Pre-painted Aluzinc Steel Coil Used for Industry with Best Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre-painted Aluzinc Steel Coil Used for Industry

1.Structure of Pre-painted Aluzinc Steel Coil Description

With aluzinc steel as base metal, after degrease and chemical treatment and liquid dope with several layers of color, then after firing and cooling.

2.Main Features of Pre-painted Aluzinc Steel Coil

•High Purity

•Easy control and operation

•High strength

•Fast melting

•Competitive price

•Best Service

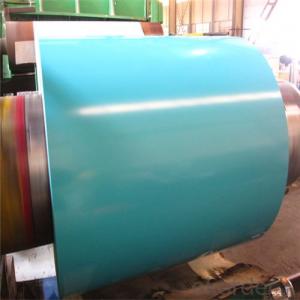

3. Pre-painted Aluzinc Steel Coil Images

4. Pre-painted Aluzinc Steel Coil Specification

Pre-painted Aluzinc Steel Coil | |

Thicknenss | 0.18mm-1.5mm |

Width | 900-1250mm |

Coating mass | 30-185g/㎡ |

Paint | PE, PVDF, PU |

Color | RAL Scale |

Coil weight | 3-7mt |

Coil inner diameter | 508 or 610mm |

5.FAQ of Pre-painted Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. So we can give you commonly 50days.

- Q:What are the different methods of cutting edge trimming for steel coils?

- There exist multiple techniques for trimming steel coils, each with unique benefits and applications. Some of the frequently employed methods are as follows: 1. Shearing: This method entails cutting the steel coil's edge using sharp blades. It is a quick and efficient technique suitable for high-volume production. However, shearing may lead to slight distortion or burrs along the cut edge. 2. Slitting: Slitting involves passing the steel coil through rotating circular blades, resulting in narrower strips. This method is commonly adopted when precise width control is necessary, such as for the production of narrow strips or coils with multiple widths. 3. Laser cutting: Laser cutting is a highly precise technique that employs a laser beam to cut through the steel coil. It offers the advantage of producing clean and precise cuts without any distortion or burrs. Laser cutting is frequently used for intricate or complex shapes that require high accuracy. 4. Plasma cutting: Plasma cutting utilizes an ionized gas jet to cut through the steel coil. It is particularly suitable for thicker materials or applications where high cutting speeds are required. Plasma cutting can generate clean and smooth cuts, although a slight bevel may be present on the edge. 5. Waterjet cutting: Waterjet cutting employs a high-pressure jet of water mixed with an abrasive substance to cut through the steel coil. This technique is highly versatile and can be used for various materials and thicknesses. Waterjet cutting is renowned for producing precise cuts without any heat-affected zone. 6. Sawing: Sawing is a traditional method that involves using a rotating saw blade to cut through the steel coil. It is commonly used for thicker materials or when a rougher cut is acceptable. Sawing can be performed manually or with the assistance of automated sawing machines. Each method possesses its own advantages and considerations, and the selection depends on factors such as required accuracy, production volume, material thickness, and desired edge quality.

- Q:What are the common methods of protecting steel coils from corrosion?

- There are several common methods used to protect steel coils from corrosion. 1. Coating: One of the most effective methods is to apply a protective coating on the surface of the steel coil. Various types of coatings such as paint, epoxy, or zinc can be used to create a barrier between the steel and the corrosive environment. These coatings provide excellent corrosion resistance and prevent moisture and oxygen from reaching the steel surface. 2. Hot-dip galvanizing: This method involves immersing the steel coil in a bath of molten zinc, which creates a thick layer of zinc coating on the surface. The zinc coating acts as a sacrificial barrier, protecting the steel from corrosion. Hot-dip galvanizing is particularly effective in harsh environments or for long-term outdoor exposure. 3. VCI (Volatile Corrosion Inhibitor) packaging: VCI packaging is a method where steel coils are wrapped in a specially designed film or paper that contains volatile corrosion inhibitors. These inhibitors vaporize and form a protective layer on the surface of the steel, preventing corrosion. VCI packaging is commonly used for short-term storage or transportation of steel coils. 4. Desiccants: Moisture is a major contributor to corrosion. Therefore, using desiccants such as silica gel or activated alumina can help absorb moisture and maintain a dry environment around the steel coils. Desiccants are often used in conjunction with other protective methods to enhance corrosion protection. 5. Proper handling and storage: Proper handling and storage practices can significantly reduce the risk of corrosion. Steel coils should be stored in a dry environment away from moisture sources. They should also be handled with clean gloves to prevent the transfer of corrosive contaminants. Regular inspection and maintenance of the storage area are essential to identify and address any potential corrosion risks. By employing one or a combination of these methods, steel coils can be effectively protected from corrosion, ensuring their durability and integrity.

- Q:How are steel coils used in the production of building systems?

- Steel coils are used in the production of building systems by being processed and shaped into various components such as beams, columns, and trusses. These coils are fed into machines that cut, bend, and mold them into the desired shapes, providing structural support and stability to the building.

- Q:How are steel coils used in the production of aerospace parts?

- Due to their strength, durability, and versatility, steel coils find extensive use in the aerospace industry for the production of aerospace parts. Made from high-quality carbon steel, these coils are formed into a coil shape, facilitating their transportation and storage. In the aerospace sector, steel coils play a crucial role in manufacturing different components, including structural parts, engine parts, landing gear, and fasteners. Specifically, steel coils are extensively employed in the fabrication of aircraft frames and fuselage structures. These coils are often cut, shaped, and welded to create the necessary structural components, which contribute to the aircraft's strength and stability. Another significant application of steel coils in aerospace production is the manufacturing of engine parts. Complex shapes are formed from the processed steel coils to produce components like turbine blades, shafts, and casings. These components must withstand high temperatures, pressure, and stress, and steel coils possess the requisite strength and heat resistance for such demanding applications. Furthermore, steel coils find utility in the production of landing gear, which supports the aircraft during takeoff, landing, and ground operations. The processed steel coils are shaped into various parts of the landing gear system, including struts, beams, and brackets. These components undergo rigorous testing and require excellent strength, toughness, and fatigue resistance, all of which are provided by steel coils. Additionally, steel coils are commonly employed in the manufacturing of fasteners essential for aerospace applications. Bolts, screws, and rivets play a crucial role in joining different components together, ensuring structural integrity and safety. Steel coils are processed and formed into the desired shapes for these fasteners, offering the necessary strength and reliability for these critical connections. In summary, steel coils are indispensable in the production of aerospace parts due to their exceptional mechanical properties and reliability. Their versatility enables various shaping and processing techniques, allowing for the creation of complex and high-performance components. By incorporating steel coils into aerospace manufacturing, the industry can ensure the production of durable, safe, and efficient aircraft.

- Q:Ok I have a neodymium magnet, stuck to my fridge holding a old bottle cap opener for my beer it works fine. At the local rummage sale there was a beautiful cap opener my freind was selling for $0.25 she said had never beenUsed it was like 40 years old it is made a stainless steel. The magnet will not stick to it. I don't understand this looked this up and certain steels are not magnetic, I tried a experiment with my compass it don't point north as should it follows the bottle opener as I move it around it. If not magnetic why is this happening? Also tried placing near another neodymium magnet with a pull of about 200 lbs. Not I tiny bit of attraction to the metal. If so why is the tiny magnet in the compass attracted to it. But not a huge powerfull magnet.

- That's interesting that it caused deflection in the compass. A lot of stainless steels may be SLIGHTLY magnetic, because they have small amounts of ferrite or alpha-iron in them. Ferrite is one of the crystal phases of steel. It has a body-centered cubic (BCC) structure and it's responsible for the magnetism of ordinary steels. Adding certain elements like nickel, manganese, or molybdenum, changes the crystal structure of the steel to a face-centered cubic (FCC) structure, which is NOT magnetic. This crystal phase is known as Austenite or gamma-iron. However most iron alloys contain some impurities that may cause the steel to be not completely transformed into the FCC austenite phase, small areas remain as ferrite.

- Q:What are the typical dimensions of a steel coil?

- The typical dimensions of a steel coil can vary depending on its specific application and industry. However, common dimensions for steel coils include a width ranging from 0.5 inches to 72 inches, and a thickness ranging from 0.010 inches to 0.625 inches. The inner diameter of the coil is usually between 16 inches and 24 inches, while the outer diameter can range from 48 inches to 72 inches.

- Q:How do steel coils contribute to the energy sector?

- Steel coils contribute to the energy sector in various ways. Firstly, steel coils are used in the manufacturing of equipment and infrastructure that is essential for energy production and distribution. For example, they are used in the construction of power plants, transmission towers, and pipelines. These structures require strong and durable materials, and steel coils provide the necessary strength and reliability. Moreover, steel coils play a crucial role in the renewable energy sector. They are used in the production of wind turbines and solar panels. Wind turbines require steel coils for their towers, while solar panels use steel frames to provide support and durability. As the demand for renewable energy sources continues to grow, the use of steel coils in this sector is expected to increase as well. Furthermore, steel coils are used in the production of electrical transformers. Transformers are vital components in the energy sector, as they facilitate the transmission and distribution of electricity. Steel coils are used to create the core of the transformer, which is responsible for the efficient transfer of electrical energy. The quality and reliability of the steel coils used in transformers are essential to ensure the smooth functioning of the electrical grid. In addition to their direct applications, steel coils also contribute to the energy sector indirectly. Steel is a recyclable material, and the recycling process consumes less energy compared to the production of new steel. By using recycled steel coils, the energy sector can reduce its carbon footprint and contribute to a more sustainable and environmentally friendly energy production process. Overall, steel coils are a vital component in the energy sector. They are used in the manufacturing of equipment and infrastructure, including power plants, transmission towers, wind turbines, solar panels, and electrical transformers. Additionally, the recyclability of steel contributes to the sustainability of the energy sector.

- Q:How are steel coils used in the manufacturing of exhaust manifolds?

- Steel coils are used in the manufacturing of exhaust manifolds as they provide the raw material for creating the manifold's structural components. These coils are typically cut, shaped, and welded to form the intricate and durable design required for efficient exhaust gas flow.

- Q:iam talking abt carbon steel of composition:-C=0.15wt% Mn=0.60wt% P=0.035wt% S=0.04wt% Cu=0.20 (min)wt%....

- The composition you mention is not a low carbon steel.The carbon and manganese content are high enough to mean that the crystal grain size will be small. A very large grain size is needed in steels for transformers,motors etc.The large grain size and lack of carbides in low silicon steels for magnetic purposes allows the easy movement of magnetic domain walls.Transformer steels typically have a carbon content of about 0.003% and 3.5%Si with the phosphorus and sulphur at a tenth of the levels you mention.The high Si content increases the electrical resistivity of the magnetic core and reduces the power loss from eddy currents(the core metal has voltages generated in it by the changing magnetic fields) and the power lost in eddy currents heats up a transformers core so it needs extra cooling;the loss is inversely proportional to the resistivity and 3.5%Si increases resistivity of iron by a very large amount.The presence of high silicon with ultra low carbon and manganese level allows the soft magnetic steels to be annealed at very high temperatures(850 to 1100deg C)without a phase change so that the crystals have 10,000 to 10,000,000 times the volume of the crystals in heat-treatable (Just)steel you mention.Fine for playing with and demonstrating electromagnetism but not as electrical engineering feedstuff.

- Q:How are steel coils inspected for yield strength?

- Yield strength inspection of steel coils involves a series of testing methods. The most commonly used method is the tensile test, where a small sample is taken from the coil and subjected to a controlled load until it reaches its yield point. In the tensile test, the sample is progressively stretched until it deforms and ultimately fractures. Throughout this process, the load and elongation data are continuously recorded. The yield strength is then determined by pinpointing the point on the stress-strain curve where the material starts showing plastic deformation or permanent elongation. Another approach to inspecting steel coils for yield strength is the hardness test. Since hardness is often linked to yield strength, a hardness test can estimate the material's yield strength. This test involves measuring the steel coil's surface resistance to indentation or penetration using instruments like a Rockwell or Brinell hardness tester. Moreover, non-destructive testing methods like ultrasonic testing and magnetic particle inspection can also be utilized to assess yield strength. Ultrasonic testing employs high-frequency sound waves to detect any internal defects or inconsistencies in the material's structure. On the other hand, magnetic particle inspection relies on the application of magnetic fields and the usage of magnetic particles to identify surface cracks or defects. In conclusion, there are various testing methods available to inspect steel coils for yield strength. These methods offer valuable information to manufacturers and inspectors regarding the steel's quality and performance capabilities, ensuring that it meets the required standards and specifications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Pre-painted Aluzinc Steel Coil Used for Industry with Best Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords