PPGI,Pre-Painted Steel Coil/Sheet with Prime Quality White Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

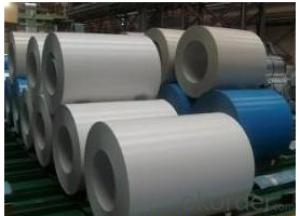

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q:How are steel coils inspected for weldability using welding tests?

- Steel coils can be inspected for weldability using a variety of welding tests. One common method is the bend test, where a section of the coil is cut and bent to evaluate the quality of the weld. This test helps determine if the weld is brittle or contains any defects that could compromise its integrity. Additionally, the guided bend test is performed to assess the ability of the weld to withstand bending without cracking or breaking. Another technique used is the macro etch test, where a sample is prepared by cutting a cross-section of the coil and then etching it with a chemical solution. This test helps reveal any imperfections or inconsistencies in the weld, such as porosity, slag inclusions, or lack of fusion. Furthermore, the hardness test is conducted to measure the hardness of the weld. This is important as excessive hardness can lead to cracking or brittleness, while insufficient hardness may result in weld failure under certain conditions. Additionally, non-destructive testing methods like ultrasonic testing, magnetic particle inspection, or radiographic examination can also be employed to detect any internal defects, such as cracks or voids, in the steel coil welds without damaging the material. These welding tests are crucial in ensuring the quality and weldability of steel coils before they are used in various applications. By conducting thorough inspections, any potential issues can be identified and addressed, ensuring that the steel coils meet the required standards for weldability and structural integrity.

- Q:What are the various surface finishes available for steel coils?

- The various surface finishes available for steel coils include hot-rolled, cold-rolled, galvanized, coated, and polished finishes.

- Q:Can i use steel shot in a remington 870 wingmaster full choke 30 inch barrel. the shotgun is in great shape and about 20 or 25 years old probably. thank you. the steel shot i have got is 12 gauge 2 3/4 in 1550 velocity 1 1/16 oz 2 shot winchester xpert high velocity steel shot

- Because of environmental concerns steel, bismuth and tungsten is replacing lead shot, for bird hunting. The problem with steel shot is the hardness, which can cause damage to the bore and choke in older shotguns. Unlike lead there is no give to steel and it can damage the bore especially if the choke is on full. Tungsten is also very hard, but it is often alloyed with other metals making it softer causing less damage in older models shotguns. Bismuth falls in between tungsten and steel, being the softer of the two by far.

- Q:I know the law regarding selling steel core ammo, but is it possible to buy a steel core bullet and load it yourself?

- I don't ever recall seeing reloading components listed as steel core but I guess they could be out there. Why on earth would you want to load steel core if regular projectiles are available?

- Q:What is the cost of steel coils?

- The cost of steel coils can vary depending on factors such as size, quality, and market conditions. It is best to contact a supplier or check current market prices to get an accurate cost.

- Q:Can you recycle steel? And if you wanted to buy some recycled steel, where would you get it?

- Hi, You bet ya.Right now its the big boom here in Maine.A lot of people are doing it ,its a good thing cause its helping clean up a lot of the junk around here. You could go to a scrap yard But I don't think they would seel much right now they are busier then ever just bringing in stuff. Anyways if you really got a lot let me know I can tell you everything you need to know and what to do with what you got. Mike

- Q:How are steel coils inspected for width using laser measurement?

- Steel coils are inspected for width using laser measurement by placing a laser sensor on one side of the coil and a reflective target on the other side. The laser beam is emitted towards the target, and the reflected beam is analyzed by the sensor. Based on the time it takes for the beam to travel back and the angle of the beam, the width of the steel coil can be accurately measured.

- Q:How are steel coils used in the manufacturing of braking systems?

- Steel coils are used in the manufacturing of braking systems as they are shaped and formed into various components such as brake discs, brake pads, and brake calipers. These coils are made of high-quality steel that provides strength and durability, ensuring efficient and reliable braking performance for vehicles.

- Q:How are steel coils used in the manufacturing of electrical transformers?

- Steel coils are used in the manufacturing of electrical transformers as they provide structural support and act as a core for the transformer. The steel coils are wound with copper wire to create the primary and secondary windings, which help in transferring electrical energy efficiently.

- Q:rust is not a issue. i was looking a D2 steel but heard story's of it chipping and breaking

- INFI steel used by Busse Combat is probably one of the best steels around right now, but the price reflects that. The heat treat is a HUGE part of the toughness of a steel. A good heat treat can make a bad steel a good one, or a good one a great one. I personally prefer 1095. It's a good ole tool steel on the lower end of the price scale and it holds up well. I've always had good experiences with 1095.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PPGI,Pre-Painted Steel Coil/Sheet with Prime Quality White Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords