PPGI Prepainted Galvanized Steel Roof Sheets in Coils

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

PPGI Prepainted Galvanized Steel Roof Sheets in Coils

Details of PPGI Prepainted Galvanized Steel Roof Sheets in Coils

Grade | DX51D, SGCC, CGCC |

Thickness | 0.15mm-1.5mm |

Width | 600mm-1500mm(914/1219/1250 are available) |

Standard | JIS G3312, ASTM,GB/T1275 |

Certificate | ISO9001.ISO14001.OHSAS18001 |

Length | As per requests |

Zinc Coating | 40g-275g/m2 |

Lacquer Coated | 20-25 microns/5-15 microns |

Coil ID | 508mm/610mm |

Coil Weight | normally 3-10mt or as your requirement |

Supply ability | 200,000Mt/year (MOQ:25Mt) |

Color | RAL No. |

Price terms | FOB,CFR,CIF |

Payment terms | L/C,T/T |

Deliver time | 30days after received deposit or L/C |

Packing | Standard exporting package |

steel strip Water proof paper, metal covers, | |

Application | Corrugated roofing,outside building, |

boating building,car producing | |

household appliance | |

Main market | Southeast Asia , the EU, Russia, Ukraine , Latin America and other countries and Regions |

Specification of PPGI Prepainted Galvanized Steel Roof Sheets in Coils

Thickness | Width | Length of plate | Inner diameter of coil |

0.18-1.2mm | 800/914/1000/1200/1219/1250mm | 1000-6000mm | 508mm/610mm |

Coated Mass: | |||

Available Coated Mass(g/m^2) | Base plate | Available Coated Mass(g/m^2) | |

60,80, 100, 120, 160, 180 | Galvanized Steel | 60,80, 100, 120, 160, 180 | |

50, 70, 150 | Galvalume Steel | 50, 70, 150 |

Painting | Item | Code | |

Polyester | PE | ||

High-durability polyester | HDP | ||

Silicon modified polyesters | SMP | ||

Polyvinylidene fluoride | PVDF | ||

Easy-Cleaning | — | ||

Painting Thickness | Top side: 20±5microns; | ||

Bottom side: 5~7microns. | |||

Color System | Produce according to RAL Color System or as per buyer’s color sample. | ||

Painting structure | Top surface | Bottom surface |

|

Primer coating | No coating | 1/0 | |

Primer coating | Primer coating | 1/1 | |

Primer coating + Finish coating | No coating | 2/0 | |

Primer coating + Finish coating | Primer coating or single back coating | 2/1 | |

Primer coating + Finish coatin | Primer coating + Finish back coating | 2/2 | |

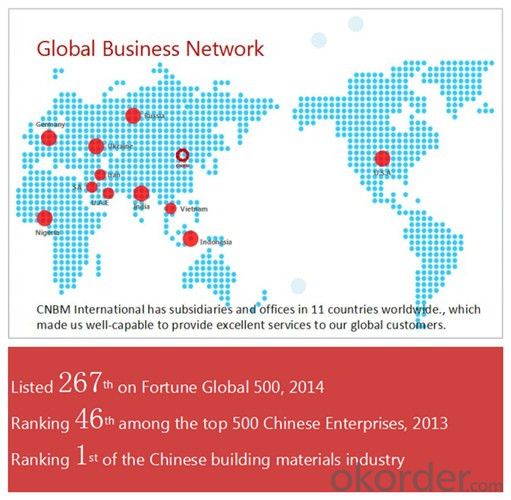

CNBM Introduction of PPGI Prepainted Galvanized Steel Roof Sheets in Coils

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery of PPGI Prepainted Galvanized Steel Roof Sheets in Coils

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

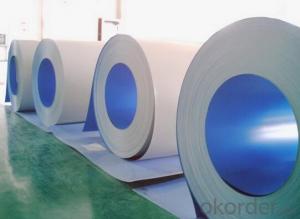

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q:What are the specific requirements for special steel used in the oil and gas pipeline industry?

- The specific requirements for special steel used in the oil and gas pipeline industry are dictated by the harsh operating conditions and the need for high performance and reliability. Some of the key requirements include: 1. Corrosion resistance: Special steel used in the oil and gas pipeline industry must possess excellent resistance to corrosion, as pipelines are exposed to various corrosive elements such as moisture, gases, and chemicals. This helps to prevent the degradation or failure of the pipeline due to corrosion. 2. High strength: The steel used in pipelines must have high tensile strength to withstand the high pressure and stress that it experiences during transportation of oil and gas. This ensures the pipeline's structural integrity and prevents leaks or bursts. 3. Toughness and impact resistance: The steel must be able to absorb energy and resist fracture when subjected to sudden impact or external forces. This is crucial for maintaining pipeline integrity and preventing accidents or ruptures. 4. Low temperature toughness: As pipelines often operate in cold environments, the steel must exhibit excellent low-temperature toughness to prevent brittle fracture. This ensures that the pipeline remains ductile and resistant to failure even at extremely low temperatures. 5. Weldability: Special steel used in pipelines should be easily weldable to facilitate the construction and repair of pipelines. Good weldability ensures strong and reliable joints that can withstand the stress and pressure during operation. 6. Resistance to hydrogen-induced cracking: Steel used in the oil and gas pipeline industry should have high resistance to hydrogen-induced cracking (HIC) and sulfide stress cracking (SSC). These types of cracks can occur when hydrogen or sulfide ions penetrate the steel, leading to catastrophic failure. Resistance to these types of cracking is crucial for pipeline safety. 7. Compliance with industry standards: Special steel used in the oil and gas pipeline industry must meet specific industry standards and regulations. These standards ensure that the steel meets the required mechanical properties, chemical composition, and manufacturing processes necessary for safe and reliable pipeline operation. Overall, the specific requirements for special steel used in the oil and gas pipeline industry are aimed at ensuring corrosion resistance, high strength, toughness, low-temperature performance, weldability, resistance to cracking, and compliance with industry standards. These requirements are essential for maintaining the integrity and safety of oil and gas pipelines.

- Q:What is the chemical composition of special steel?

- Special steel is a type of steel that is specifically manufactured for particular applications, and its chemical composition varies depending on its intended use. However, some common elements found in special steel include iron, carbon, manganese, chromium, nickel, and molybdenum. The precise combination and quantities of these elements are carefully balanced to achieve specific properties such as enhanced strength, corrosion resistance, or heat resistance, making special steel ideal for specialized applications in industries like aerospace, automotive, and construction.

- Q:What are the limitations of special steel in certain applications?

- Special steel, although highly versatile and durable, does have certain limitations in certain applications. One limitation of special steel is its high cost. Special steel is typically more expensive to produce compared to regular steel due to the addition of various alloying elements. This can make it less economically viable for certain applications where cost is a significant factor, especially in large-scale projects or industries with tight budgets. Another limitation is its susceptibility to corrosion. While special steel is generally more resistant to corrosion compared to regular steel, it is still not completely immune to the effects of corrosion. In environments with high levels of moisture, chemicals, or extreme temperatures, special steel may still corrode over time if not properly protected or maintained. Special steel also has limitations in terms of formability and workability. Due to its higher strength and hardness, special steel can be more challenging to shape, bend, or weld compared to regular steel. This can limit its use in applications that require complex or intricate designs, as well as those that involve extensive fabrication or assembly processes. Furthermore, special steel may have certain limitations in terms of availability and supply chain. Not all types of special steel may be readily available in the market, especially in remote or less developed regions. This can make it difficult to source the required special steel for specific applications, leading to potential delays or compromises in project execution. Lastly, the specialized properties of special steel may not always be necessary or advantageous for certain applications. In some cases, regular steel or alternative materials may be more suitable and cost-effective, especially if the specific properties of special steel are not required for the intended use. Overall, while special steel offers numerous benefits and advantages, it is important to consider its limitations in certain applications. Careful evaluation of the specific requirements, cost-effectiveness, and availability of special steel is essential to ensure its successful and optimal use in any given situation.

- Q:How is silicon steel used in electrical transformers?

- Silicon steel is used in electrical transformers due to its unique magnetic properties. It has a high electrical resistance, low coercivity, and high magnetic permeability, making it an ideal material for the cores of transformers. The silicon content in the steel reduces the eddy current losses, enhancing the efficiency of the transformer. Additionally, the laminated structure of silicon steel helps to minimize the formation of eddy currents, further improving the performance and reducing energy losses in transformers.

- Q:How does special steel perform in terms of hardness?

- Special steel performs exceptionally well in terms of hardness. Due to its unique alloy composition and precise manufacturing process, it exhibits superior hardness compared to conventional steel. This enhanced hardness allows special steel to withstand high pressures, resist wear and tear, and provide excellent performance in demanding applications across various industries.

- Q:What is the hardness range of special steel?

- The hardness range of special steel can vary depending on the specific alloy and heat treatment, but generally it falls between 50 and 70 on the Rockwell C hardness scale.

- Q:What are the specific requirements for special steel used in the textile machinery industry?

- The specific requirements for special steel used in the textile machinery industry can vary depending on the specific application and machinery involved. However, there are some general requirements that are common in this industry. 1. Corrosion resistance: Textile machinery is often exposed to moisture, chemicals, and other corrosive substances. Therefore, the special steel used in this industry must have excellent corrosion resistance properties to ensure durability and longevity. 2. High strength: Textile machinery operates under high loads and stresses. Hence, the special steel used must have high strength to withstand these forces and prevent any deformation or failure. 3. Wear resistance: Textile machinery involves constant contact between different components, resulting in wear and tear. Therefore, the special steel used should have good wear resistance properties to minimize the effects of friction and prolong the lifespan of the machinery. 4. Heat resistance: Textile machinery often operates at high temperatures due to the friction generated during the manufacturing process. The special steel used should have excellent heat resistance to prevent any deformation or loss of mechanical properties under high temperature conditions. 5. Machinability: The special steel used in the textile machinery industry should be easily machinable to allow for the production of complex components with precise dimensions. This ensures that the machinery operates smoothly and efficiently. 6. Cost-effectiveness: While meeting all the above requirements, it is essential for the special steel used in the textile machinery industry to be cost-effective. Manufacturers aim to balance the performance and cost to ensure that the machinery remains competitive in the market without compromising on quality. It is important to note that these requirements can vary depending on the specific application within the textile machinery industry. Therefore, it is crucial for manufacturers and engineers to carefully evaluate the requirements of their machinery and select the appropriate special steel accordingly.

- Q:How is special steel produced?

- Special steel is produced through a meticulous process known as alloying, where different metals are combined with iron to enhance its properties. The alloying elements are carefully selected and added to molten iron, followed by precise temperature control and cooling to form the desired steel composition. This process ensures that special steel possesses superior strength, hardness, corrosion resistance, and other unique characteristics required for specialized applications.

- Q:What are the different methods of joining special steel components?

- There are several methods of joining special steel components, each with its own advantages and applications. Some of the most common methods include welding, brazing, soldering, and mechanical fastening. 1. Welding: Welding is one of the most widely used methods for joining special steel components. It involves melting the base metals and adding a filler material to create a strong bond. Different welding techniques, such as arc welding, gas welding, or laser welding, can be used depending on the specific requirements and properties of the steel components. 2. Brazing: Brazing is a joining process that uses a filler material with a lower melting point than the base metals. The filler material is heated and distributed between the components, creating a strong bond when it solidifies. Brazing is often used for high-temperature applications and can be done with a torch, furnace, or induction heating. 3. Soldering: Soldering is similar to brazing but uses a lower melting point filler material called solder. It is commonly used for electrical and electronic applications, as well as for joining small or delicate steel components. Soldering requires less heat and can be done with a soldering iron or a hot air gun. 4. Mechanical Fastening: Mechanical fastening involves joining components using mechanical means such as screws, bolts, nuts, or rivets. This method is often used when disassembly or reassembly is required, as it allows for easy removal and replacement of components. Mechanical fastening is suitable for applications where a strong and reliable joint is needed but welding or brazing may not be feasible. 5. Adhesive Bonding: Adhesive bonding is another method used for joining special steel components. It involves applying an adhesive material to the mating surfaces and allowing it to cure or harden, creating a strong bond. Adhesive bonding is often used when a continuous joint is required or when joining dissimilar materials. It is also advantageous for applications that require vibration damping or sealing. Each method of joining special steel components has its own strengths and limitations, and the selection of the appropriate method depends on factors such as the specific requirements of the application, the properties of the steel components, and the desired strength and durability of the joint.

- Q:How does special steel contribute to the telecommunications equipment industry?

- The telecommunications equipment industry greatly relies on special steel to support its complex infrastructure and advanced technologies. Special steel plays a critical role by providing the necessary strength, durability, and reliability. An important aspect of special steel is its ability to withstand extreme weather conditions and environmental factors. Telecommunications equipment, such as transmission towers, antennas, and satellites, often face harsh elements like strong winds, heavy rain, and earthquakes. Special steel, with its high tensile strength and resistance to corrosion, ensures the stability and longevity of the infrastructure, minimizing the risk of damage or failure. Additionally, special steel is used in the production of various components for telecommunications equipment. Connectors, cables, and electronic enclosures, for example, require materials with excellent electrical conductivity and heat dissipation properties. Special steel alloys, including stainless steel or nickel-based alloys, are utilized to meet these requirements, ensuring efficient signal transmission and preventing overheating issues. Furthermore, special steel is crucial for manufacturing high-quality tools and equipment used in the installation, maintenance, and repair of telecommunications networks. Specialized steel alloys, such as tool steel, provide exceptional hardness, toughness, and wear resistance, enabling the production of reliable and long-lasting tools. These tools are essential for professionals in the telecommunications industry as they allow for efficient and accurate installation and maintenance, ensuring uninterrupted connectivity for end-users. Moreover, as the telecommunications industry continues to advance, special steel is vital in supporting the deployment of advanced technologies like 5G networks and fiber-optic systems. These technologies require specialized components, such as waveguides, reflectors, and amplifiers, often made from special steel alloys to ensure optimal performance and durability. By providing the necessary materials for these cutting-edge technologies, special steel contributes to the expansion and enhancement of telecommunications infrastructure worldwide. In conclusion, special steel is indispensable to the telecommunications equipment industry due to its strength, durability, and reliability, which are crucial for infrastructure, components, tools, and advanced technologies. Its unique properties enable the industry to provide efficient and uninterrupted communication services to individuals and businesses globally.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PPGI Prepainted Galvanized Steel Roof Sheets in Coils

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords