PPGI/Pre-Painted Galvanized Steel Coil/Construction Purposes Az80-Az140

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

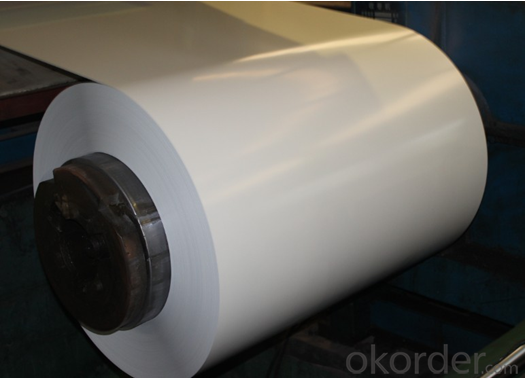

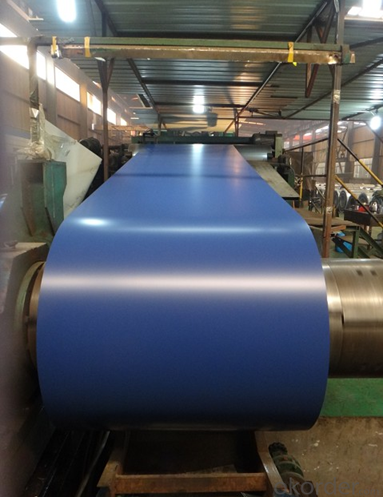

Pre-Painted Galvanized Steel Coil/Construction Purposes Az80-Az140

Product Description

Product Name: China PPGI manufacturer/PPGI MILL

PPGI coils

PPGI steel coils

PPGI galvanized coils

PPGI zinc coated coils

Pre-painted galvanized steel coils

Color coated steel coils

Color coated steel coils

Red color/blue color steel coils

Color coated PPGI FOR metal roof

DX51D color coated corten steel coil(PPGI)

Prime prepainted galvanized steel coil

White color prepainted steel coils

Color steel coil for roofing material

Dx51d+z prepainted steel coil

Colorful galvanized steel coil

Specifications:

Grades: Q195-Q235 and SPCC, SPCD, SPCE, SGCC (DX51D+Z) and SGCD (DX52D+Z)

Thickness: 0.13 to 2.0mm

Width: 600 to 1200mm or customized

Coil inner diameter: 508 to 610mm

Coil weight: Customized

Color: RAL

Surface protection: PE, PVDF, SMP and HDP

Surface treatment: Chromate, oil/un-oil, bright finish, spangle and anti-finger print

Standards: JIS G3302, JIS G3312 and ASTM A653M/A924M 1998

Zinc coating weight: 60 to 275G/M

Features:

Nice corrosion-resistant: Zinc layer provides nice protection of pre-painted galvanized steel sheet

High heat resistant: Reflective surface of material aids in efficiently reflecting sunlight away and turn reducing amount of heat transmitted, thermal reflectivity converts into energy-saving.

Coating adhesive force of color-coated sheet is strong, which keeps color and luster novel for long.

Widely used in such field as architecture, electrical home appliances, furniture, communal facilities, communications and transportation.

PPGI prepainted sheets and coils

Product thickness: 0.135 to 2.0mm

Product width: 760 to 1250mm

Coil weight: 5 to 10 metric tons

Coil ID: 508mm

Coil OD: Max 1500mm

Coating type: PE

Standards: JIS G 3312, ASTM A755M, GB/T 12754, Q/CHG 2-2003, EN 10143, DIN 17162

Material: TDC51D, AZ150, SGCC, CGCC, SPCC195L, TSGCC, CCGI, Q195-Q235, SPCD, SPCE

Color: RAL

Zinc coating: 60 to 275G/M²

Application: Construction, hardware, home appliances, interior decoration and more.

NAME | PPGI | GALVANIZED | GALVALUME/ALUZINC |

CERTIFICATE | ISO9001:2008 | ||

| EN10142 | ASTM A653 | ASTM A792 |

| CGCC | SS GRADE33-80 | GRADE33-80 |

MODEL NO | 0.16MM-1.5MM*1250MM OR UNDER | (0.12-1.5)*1250MM OR UNDER | 0.16MM-1.5MM*1250MM OR UNDER |

| Steel coil | Steel coil | Steel coil |

| Hot rolled-cold rolled | Hot rolled-cold rolled | Hot rolled-cold rolled |

SURFACE | Mini/regular/big/zero spangle, | Mini/regular/big/zero spangle, | |

APPLICATION | Structural use ,roofing, commercial use, household appliance, industry, family | ||

SPECIAL | Wear resistant steel, high- strength - steel plate | ||

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

4.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

- Q:okay i got some questions of the steel plow.1st - who inveneted it? where and when?2nd - how did it work? what is it used for? what is it made of? how is it produced?okay guys thank you very much. remember best answer gets best answer 10 points!

- You want ot read up on American John Deere; he madethe first plow capable of cutting the virgin sod of the great planes.

- Q:What are the common applications of coated steel coils?

- Some common applications of coated steel coils include manufacturing of automotive parts, construction materials such as roofing and siding, appliances, and electrical equipment. They are also used in the production of household goods such as furniture, shelving, and storage racks. Additionally, coated steel coils find applications in the transportation industry for manufacturing trailers, shipping containers, and railway cars due to their durability and corrosion resistance.

- Q:Does a magnet stick to galvinied steel?

- yes it does. The steel below the galvanized coating still has a relative high carbon content and magnets stick to it. Magnets do not stick to stainless steel very well though. There is a weak attraction there. If I recall correctly this is due to the relatively low carbon content and the higher content of chromium.

- Q:What are the quality control measures for steel coil production?

- Quality control measures for steel coil production typically include: 1. Raw Material Inspection: Ensuring the quality and specifications of the raw materials used for manufacturing steel coils, such as checking the chemical composition, dimensions, and mechanical properties. 2. Process Control: Monitoring and controlling various stages of the steel coil production process, including heating, rolling, cooling, and coating to ensure consistent quality and adherence to specifications. 3. Dimensional Checks: Conducting regular inspections to verify the dimensions, thickness, width, and length of the steel coils, ensuring they meet the required standards. 4. Surface Inspection: Checking the surface quality of the steel coils for any defects, such as scratches, dents, or blemishes, that may affect their performance or appearance. 5. Mechanical Property Testing: Conducting tests to determine the mechanical properties of the steel coils, such as tensile strength, yield strength, elongation, hardness, and impact resistance, to ensure they meet the desired specifications. 6. Coating Inspection: Verifying the quality and thickness of any coatings or finishes applied to the steel coils, such as galvanization or painting, to ensure corrosion resistance and aesthetic appeal. 7. Packaging and Labeling: Ensuring proper packaging and labeling of the steel coils to prevent damage during transportation and ensure easy identification and traceability. 8. Sampling and Testing: Conducting regular sampling and testing of the produced steel coils to assess their overall quality and compliance with industry standards. 9. Documentation and Traceability: Maintaining detailed records of quality control activities, test results, and product specifications, ensuring traceability and facilitating effective quality management. These quality control measures help ensure that steel coils produced are of high quality, meet customer requirements, and perform effectively in various applications.

- Q:What are the common methods of joining steel coils?

- The common methods of joining steel coils include welding, mechanical fastening (such as bolts or screws), and adhesive bonding.

- Q:I have one and need info about it??....It has a wooden case around the steel necks.and 20 strings,Twin Tens.

- well, it was made sometime before 1981, because that's when Fender quit making 10 string steel guitars. Without any more information than what you've given me, it could be the Pedal 2000, the PS210, or the Artist Dual 10. Fender made steel guitars from the 1950s through 1981, so it could be from any time in there. I hope you have the pedals with it. The 10-string and dual 10-string models were quite expensive in their day. Unfortunately, if you're thinking of reselling it, you're probably not going to get a lot of money for it unless you find a pedal steel player, and like I said, having all the pedals is very important in that case. Anyway, hope this helped. Good luck. If I were you I'd learn to play it. Pedal steel players are always in demand.

- Q:What are the different types of welding methods used for steel coils?

- There are several different types of welding methods commonly used for steel coils, including spot welding, seam welding, and flash butt welding. Spot welding involves applying heat and pressure to two overlapping pieces of metal to create a strong bond. Seam welding is similar to spot welding but is used for continuous welds along the length of the coil. Flash butt welding involves using an electric current to create a heat source between two ends of the coil, which are then pressed together to form a solid weld. These methods allow for efficient and effective joining of steel coils in various industrial applications.

- Q:How are steel coils used in the manufacturing of body panels?

- Steel coils are used in the manufacturing of body panels as they are rolled into flat sheets and then cut and shaped to form the desired body panel design. These coils provide the necessary strength and durability required for automotive body panels, ensuring that they can withstand the rigors of everyday use and provide structural integrity to the vehicle.

- Q:is broken steel the only fallout dlc that will raise the level cap from 20 to 30? also do i have to complete the main quest to play it? which fallout dlc do you think would be the best to get?

- Yes, Broken Steel is the only DLC that raises your level cap. Yes, you have to complete the main quest to play it. It's kind of a prologue to the events of the ending. If you don't have the DLC and complete the game it just ends and you can't play it anymore. With the DLC you'll be able to continue playing. As for which one to get, that's your preference. Most people like the Broken Steel because it has to do with the main story and it raises the level cap - so that's the one I'll suggest to you. I also think The Pitt and Point Lookout are worth getting as well. Mothership Zeta is the one I liked least. I thought it was kind of stupid, to be honest. Operation Anchoarge is a simulation and it's pretty fun, but I don't think it's worth the $9.99.

- Q:How are steel coils used in the manufacturing of metalworking tools?

- Steel coils are used in the manufacturing of metalworking tools by being formed and shaped into various components such as blades, cutting edges, and handles. These coils serve as the primary raw material, which is then processed and treated to create durable and high-quality tools that can withstand the rigors of metalworking processes.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PPGI/Pre-Painted Galvanized Steel Coil/Construction Purposes Az80-Az140

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords