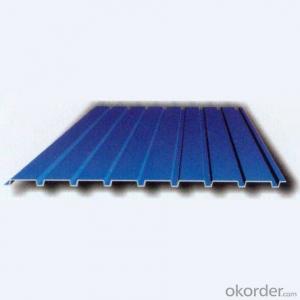

PPGL steel sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Detail: | seaworthy expot package for Corrugated roofing steel |

| Delivery Detail: | on request for Corrugated roofing steel |

Specifications

Corrugated roofing steel

1.10 year's experience

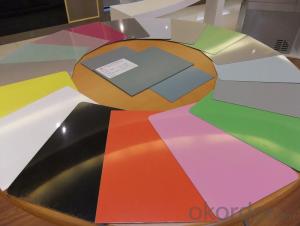

2. advanced coating equipment

3.competitive price

4.various color

- Q:What is the bending radius for steel sheets?

- The bending radius for steel sheets depends on various factors such as the thickness of the sheet, the type of steel being used, and the specific application. Generally, a common rule of thumb is to use a bending radius that is at least twice the thickness of the steel sheet. However, this value may vary depending on the specific requirements and limitations of the project. It is important to consult with engineering and fabrication professionals who have expertise in working with steel sheets to determine the appropriate bending radius for a given application.

- Q:What are the standard dimensions of steel sheets?

- The standard dimensions of steel sheets vary depending on the specific application and industry requirements. However, common standard dimensions for steel sheets range from 4 feet by 8 feet (1.2 meters by 2.4 meters) to 5 feet by 10 feet (1.5 meters by 3 meters).

- Q:What are the different sheet metal folding techniques for steel sheets?

- There are several sheet metal folding techniques for steel sheets, including the following: 1. V-Bending: This technique involves bending the sheet along a V-shaped groove. The sheet is placed between a punch and a die, and as the punch descends, it forces the sheet into the die, creating the desired bend. 2. Edge Bending: Also known as flanging, edge bending involves bending the edges of the sheet to form a flange. This technique is commonly used for joining two or more sheets together or creating a stiffening edge. 3. Box Folding: Box folding is used to create 3D shapes, such as boxes or enclosures. It involves folding the sheet along multiple bends to form a hollow structure. 4. Hemming: Hemming is a technique used to create a folded edge on the sheet, typically for aesthetic purposes or to provide additional strength. It involves folding the edge of the sheet back onto itself. 5. Roll Bending: Roll bending is a technique used to achieve curved bends in the sheet. The sheet is passed through a series of rollers, which gradually bend it to the desired curvature. These are just a few of the most commonly used sheet metal folding techniques for steel sheets. The choice of technique depends on the specific requirements of the project and the desired outcome.

- Q:How do steel sheets perform in high-humidity environments?

- Steel sheets perform well in high-humidity environments due to their corrosion-resistant properties. The steel's protective coating prevents moisture from penetrating the surface, minimizing the risk of rust and deterioration. However, it is essential to ensure proper maintenance and ventilation to prevent condensation buildup and potential damage over time.

- Q:Are steel sheets suitable for HVAC systems?

- Yes, steel sheets are suitable for HVAC systems. Steel sheets are commonly used in HVAC systems due to their durability, strength, and resistance to corrosion. They provide structural integrity to the system and can withstand high temperatures and pressure. Additionally, steel sheets are easy to fabricate and can be customized to fit specific HVAC system requirements. They are also cost-effective and have a long lifespan, making them a preferred choice for HVAC system components such as ductwork, ventilation systems, and air handling units.

- Q:Can steel sheets be used in food processing or medical applications?

- Yes, steel sheets can be used in food processing and medical applications. Stainless steel sheets, in particular, are commonly utilized in these industries due to their corrosion resistance, durability, and hygienic properties. They are often used for manufacturing equipment, such as food processing machinery, surgical instruments, and medical devices, as they can withstand high temperatures, resist contamination, and are easily cleanable.

- Q:What is the difference between a painted and powder coated steel sheet?

- The application process and resulting finish distinguish painted steel sheets from powder coated steel sheets. Painted steel sheets are typically covered with a liquid paint, which can be applied through various methods such as spraying, brushing, or dipping. This liquid paint contains pigments and binders that stick to the steel surface and create a protective layer. It is possible to customize the paint in terms of color, gloss, and texture, allowing for a multitude of design options. However, painted surfaces may be susceptible to chipping, peeling, and fading over time, especially in harsh environments or with exposure to UV radiation. On the other hand, powder coated steel sheets are coated with a dry powder, which is electrostatically administered to the steel surface. The powder consists of a blend of finely ground particles, including pigments, resins, and additives. When applied, the steel sheet is heated, causing the powder particles to melt and fuse together, resulting in a sturdy and consistent coating. The outcome is a smooth, uniform finish that offers exceptional resistance to chipping, scratching, and UV radiation. Powder coating also provides a wider range of color choices and finishes compared to traditional liquid paint. In conclusion, although both painted and powder coated steel sheets offer protection and aesthetic appeal, powder coating provides superior durability, damage resistance, and a broader range of design possibilities.

- Q:Can steel sheets be galvanized?

- Yes, steel sheets can be galvanized. Galvanizing is a process of coating steel with a protective layer of zinc, which helps to prevent corrosion and extend the lifespan of the steel sheets.

- Q:Can steel sheets be used for making furniture?

- Yes, steel sheets can be used for making furniture. Steel is a versatile material that offers several advantages when used for furniture construction. It is known for its strength, durability, and ability to withstand heavy loads. Steel sheets can be shaped, welded, and fabricated into various furniture pieces such as tables, chairs, cabinets, and even bed frames. Additionally, steel furniture tends to be resistant to rust and corrosion, making it suitable for both indoor and outdoor use. The sleek and modern aesthetic of steel also adds a contemporary touch to any space.

- Q:How do you prevent rust on steel sheets?

- To prevent rust on steel sheets, it is essential to apply a protective coating such as paint or a corrosion-resistant finish. Additionally, keeping the steel sheets dry and avoiding exposure to moisture and humidity can significantly reduce the chances of rust formation. Regular cleaning and maintenance, including the removal of any existing rust, also help in preventing its further spread and maintaining the steel sheets' integrity.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PPGL steel sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords