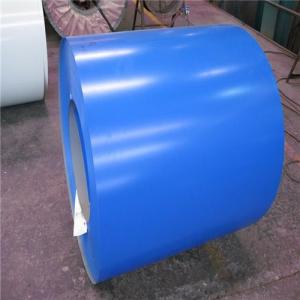

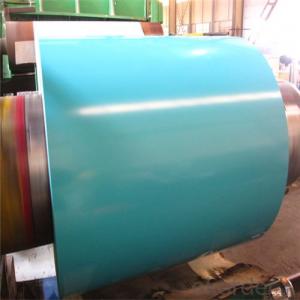

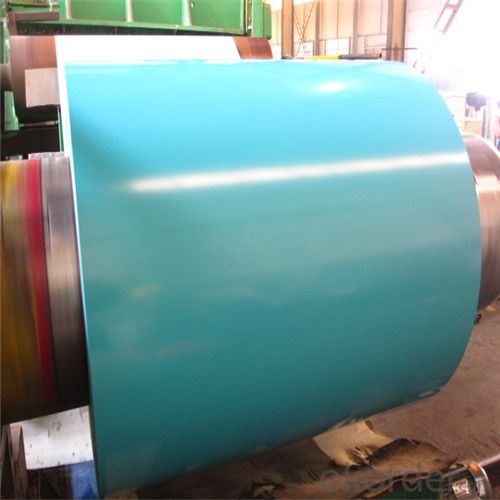

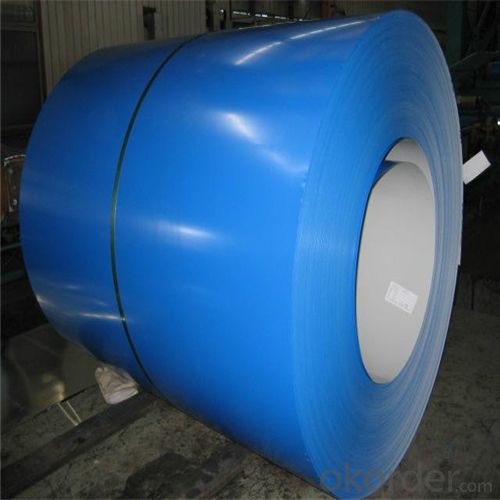

3. Pre-painted Galvanized Steel Coil Images

4. Pre-painted Galvanized Steel Coil Specification

Pre-painted Galvanized Steel Coil | |

Thicknenss | 0.18mm-1.5mm |

Width | 900-1250mm |

Coating mass | 30-275g/㎡ |

Paint | PE, PVDF, PU |

Color | RAL Scale |

Coil weight | 3-7mt |

Coil inner diameter | 508 or 610mm |

5.FAQ of Hot-Dip Galvanized Steel Coil

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory.

With GI as base metal, after pretreatement and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

- Q:How are steel coils used in the manufacturing of electrical enclosures?

- Steel coils are used in the manufacturing of electrical enclosures as they can be formed into various shapes and sizes to create the enclosure's structure. The coils are typically cut, bent, and welded together to form the walls, base, and lid of the enclosure, providing a sturdy and protective housing for electrical components.

- Q:If you were selecting a tool steel for an extreme impact load application, which one would you pick? why?thanks

- It all depends what the application actually is. For hammers I would select a hammer grade B1 steel. For impact loading where an edge is needed I would be going for O1 or similar (oil quenching steels tend to be a little tougher than air hardening). For mining tools a very high manganese steel (Hadfields steel) - this is not a true tool steel. The best place to start is by looking at the ranking of the properties which you want - hardness v toughness v strength - and then use this to put the steels in rank order. Price and availablity then sort the problem out for you (in the real world).

- Q:What is the average cost of shipping steel coils?

- The average cost of shipping steel coils can vary depending on various factors such as the distance, weight, dimensions, mode of transportation, and any additional services required. To provide an accurate average cost, it would be necessary to consider these specific details.

- Q:What are the different types of steel coil coating materials?

- Some of the different types of steel coil coating materials include polyester, polyvinylidene fluoride (PVDF), polyurethane (PU), epoxy, and silicone-modified polyester (SMP). These coatings offer various properties such as corrosion resistance, weatherability, durability, and aesthetic appeal.

- Q:How are steel coils used in the manufacturing of railway wagons?

- Steel coils are used in the manufacturing of railway wagons as they are transformed into various components such as the wagon frames, undercarriages, and body panels. These coils are processed and shaped through cutting, bending, and welding techniques to create the necessary parts for the wagons. The strength and durability of steel make it an ideal material for constructing railway wagons that can withstand heavy loads and harsh conditions on the tracks.

- Q:Can steel coils be coated with zinc-nickel alloy?

- Yes, steel coils can be coated with a zinc-nickel alloy. Zinc-nickel alloy coating provides excellent corrosion resistance and is commonly used in various industries including automotive, construction, and manufacturing.

- Q:How are steel coils used in the manufacturing of metal containers?

- Steel coils are used in the manufacturing of metal containers as they are typically unrolled and cut into specific sizes and shapes to form the body of the container. These steel coils provide strength and durability to the containers, making them suitable for storing various products such as food, beverages, chemicals, and more.

- Q:Can a steel at 0.0055 of thickness still be powerful enough to bash skulls? As well as stop handgun cartridges or at least weaken them?You see, i had an idea of making a cylindrical Knuckles made from steel. By my dimensions, 5in diameter, 12 inch h1 and 15 in h2. Half-Sphere: a sphere that is cut in half for the dome at the fist:( [ pi x ( d ^ 3) ] / 6 ) / 2Cylinder

- I don't follow your calculations. It seems to me that the piece you show could be made from .01 steel and still be less than a pound. Also, it is hard to get steel thinner than .015 because anything thinner is not very useful. If you made it out of .015 steel and used a high strength steel, it might be useful. You wouldn't be bashing any skulls, but with some spikes on the end, it could do some damage, and protect against knives or other hand weapons. You also won't get any bullet resistance out of anything that thin. If you want to bash skulls and deflect bullets, you have to get up to at least .10 and several pounds. Any weight on your hands slows down the speed of your punch, but this is compensated for by the increased energy of impact carried by the extra mass. Also, having something hard to protect your hands allows for harder hits and more damage to the opponent. An interesting idea, but it would take some testing to figure out the optimum configuration. One problem I see is that it completely encloses the hand, making it impossible to use the hand for anything else. So you would have to put it on and take it off a lot, and there would be cases where you wouldn't be able to put it on when you needed it. For that reason, I would not wear two at one time. I would make it heavier and wear it on one hand for bashing skulls and deflecting weapons, and keep the other hand free for other things.

- Q:What are the different types of steel coils available?

- There exists a variety of steel coils, each possessing distinct characteristics and uses. 1. Hot Rolled Steel Coils: These coils undergo production at high temperatures and are ideal for applications requiring a sleek and polished finish, such as automotive components, construction materials, and machinery. 2. Cold Rolled Steel Coils: In order to enhance surface finish and dimensional accuracy, these coils are processed at lower temperatures. They find extensive use in industries like automotive, appliances, and electronics, where precision is of utmost importance. 3. Galvanized Steel Coils: A layer of zinc is applied to these coils to safeguard the underlying steel against corrosion. They are commonly utilized in the construction sector, roofing, and automotive parts that are exposed to harsh environmental conditions. 4. Stainless Steel Coils: Created by combining iron, chromium, and other elements, these coils offer exceptional resistance to corrosion and possess high strength. They are widely employed in applications demanding hygiene, such as food processing equipment, medical instruments, and kitchen appliances. 5. Electrical Steel Coils: Specifically designed for applications requiring magnetic properties, these coils are utilized in transformers, electric motors, and generators. They exhibit low core losses and high permeability, ensuring efficient transfer of electrical energy. 6. Pre-painted Steel Coils: These coils are coated with paint or other protective coatings to enhance their visual appeal and provide additional protection against corrosion. They are commonly used in the construction industry for cladding, roofing, and siding. 7. Tinplate Steel Coils: A thin layer of tin is applied to these coils to prevent corrosion and act as a barrier against moisture and oxygen. They find widespread usage in the packaging industry for cans, containers, and other food or beverage packaging. These examples merely scratch the surface of the various steel coil options available in the market. Each variant possesses its own unique properties and applications, rendering them suitable for diverse industries and purposes.

- Q:How are steel coils used in the production of construction machinery?

- Steel coils are used in the production of construction machinery as they provide the raw material needed for manufacturing various components, such as frames, beams, and structural elements. These coils are processed and shaped into the desired forms, ensuring the machinery's durability, strength, and stability.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Pre-painted Aluzinc Steel Coil Used for Industry with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords