PPR Pipe Plastic Pipes Energy-saving Materials

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

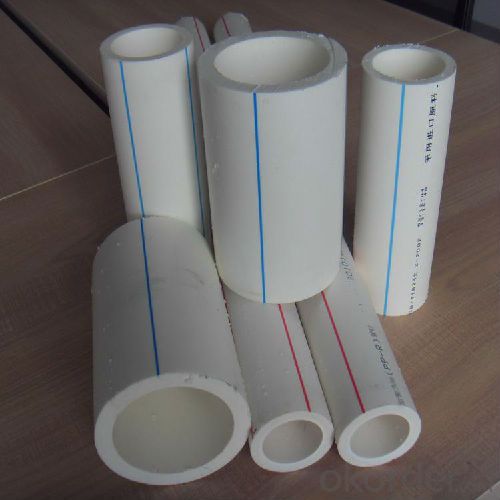

PP-R pipe by using the random copolymer polypropylene extruded into pipe, injection molded into the pipe, the company's specifications and diverse options, white, gray, green

Main Features of PPR Pipe

PPR pipe called three polypropylene tube and called random copolymer polypropylene tube or pipe PPR, which has energy-saving materials, environmental protection, high-strength lightweight, corrosion-resistant, smooth wall does not scale, simple construction and maintenance, service life long, it is widely used in building water supply and drainage, urban and rural construction, municipal, industrial and agricultural areas of water supply and drainage, city gas, electricity and cable jacket, industrial fluid transport, agriculture and irrigation.

Pictures of PPR Pipe

- Q:Manual ball valve type: Class400, 20 ', what does that mean, industrial knowledge?

- The pressure rating of the valve type and American StandardIt's a 20 inch, 400 pound valve20 inch =DN500 (nominal diameter)400 pounds equivalent to nominal pressure PN64 Mpa

- Q:Is the integral type split ball valve structurally identical?

- Split type ball valve, the valve body by the main body and the cover body is composed of two parts, thread connection between the main body and the cover body is arranged at the connection of the sealing ring, an annular sealing ring and ball valve, valve rod, sealing gasket, valve stem nut, a handle, a fastening nut is arranged on the main body, there is another ring the sealing ring is arranged on the cover body, interface screw holes at both ends of the valve body are respectively processed in the main body and cover body. This structure of the ball valve, the ball cavity depth is relatively shallow, the ball cavity processing is more convenient.

- Q:Stainless steel ball valve, Q11F-10P, 16P, 11F, what does that mean?

- Q11F-10P 16P is the meaning of stainless steel internal thread ball valve. One is 10 kilograms, one is 16 kilogramsQ valve Code: ball valveManual no code representation1 connection: internal thread1 structure form: floating through typeF sealing material: fluoroplastic10 valve pressure: 10 kg 1.0MPa 16=1.6mpaP body material: stainless steel

- Q:What's the difference between a copper ball valve and a stainless steel ball valve?

- The difference between copper ball valve and stainless steel ball valve:1, they use the material is completely different, steel ball valve adopts copper, stainless steel ball valve is stainless steel.2, copper ball valve corrosion resistance is excellent, switch operation is smooth, labor-saving, durable without leakage. Stainless steel will not cause corrosion, pitting corrosion, corrosion or wear, and high temperature resistance. The average stainless steel is more expensive.3, according to the same pressure environment, the price is stainless steel cheaper, and copper ball valve medium temperature is much higher than the stainless steel ball valve, if the medium temperature is too high. Copper ball valve must be used! If the medium temperature is not more than 80 degrees. With stainless steel ball valve on it

- Q:Daily maintenance of ball valve

- Longer service life and maintenance free period will depend on several factors: normal working conditions, maintaining a consistent temperature / pressure ratio, and reasonable corrosion dataBall valve in the closed state, there is still pressure fluid inside the valve bodyRemove the line pressure before servicing and leave the valve in the open positionDisconnect the power or air supply before servicingBefore the maintenance, remove the actuating mechanism from the bracketMust be found on the ball valve, the downstream pipeline has been removable pressure, in order to disassemble, disassemble operationIt is important to be careful not to damage the sealing surfaces of the parts, especially non-metallic parts, to remove the O rings. Use special tools when taking apart and re assemblingWhen assembling, the bolts on the flange must be symmetrical and tightened gradually and evenlyThe cleaning agent should be compatible with rubber, plastic, metal parts and working medium (such as gas) in the ball valve. When the working medium is gas, the metal parts can be cleaned by using gasoline (GB484-89). Non metallic parts are cleaned with pure water or alcoholThe non-metallic parts should be removed from the cleaning agent immediately after cleaning and should not be soaked for a long timeNeed to be cleaned by washing the wall after volatile cleaning agent (cleaning agent can not dip silk rub) for assembly, but not for a long time on hold, otherwise it will rust, dust pollution

- Q:What is the ball valve core?

- The ball (ball valve as the cut-off valve in the marine and marine field), standard GB/T21465-2008 "valve terminology" is defined as: opening and closing parts (ball) driven by the stem, and around the valve axis for rotation of the valve. Can also be used to regulate and control fluid, strong shear force between the metal seat seal V type ball valve V type ball core and welding hard alloy, especially suitable for containing fibers, small solid particles and other media. Switch and multi way valve in the pipeline not only can flow, and flow diversion, flexible control of the medium, but also to turn off any channel to the other two channels. This kind of valve should be installed horizontally in the pipeline. In accordance with the way to drive the ball valve is divided into: pneumatic ball valve, electric ball valve, manual ball valve.

- Q:Hello, I would like to ask the household tap water valve selection of stainless steel ball valve or brass ball valve is better, thank you

- I have used two kinds, but stainless steel gate valve is better. Note that it must be made of stainless steel 304. I bought more than 300 yuan a gate valve. Total valve, no way to save money.

- Q:What is the ball valve Q11F -16 material?

- If sealed, F stands for fluoroplastic. Valve material is not marked in the model!Q stands for ball valvesThe first 1: threaded connection,Second 1: is the ball valve is floating through the ball,F stands for PTFE- PTFE seals16 represents the nominal pressure of the ball valve is 1.6MPa=16 kg

- Q:What are the differences between the pneumatic ball valve and the pneumatic angle seat valve?

- Pneumatic angle seat valve is the use of reciprocating actuators, usually in use to withstand fluid work pressure at 1.6MPa. Pneumatic ball valve is to use rotary actuator, to bear high fluid pressure. In normal use, the reciprocating actuator is characterized by its service life over the length of the rotary actuator. Two: easy maintenance. Three: the price is cheap. Personal recommendations in fluid pressure below 1.6MPa, or pneumatic angle seat valve is better?. High pressure, less opening frequency, pneumatic ball valve is appropriate.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PPR Pipe Plastic Pipes Energy-saving Materials

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords